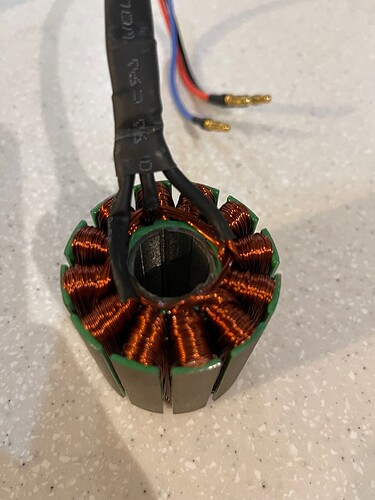

Does the pin lock the stator housing to the windings?

I’m going to try free mine up today.

Ya it just keeps the stator from rotating on the black housing. The black housing has a slot that the pin goes in and then just line it up with the slot in the stator.

Thanks for this. That is really useful.

Strap Motor mount for 63mm motor and Gong HM Carbon Mast by toto45 - Thingiverse

I hope I can test mine next weekend, so if you use this, please consider it untested!

No problem at all! This forum has been such a help/inspiration to me that I want to contribute in anyway I can to help out!

I’m so glad it was helpful!! Let me know if you want to see anything else!

If you get a moment, it would be great to see how you have joined your cable to the copper windings and insulated it.

I will try and get a video done by Friday and post it for you.

I have an old 6384 100kv I need to take apart in order to resolder… Only problem is the top looks threaded and it’s also epoxied at base…

Any one have any wise ideas?

This is the alienpower 6384. Great motor if I can get it apart and resoldered… That will also mean I can waterproof it a bit better.

I did try giving it a knock but no movent…

Why resolder it, is it shorted?

One of the cables snapped off right near the stator housing. Figured if I can take it apart I can just replace all three cables.

is the black housing actually threaded to the stator? It’s hard to tell in the pictures if the housing sleeve goes all the way up.

If its not screwed together, which I dont think it is, I would heat it up with a heat gun and beat it.

It does go all the way up. It’s very hard to tell if it’s just a top piece that’s threaded.

My guess is the housing is not threaded to the stator. It wouldn’t make sense because the housing is aligned to the stator with the pin and you can clearly see the alignment slot cut. I would try and heat it up with a heatgun and pound it out like in my demonstration video.

It looks like there is a very small lip to make contact with a socket or bearing removal tool, so make sure it fits really good on that lip.

Hi everyone,

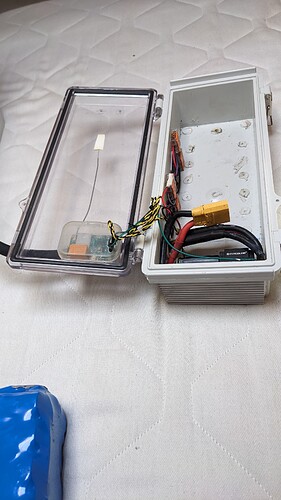

Happy to share that I found a perfect nimble ESC which fits very well on the width of the box.

Flycolor XCross 160A. 2 heatsinks on it, one is connected to my outside heatsink. You’ll have to weld motor wires at 45degrees and go !

Firmware is BLheli32, lots of settings and easy to adjust with a cheap USB tool connected from the ESC and my phone app.

Good for heavy riders

BLheli32 - that is a drones thing.

Which software you use to tune it ?

You connect to it by usb? Can add a bluetooth adapter to it in order to connect without opening the box?

Can you tune the start up current?

Able to save logs?

Does it include BEC?

Please explain and put pictures if possible - how did you attached the external heatsink to the box and attached it to the esc.

Please update us with the actual performance in the water…

As I collected information for the build, I have created this knowledge base. It is in it’s initial stage.

I would love if it becomes an ordered and accessible source of information for all of us and especially these beginning their new build.

Software : Blheli32 Android open source app

Hardware : Aliexpress Blheli USB programmer connected to my phone with the “3pins esc to receiver cable”

Bluetooth: Not found

Startup current: Rampup power in % and Acceleration in %/ms and max current also

Save logs: No

No Bec

I only use plug and play ESC, very powerful and sensitive trigger. Don’t know Vesc

Heatsink: Cut your box, cut an aluminium plate to replace the plastic meat you removed, and stick the back heatsink of the X cross on it with thermal paste.

I’ve nothing special to tell about performance because it’s a foil assist, I don’t measure anything, just burst and take off and use it sometimes longer to go offshore, it handles the temperature very well.

I’ll put some pictures later

I’m looking forward to seeing the pictures. It sounds great and it is good to hear of other inexpensive options.