2/4…

Nicest box ever ! May I ask how much it cost and the iner dimensions ? Looks perfect for your Raiden 7 89x83 mm

Going to do a “garage” anodization ?

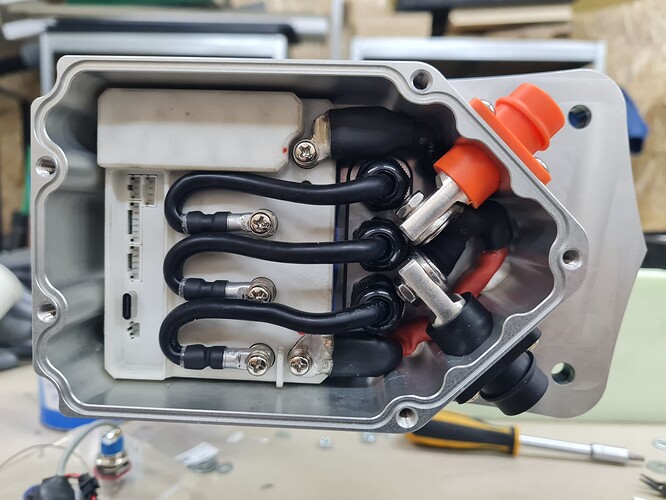

It is exactly for Raiden 7.

It was made by my friend quid pro quo.

I’ll give it to anodize to a local company.

Also some other smaller escs can be put inside.

Tidy build! How are you liking the Raiden7 VESC?

So much that I ordered another one for backup and maybe future project.

It is a good controller and not that expensive.

Alternative for me would be little focer.

Love the baseplate VESC box.

How did you manage to twist the three phase wires 90° coming out of the box going into the mast?

It does not look like you have a lot of room to play with when going through the cable pass through’s

Do you have some pictures of it with the wire shown?

Thanks.

It is an empty room of around 10mm. You can see it on the underside of the box. Otherwise the middle cable goes straight into the gland and other two go left and right.

I can show you the 3D cros section if you want.

I understand now.

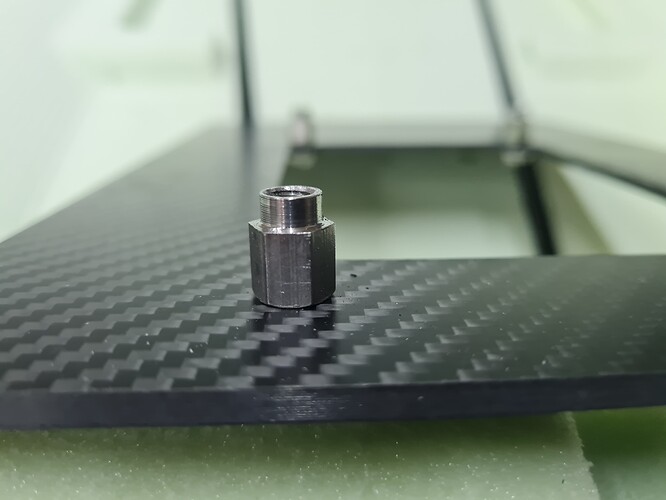

Looking at the gland in one of your last pictures, you have also put the “nut” at the bottom (me thinking that the nut side was in the box), so this will give you some more room to play with.

The box looks so sweat!

My dad and I are thinking of getting a CNC, but for this kind of work you need an expensive machine I guess.

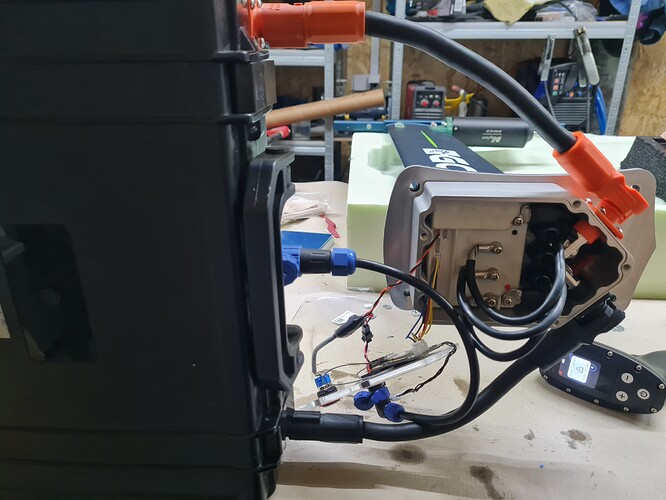

What’s the extra cable to the battery box for? Just for the switch to the BMS?

I can speak from experience… CNC 's are great (I have 5) but when it comes to cutting aluminium, a CNC milling machine will always win. Also there’s a point when cutting metals becomes more cost efficient to just get the component machined for you. Very often I do test components on either a 3D printer or out of a cheaper plastic on CNC and then get a machine shop to do it out of aluminium. That way I’m guaranteed a perfect part…

is BMS output that controls the enable signal for ESC. In a way it is a “power” stage of BMS. In this way I could put small BMS in the battery just for charging.

Me too. 3d printers are the best tools for prototyping.

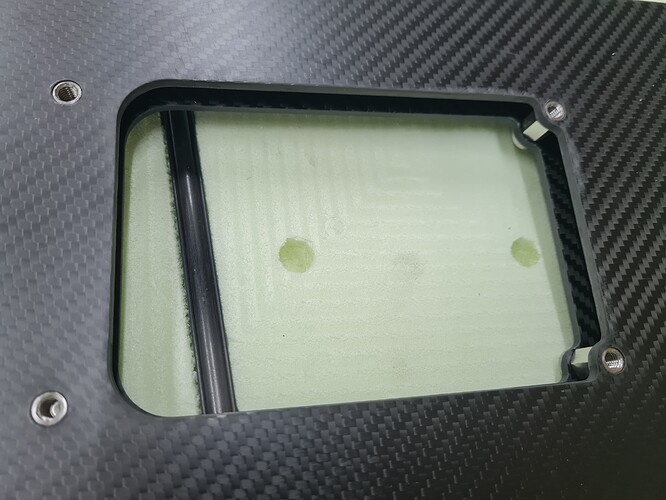

nose of the board has to be quite thick to make the mastpalte fit?