Yeh I paid $87 (aud) for a 6384 120kv last year.

I can’t comment on quality though because it is in pieces waiting to be modded. I have the ceramic bearings ready to go just need some slow cure epoxy.

On my list. Haha

I don’t think the Saite engine is the “best” out there…its a simple engine which is easily replicated by most Chinese manufacturers making these things…FD probably just found they could get the cheapest deal through them initially and voila !!!.. all they’ve done is epoxied the stator coil…and put in non corroding bearings all of which can be done yourself and relatively easily. I’ve got two of these and they’re really basic with basic epoxying…they’re not finished all that well and have a bit of 3 core flex attached which will need redoing as it’s all a bit messy…

Like some , I also went to Saite because I didn’t know as much as I’ve learned about all this now and thought its just easier to get the same product as FD. After some really good advice from some on this forum I also now know that

you can use pretty much any engine of the 6374/6384 spec with a lower rated Kv and get what you’re after…

I’ve been looking at other engines (flipsky, alien power etc. ) and all of these would work very well…the main issue is that their physical design(s) vary (mainly to suit a cleaner/tidier ESk8 function) and that will affect how you mount the engine to just about any motor pod design out there currently; these being designed around the “older” Saite style outer housing…in short all the mounting holes will be different (if they exist at all)…I see that Flipsky have now gone for a flat blank hole less end cap which is really tidy for an eSk8 look but useless for an FD as you have nothing to mount the engine to !!

So you’re CAD skills need to be adequate to make the required alterations to make everything fit !!!..its all part of the journey and there is no quick way around it.

KONUTZ

Thanks for the info. I find that the cheap 6384 120kv does the job both for foil drive and efoil, and since it is cheap, it is not a big deal if it breaks under heavy load. The Saite looks a bit more refined, but might not be much better than other motors. As you say some of them lacks mounting holes for propeller or mount so it is better to stick with the ones having 4 screw holes on both sides.

Found this 54.4usd total on Aliexpress: https://www.aliexpress.us/item/3256804194195478.html

Is it reasonable to buy it cheaper than that on alibaba, here 39.99usd for a 3600W with trade insurrance ?

There are differences in what is called 6384 motor, the cheapest ones have 10-15mm shorter stator and can therefore not produce the same power or torque.

I don’t think 2/3 of a 6384 is enough to get up so that really matters.

My advice to anyone buying a 6384 motor is to ask for the stator width, if seller doesn’t know or won’t give you an answer then think twice about buying if that exact motor isn’t already verified to work in efoil/foil drive application.

I’ll see if i still have a fake ”6384”, then i’ll upload some pics

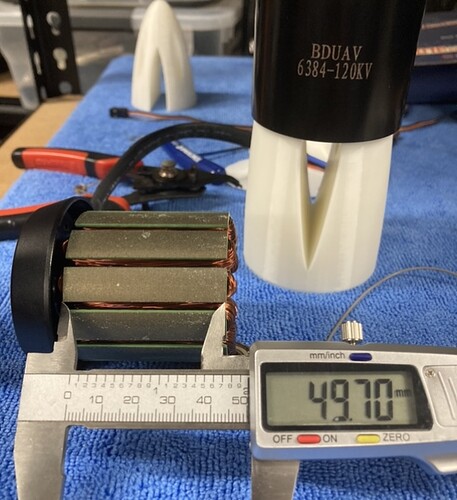

Yes, I have read that the stator length varies, but probably not by 10-15mm. The Saite looks identical to the APS motor and it was measured by @PowerGlider to 56mm stator and my $50 motor was about 50mm, so it is more like 10-15% difference. As I mention in my build thread, this motor works fine for efoiling, so at the price it is a bargain.

Now I’m working on a FD/efoil hybrid, with a 800wh 10S battery and the same motor.

This is in no way meant to rag on foil drive. I absolutely love their product and I would recommend it to anyone. But my intent on being a part of this forum was to recreate what they’ve made simply because I felt it wouldn’t last in the marine environment.

Although I have been meaning to open their motor for a while, I only opened it tonight to measure their stator.

Please note this motor has been rinsed and sprayed with a salt away product after every session.

Already here we see 56mm (if that was powergliders number) to 46, that’s 10mm and 20% less motor

So a 6384 instead of a 6374

That’s ok, the owners are on the forum. This is where the product was developed before it went live.

The upper BDUAV 6384 motor is the one I got, which is 50mm, and the lower is a FD 6374. For 8-10S I don’t see a good reason to choose the 6374 over a 6384 though, for heavier people at least.

*runs to measure the 6384 he has here…

My AP 6384 has a stator of 56mm. It would be interesting to see if the FD motor actually can handle the same amount of power as the AP motor.

Answer is naturally no, question is more where the breakpoint for function is. Do you lift without paddling on the 46mm stator? At 50/54/56? at which weight and board float?

I just measured what i have here:

Torqueboards 6380 is 54mm wide

Noname 45$ “6384” is 50mm wide

(I screwed up the caliper location on the pics but values are correct)

The torqueboards motor has 10awg wires

(which will need to be extended)

The noname motor has 16awg wires

(which will need to be replaced)

No big difference here.

The torqueboards motor magnets are stronger, it’s a fight to get calipers released after measuring

Great initiative. Why a non rusted motor on pict 1 and a rusted one on pict 2 and 3 ?

We are at the heart of the DiY: caliper in hand, are all 6384s equal and if not, on what criteria should we be vigilant?

pic 1: DIY motor

pic 2&3: Foildrive motor

That FD motor is going down the drain already it seems?

Stator steel might look bad but takes a long time to really make a difference whereas the magnets go quicker when rust has started to show. One or two magnets puff/crumble and then the magnetic balance of the motor is gone.

Hello, I have treated a 6384 with slow curing epoxy and the truth has surprised me what has happened to me. I didn’t get to touch the water and there was a problem in one of the wires that fed the motor, it got very hot for a few minutes and what I show in the photos happened.

I have no problem having to replace a motor every 6-8 months, the pleasure I get is better than the constant investment. The problem is that I don’t know if with epoxy I will have that flaking in the block of the epoxy itself or go towards corrosion X

Put ceramic bearings in it and soak in corrosion x every 10 or so uses in saltwater and enjoy the ride. My original setup maintained this way is going on 15 months old without any issues.

!

Hard to see what happened but I think you put far too much epoxy. Just a dip to cover the stator should be enough. Water should still be able to get to the windings to cool them.

+1 on that!

You can only pot the motor fully if you use thermal epoxy or silicone, with normal epoxy it will overheat.