Good evening.

Just giving the FD motor a bit of a touch up and noticed the pattern around the magnets from the undercoat. Just curious, does the number of poles determine the kv?

That’s a great idea.

I was thinking about backpack straps of some sort.

it’s likely that for Assist PLUS they are using a VESC. They posted a video with many features that you can only get when you sync the may tech receiver with a VESC.

I just bought a maker X SV6 that is going to be pretty excellent for that purpose.

https://www.makerx-tech.com/collections/x-esc/products/go-foc-sv6-high-power-singel-drive-vesc-100a

Thanks for the info.

Will a 6s4p made with 30q cells deliver enough current (15A x4=60A) without getting too hot.

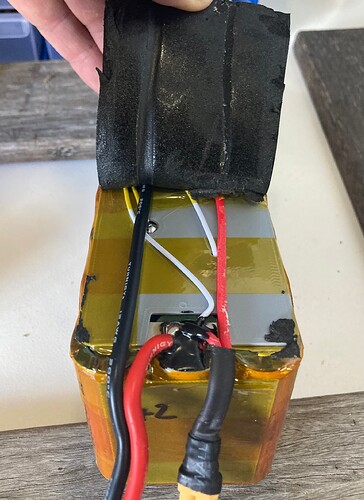

I’ve pulled the shrink wrap off my FD battery and noticed they use exactly as you mentioned. 6s3p of the 21700 P42A.

Does anyone know how much current the foil drive motor draws?

I’m in ISO and don’t have a clamp meter.

Cheers

My 6s4p 18650:pack has been performing well. I never use it in efoil mode. Just short burst to get going in the ocean bumps. My next pack will be 6s3p 21700. Just had one built using Samsung 40T. If you any photos of the FD battery without PVC cover that would be great to see quality of the connections and balance wiring.

I’ve put the 3M 5200 and it takes A WHILE to cure. After 2 days it’s still a bit tacky. I’m not in a hurry but compared to Sikaflex F11C… it’s VERY VERY (VERY) LONG. The bond seems very good.

@cephalofoil according to the p42 cell datasheet and also my crude math, you should expect a voltage drop from 4.2v to 3.6v@40A discharge rate.

So in theory (to MY math) your FD 6s3p Li-ion pack can “safely” deliver 126A continuously at a voltage of 21.6v, so 21.6V*126A = 2,721.6W

Personally, I wouldn’t push this battery pack past 1000w continuously.

Don’t tell my Math teacher.

Thanks Eden.

What I am curious about is can I expect a similar performance with an 18650 pack (6s4p of 30q cells)

With a reasonable safety margin?

Should I try to make a 6s5p or would I be better off buying new cells and sticking to the 21700?

Cheers

yes you are right this vesc looks promising . So for motor what is best solution for 8s and rear mount ?

for the VESC, I will be testing it back to back with my current traditional ESC and good thing will be the telemetry, to better see what is going on.

When it comes to 3M 5200, it’s a long road that requires patience. I’m going to slightly sand the area and add a bit more 3M 5200 on the joints below to smooth things and a bit on the inside to ensure a perfect seal. That’s more or less a 2 weeks journey to allow the 3M to dry appropriately

3m makes a fast cure 5200 that is easier to work with and still retains all the properties of the regular 5200.

yes, spot on… but I took the normal cure! Next time, I will go with the fast cure. No doubt!

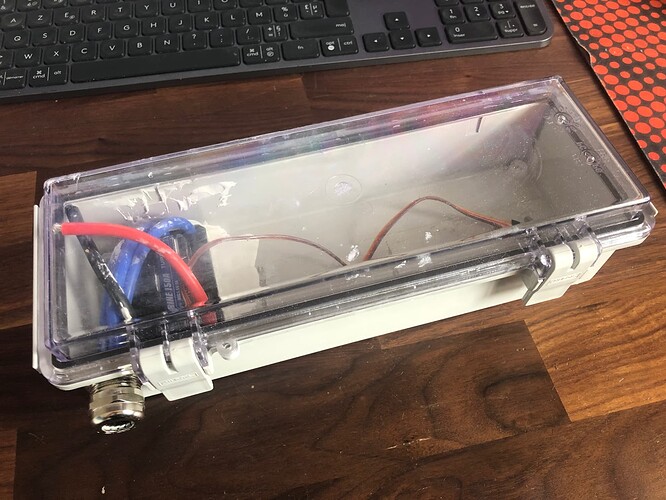

Are you letting the esc into the bottom just for cooling? You mentioned earlier that you needed the space but there looks like room for a receiver. I’m as anxious as you for your 5200 to dry!

Scott

yes, in my other (working) build, I put the ESC inside the box and it was getting up to 70°C. With this option and although it’s plastic, I often throw water on the board and below. This will for sure help in cooling the controller. For 5200, it’s just a matter of time. 7 days is a good target for a full dry (and waterproof testing). If that works, I’ll be switching to the MakerX in my first build and also dig the enclosure.

I understand correctly that you are going to cool the plastic part of the ESC case and think that this will be effective?

ehhe, well yes, it’s probably stupid but probably a bit better than cooling nothing, or equally similar to my other build which works pretty fine

Through the opening of the ESC box, if the ESC surface is in contact with the board pad that is regularly wet, this could become a good solution … Maybe adding a piece à fabrics (sponge) between the pad and the ESC could keep enough humidity to cool the ESC significantly down …

A nice way for passive cooling: is to get a aluminum plate 2mm the size of the bottom of the case, cut the case the size of the esc , glued the plate on the outside of the case and put the esc through the cut on the plate , pressure hold , padding …

Can be done on bottom or top , the full plate will easy waterproofing and rigidity

Hey guys,

I tested these days my setting designed exclusively for winging. Some minimal support while pumping to get on foil.

Low thrust, but therefore low drag and low weight. It worked out pretty well for me.

Flipsky 5062, Flycolour 70A, 6S-Battery, Maytech-Controller

The mount of the controller (with the help of a 3-D printed box) worked really good. I could concentrate on pumping the wing without being disturbed activating the trigger.