Yes, thanks, realized after I posted that balancing was still needed and the parallel count is irrelevant.

I’m curious about how you are finding the

wing.

I am working on a video with all the info, so stay tuned for more details.

~Spoiler: It’s a great wing with a wide speed range. It’s not really made for general cruising (it’s sensitive in pitch), but for having XXL fun, it’s a great wing. I’m even starting to use it for jumping. (still need to work on the landings ![]() )

)

Awesome looking build! Im wanting to do something similar, did you remove the original aluminum heat sink and mount the circuit board directly to your aluminum plate or did you machine the fins off the original heat sink and mount that to your plate?

I removed the casing from the 75200, and fixed the PCB bottom (with cooling pasta) directly to the aluminium baseplate.

So basically it is mounted exactly the same as it would be inside the original casing.

Thanks for that. I was hoping that was the case. Ive also got a 75200 vesc ready to go.

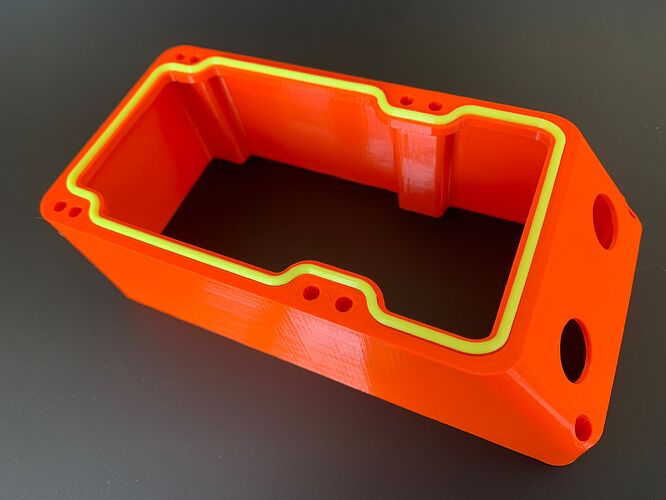

@Kian could you please share the box for the esc that fits on the adapterplate and also the ninjaflex sealing, because I will build exactly the same. That would be great, thank you.

It may not actually fit right into the Flite air.

I have a regular carbon Fliteboard and a Flite air. The shape of the mast box where it meets the battery compartment is slightly different between the two. They are both compatible with Flite’s own masts of course, but I needed to cut a small bit of plastic out of the Flite air to fit my mast on the air board. I don’t have the same design as @Kian though, so I don’t actually know. Just be sure to test fit before doing too much work

@sharrow Here you go, but as Silias mentioned, it might not fit.

The .stl file’s are all I can find at this moment.

https://drive.google.com/drive/folders/1h_YIV13AHpmnKW-YCQYRxoIEM1UxohTe?usp=sharing

@Kian thank you very much that helps me a lot because I am no cad specalist. Will try to modify with fusion 360 if necesarry. Which screws and srewholders are you using. How the screwholders are attached to the esc box? Only hammered them into the case? ![]()

No… No hammering. We used a thread tap.

I can not remember the size, but I believe it was M4.

I mean this ones for hammering. Did you use this?

And with what Kind of glue did you seal the esc itself.

https://foil.zone/uploads/default/original/3X/0/0/0068a4db026f91a50a1ea75ac5018650ef57e042.jpeg

I found the solution

Aha. Yes. I used a soldering gun with a special tip for it.

Nice build, congratulations. One thing I wonder: the pouch cells are said to be 310 x 114 x 15 mm in size. The Fliteboard room for the battery is 305 mm wide. How did that fit because 3 cells add up to 342 mm plus case?!

Hmmmm…

You are correct. I guess the size shown on the datasheet is incorrect?

As you can see in the pictures, I do have three next to each other (3 stacks of 5), and if you zoom in, you can see that they are LG EB63B pouches!

I have one left, and will get the size of it for you.

Not my picture, but this explains a lot.

I will measure the one I have left here and post the measurements.

Did you 3d print the gasket in tpu? I have always wondered how that would work.