They just invented efoil

I think the major advantage of foil assist is the quick assemble/disassemble and adjustable height…

Is the cable drag so important ? I mean their propeller doesnt seem very hydrodynamic (on the end)

Does anyone know which compound was used?

They remove the retaining ring from the shaft for ease of maintenance. This may not be safe.

The cable integrated in the plate is really interesting… flush with the board bottom means hardly any drag and no hole in the board… Wondering if other brands will go that path …

What would be useful would be a FoilDrive unit whose height could be adjusted along the mast while riding from a flexible handle above the deck (flexible spring).

To minimise the drag, the wire would be concealed in the leading edge of a 3D printed telescopic mast protector with a airfoil section.

Good luck with that. I want to see the foiler with a remote in one hand while trying to adjust the height of the motor in the other, all while on the foil.

Foildrives videos on the project cedrus mast give interesting insight into motor height.

Of you look at the efoil/assist market you’ll notice the best selling products are the simplest products with as short as possible setup time. Complexity introduces loads of warranty returns!

I’m just suggesting  . You know how things happen : yesterday’s utopias (Inkjet printing, 3D printing, kite/wind/wing/e foiling, …) become today’s realities when someone finds a way to make them happen with less complexity…

. You know how things happen : yesterday’s utopias (Inkjet printing, 3D printing, kite/wind/wing/e foiling, …) become today’s realities when someone finds a way to make them happen with less complexity…

If @jetsurfingnation can do a board grab twice in the video below his feet level, I’m sure he can do a “handle grab” at knee level

May as well add a second skinny mast in a sliding channel which holds the motor…

Because there is some torque on the mast with possible sand, I suggest a pod assembly nose including two translation rollers rolling on the mast leading edge side like an OpenBuilds CNC rail plus another small roller on the trailing edge. The issue remains the motor cable that must be collapsible: CNC-like cable tray or reel like the 2001 reel leash from Oceanus still available…

May as well run a channel that’s used to lift the motor up and down with the wires inside it. You’d need 3 rollers and need to replace the rollers when they wear down. Then if sand gets onto the rollers they’ll struggle to run smoothly. Endless maintenance fun…

Fliteboard did make that choice for their True Glide Prop running 50 to 95% of the water time and immersed 100% of the time… A motor pod roller with adjustable height would be used a couple of minutes per session. If not in efoil use, the immersed time woud be quite low.

Instead of using a roller against the mast, a translation guide could be made out of a low friction material like Nylon though.

The truglide prop is nothing like you suggesting. They have sealed bearings so that sand cant get anywhere near them. The truglide prop is super low maintenance.

Also by simply placing a foildrive 30cm below the board and 60cm above the foil you are able to both efoil and freeride, completely eliminating the need to move it around by hand…

In the world of watersports, simplicity always wins. No one really wants complications and long setup times.

Are they available on the market ? Any equivalent ?

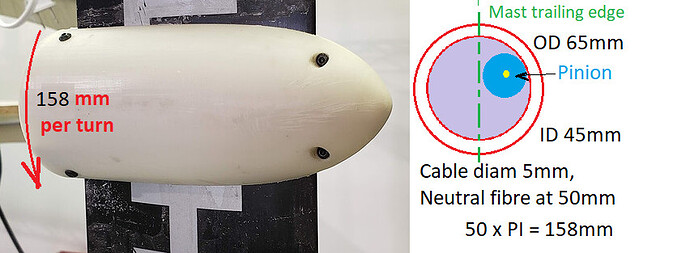

Rolling the cable around the motor pod would be a low maintenance solution. One cable turn (OD 5mm) around a 45mm section represents a cable length of 160mm. A 3D printed TPU friction roller (blue on the diagram here below) fixed between the mast trailing edge and the reel transforms a longitudinal movement into a rotational one to wind/unwind the cable that is increase or decrease the motor cable length along the mast.

A single turn allows the pod to range between 100mm and 100+160 = 260 mm below the board bottom which is roughly what is described in the @jetsurfingnation video.

I think using a single sheathed 3 core cable doesn’t make sense in a foil drive. Comparison of 12 AWG 3-core cable and 10 AWG cable holder

Love the crazy ideas. Here’s one to add to the mix.

You could use water pressure from a hole on the front of the mast to force a magnetic puck upwards inside an aluminium mast, pulling the motor pod upwards.

The cable could be coiled at the back like you suggested.

What truly blows my mind is how the foildrive users spend 3k on a unit and then don’t just get an extra mast for $100 so they can run the cable internally!

The people who spend 3k on a foil drive unit aren’t the same people that will diy install a cable inside a mast.

Hahaha very true! But they could pay someone to very easily do it…