PVC flexible skirting band looks like a possibility - definitely a step up from duct tape!

We were standing and cruising around at 5mph to play with balance. My HIPE is 145L. I don’t see the difference between kneel and stand since that changes nothing below the board. Am I wrong?

That should help to move mast back though - thanks!

I did a lot of nose up plowing through the water stuff when I first started. I had the same motor, battery and foil as I have now. The board would even start to lift out a bit but then the pitch angle up would get even more acute and I would have to let off the throttle and the board would slam down. NOT FUN AT ALL😀

I watched some more Tube vid how to stuff and then it finally sunk in what I was doing wrong. Not enough board speed on the water BEFORE trying to fly.

When you visualize or recall how a plane takes off it rolls flat down the runway until it gets up to speed and then the nose lifts up gently and your flying.

If the pilot tries to take off too early in that sequence or tries to climb too steeply bad things happen.

The learn to fly while kneeling before standing is how most people learn and is how they seem to teach it at “learn to foil school”

Less chance of falling off and getting discouraged or injured I think is the theory

try it, you will see it changes a lot. you can balances the board so that the nose touches the water but does not dive, so you start to plane. then you can fly on your knees or stand up

of course it is possible to get on foil from standing position (with a big enough board), but its much more difficult. so not the best way to learn

same as starting to learn with a more advanced wing/stab. the x-over you have is very good to learn and makes fun for a long time

On my first test with a 6384/10S/Gong Fluid XXLS I also had cables outside, but taped neatly behind mast to reduce drag, and also a proper mast mount for the motor. The drag was siginficant and hardly got foiling. I then put cables inside mast and that made a huge reduction in drag and got on foil easy. So having cables outside for e-foiling will never work and combined with that draggy motor mount it is even more hopeless. So get a 3D printed mast mount and put cables inside and it will be a world of difference. And of course a higher currrent capacity on battery, as mentioned.

Hey guys, I was also going to have wires neatly tied down to the mast, until I saw this post.

Problem is it feels like my carbon mast is completely solid (at least to me). I drilled a small (30mm deep) pilot hole into the top where it mounts to the board, and also in the side where it’s still covered by the mount, and it was solid. See pics

Any chance it’s hollow into the middle of the mast so I can route wires? Any other suggestions or good news? I might have backed myself into a corner here.

Your link doesn’t work for me but I don’t see any logo on the mast itself so can’t realistically comment of it having channels in it. However if it really is carbon it would seem unlikely they would make it solid as that would logically cost more to build and you wouldn’t need solid to make it strong anyway.

I will comment on your taping wires to mast and your prop.

I started out with wires external and using the full size Flipsky prop supplied with the 65161 motor they sell. Looks the same as yours.

The rig worked OK but things didn’t feel or sound right.

Lots of comments here about that prop being too big and that is good advice. I reduced the diameter of the prop down to ~145mm and the ugly sounds went away and it felt like I had a different motor. Major improvement and possibly saved myself from an early motor failure.

Next thing I did was route the wires inside the mast which meant giving up the flexibility of moving the motor up or down the mast that I initially wanted. Again it was like I was on a totally different setup. I would say an overall 25% improvement in performance getting rid of the drag induced by the wires and the hydrodynamic trailing edge wire holder I 3D printed.

I was also thinking there’s no way it would be solid, but it feels solid to me. Those two places I drilled in were solid too, and I’m hesitant to drill anywhere else.

Maybe someone here has an approximate weight for an 85cm mast only that I could compare to?

I was planning to route the internally but I may be stuck on this one…

Do you have a link to 145mm prop?

Not sure about the link, looks fine for me.

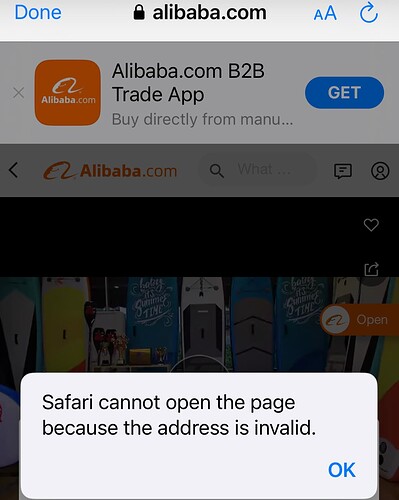

This is the error I get on the link.

The mast doesn’t “look” carbon to me which doesn’t mean it isn’t. If a component is marketed as “carbon” it’s common to be able to see the carbon weave fiber in the layup.

I would look at prices online of brand name carbon masts and compare that to what you paid. That might be clue. Your idea of weight has merit as well.

I didn’t buy a 145 prop I removed material from the original aluminum prop. Some people here have extensive metal working tooling and expertise. I did mine with hand tools and it works fine for me.

Try this link:

Thanks - This link works but the detail in the add isn’t claer whether a component is aluminum, carbon or some weird combination of the two materials.

At one point they say All carbon is $X or All aluminum is also $X which is a clue as manufacturing costs would logically be different.

If you compare the $ in the add to say the Gong products often used here it’s a clue to what All carbon retails for.

@SanguineDrone That doesn’t mean that your mast is bad but certainly harder to determine what it’s made from or if there are usable voids inside.

This is a post here where it looked like they used a really long drill bit to make channels in their mast. Also search “carbon mast” here for other ideas.

I messaged them and they say it’s carbon, waiting to hear back if it’s hollow.

It looks, sounds feels, and weighs like (soild) carbon to me. It’s definitely not metal. On the edge I can see what looks like layers. Maybe it’s black fiberglass  ?

?

Regardless, I think I will try my best to drill it out with a long drill bit.

I have a similar set up - I think you need to change the propeller too as the stock one from Flipsky is too big. I use a 3d printed one of 140mm diameter and around 6in pitch.

It’s pretty typical to do “sandwich layup” in fibreglassing. Light inexpensive core material like foam and then layers of glass around it. The “sandwich” is often stiffer and lighter than solid. I haven’t worked with CF but I think the principle is the same.

Maybe you will luck out and find the centre core is foam and the drilling is really easy!!

To start with I used the Pacific Meister parametric prop and duct which worked fine even if not the most efficient.

I have since designed my own with the online tool here :

Thanks guys, sounds like I’ll have to do something about the prop too.

It worth it and really not that hard to accomplish. Carefully measure and mark each blade using the center hole as the starting point to get the desired diameter or slightly larger. The material of the blade is thin aluminum (I cut mine using a dremel with a cutoff blade) and then finished the rough blade ends with a grinder (I can hear the master metal workers grinding their teeth already  )

)

Mark each blade differently and then spin the prop horizontally on a piece of rod. If a blade ends up at the bottom repeatedly then take a tiny bit more off. Repeat until there is no more bias of a blade down and the prop is balanced

And when cutting and balancing, try to maintain an even shape on the blades as well. This helps with thrust balance.