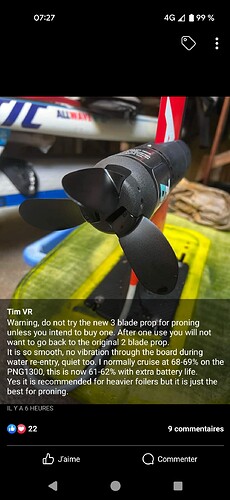

That’s clear, everyone is enjoying it.

Hope PropellerKing will do a hub for it’s existing blades

@Etiennebzh do you know where i can find a CAD file for a hub that will work with 3 aluminium FD blades? I was working on my own hub design and feel like there must be something out there already that someone is happy to share?

What stage is your design at? Can you share any interim results?

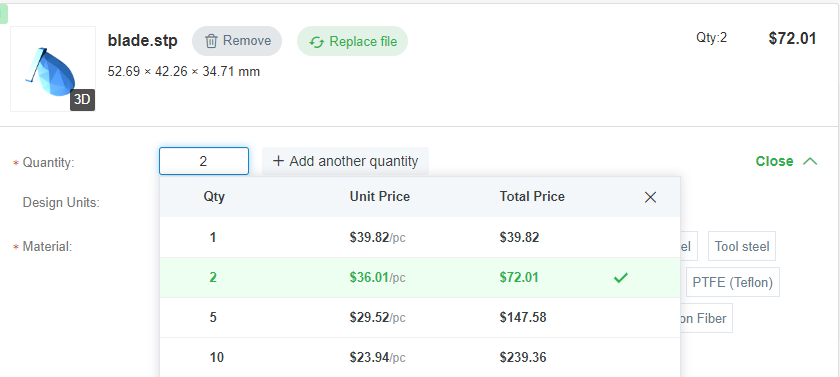

How much it costs to order CNC 3 aluminum blades?

(I try to get quote, but the stl of the blade is mulfunction)

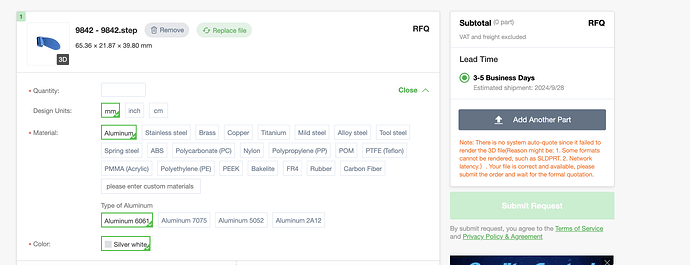

What are the required settings here? Like type of aluminum or surface finish and roughness?

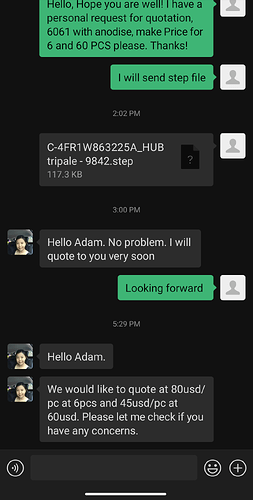

you can choose 6061 (std), 7075 (high strength) or 5052 (marine but low strength). I would take 6061 which is cheapest and add anodising. I don’t think they take stls for cnc machining, you need a real model like step or IGES.

Surface roughness doesn’t matter if it’s bead blasted (like they do before anodising), take the roughest.

Thanks @Larsb , it helps.

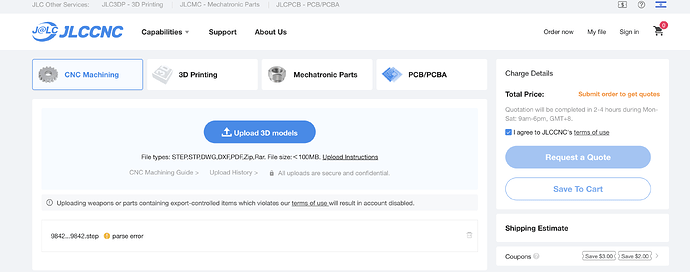

I have imported stl into onshape, exported step and uploaded that. But probably because original stl had errors, the website showed errors.

yes,probably.

The price per part is quite steep for 3, better make 6 and sell the set you don’t need ![]()

I don’t have any FD 3 blades prop hub file, I use the original one.

BTW, here is the link from @Bzhwindtalker design, you should find his blades also. Tks to him !

@Larsb Where did you get that stp, can you send to me?

Where did you do the quote?

I tried now the @Bzhwindtalker blade, it does not have errors, but when I converted it to step and uploaded, both JLPcb and PCBWay reported an error…

Look on the bottom:

Look on the right:

Pcbway. I hacked that blade, 2 min job so it’s just a dummy to get a rough quote

Parse error… i don’t know. But if it’s been an stl you could get corrupt surfaces. If you open the stl in a slicer, is it intact or is it open?

You could try saving in a different step format, or as iges. Might just be lucky ![]()

Yes, great ideas!

Hacked blade! ![]()

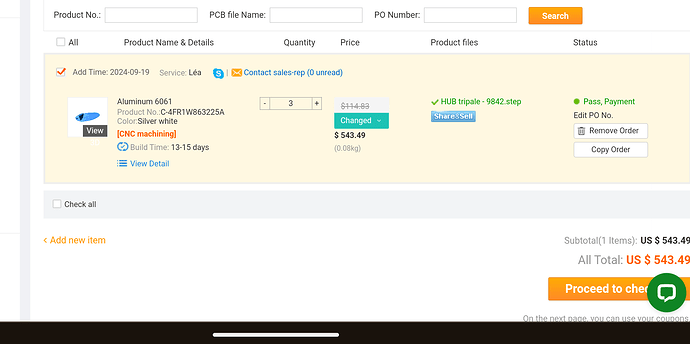

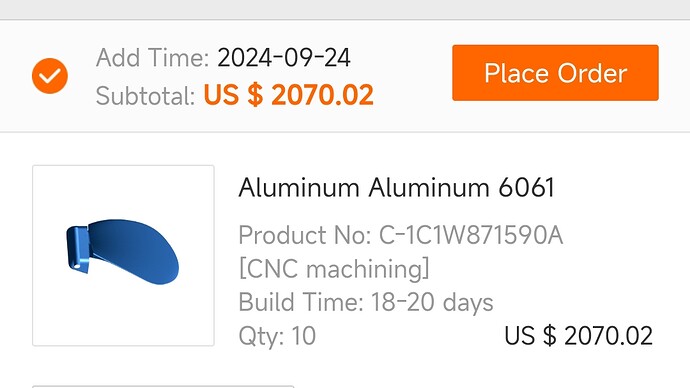

My request has been approved from the step file, but as you Can sée, the quoted Price IS much higher then the displayed price !!

This IS why this kind of blades need to be mass produced… Can be much cheaper

And I got also similar price for an approved request:

May be that the file corruption or the unneeded complexity of multiple surfaces causes such a high quote.

I don’t think that blade suitable for aluminum anyway - it is too sharp.

I requested a quote to my aluminium CNC supplier in Shenzhen. They produce a lot of 5 axis parts with complex shapes, precision not Always great but better than 3d printed ![]() , so they could be competitive. I will report back

, so they could be competitive. I will report back

Why do you want three blades? afaik lower efficiency, will cost more, more parts, harder to make robust blade roots. Is there enough benefit? I see the original post but might as well be a sales pitch?

Much quieter, no cavitation.

-less vibration

-more thrust at same rpm

-better stress distribution onto three blades

Are you referring to this particular design or in general? vibrations are surely better but the others depend on blade design and area, i don’t think that there is any physics that stop a 2-blade having same thrust as a three blade. Maybe the folding function putting constraints on the blade design?

From my limited experience 3 blade has much better surface piercing performance than 2 blade