Hi “lukmo” I` am new in this comunity and I saw your nice work. If you agree and you have some minutes to spend for a short chat, It is possible to get some info by phone? I am from Koper, SLO.

Yea sure you can PM me and I can tell you my social media or something… but if you really want to know the important stuff about building and everything, you show ask @flytomaz for sure. He is feom Ljubljana and he helps me too. Let me know what you need…

Br Luka

Hello guys!

Long time no see, I had a lot of school work and a lot of exams, so my project kinda slowed down a little, but I am back now! My board is CNC mashined (i will post some pictures soon), and now I have to deal with small details and after that i will laminate CF.

Since I have 100KV 65161 motor, I will need suitable prop. I ordered the new 2023 FR ULTRA prop 6inch. Do you guys have any expirience with this prop, how does it perform?

Thats all for now!

Hey Lukmo

We used to use a diode as a snubber to suppress back EMF in industry, it was only for low current applications like relay and contactor coils. Don’t know how applicable it is for a high current requirement. I haven’t seen it mentioned as an option so could have been overlooked or found not suitable.

Cheers

Hello guys,

can anyone recommend anything like a reed switch that latches (when magnet is close it closes clamps and when magnet removed it goes back again in open state), so it send a signal to my ant bms. It would work like a push button and send a signal. This solution has to be very reliable, because it will be in my battery case which is sealed and glued, so it would be hard to repair if something failed.

Hi Lukmo

I have never come across a latching reed switch only momentary. If I needed it latching I would have it operate a latching wired relay. However then you need a condition to unlatch it. I have used simple security door reed switches for industrial applications or you can purchase the reed in a glass envelope as a separate item from the likes of RS components or a similar supplier.

Note if you are going to use a reed switch with a magnet to maintain closed status, that vibration or jarring might momentarily drop it out and cause power disruptions. Also if you use a relay for any control operations, I have encountered vibration issues with a standard industrial relay like Omron MY4N and had to change to auto relays (which I think have more robust spring assembly). Cheers

Hi an update to my original comment.

If you go to @JP833402 posted Jan 21 he has found a normally closed (N/C) magnetic switch from

It was posted on @jeffm

Efoil V3 - STL files for Gong foil and Flipsky motor 12mm - Parts list – Schematics

The thread and others by @jeffm has lots of excellent information for DIY like Bill of Material spread sheet, schematics etc.

What about a Bluetooth BMS and just use your phone to turn it on and off?

I have Bluetooth ant 150A BMS, so I will have 2 options:

-bluetooth app

-reed switch

The problem is my battery case is 100% carbon fibre and I dont know how does bluetooth penetrate thru it?

It is really unconvinient that you need phone on the beach to turn it on…

Thank for all the help and tips

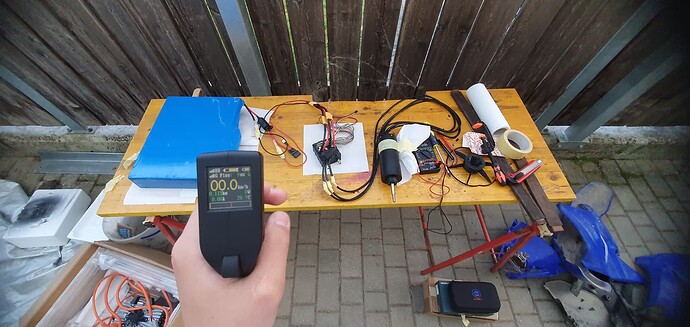

I made some progress with board and electronics, I set up a plan to finish my build before 15th July, because on 17th I am going to Croatia and I would like to have it working by then. Here is a photo of trying the electronics. With help of @flytomaz we filled the motor with shimano mineral oil. I will post more photos of the board and everything else later.

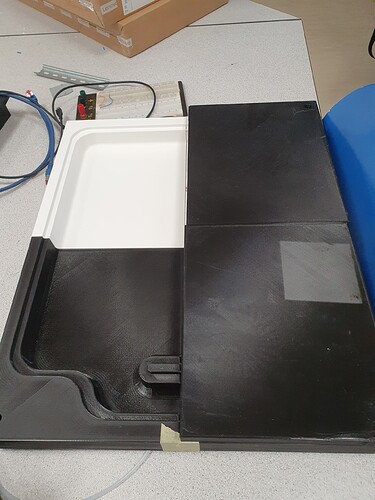

Molds are 3d printed and next week I will be hand laminating CF with vaccum bagging. I should get pretty nice battery case. The size of the case is the same as lifts.

Hello, everyone,

I wanted to provide an update on the progress of my project, particularly the board. My initial goal was to have it completed before the 17th since I’ll be going on vacation. However, it seems like a bit of a mission impossible to achieve that deadline. If it were only a matter of finishing the lamination, it could be possible, but I also need to create a battery case from carbon fiber and put in a lot of work on inserts for the handles and other components. I plan to resume working on the project once I return from Croatia, and hopefully, we can have a tryout on Lake Bled. Perhaps we could even involve some other builds from Slovenia?

I really like the look of your board. Did you cnc or hand shape? Do you have cad file to share?

Thanks

Well I got the pro licence for the board shaping software called Shape3D. I drew the board there and with help of Slovenian company Flikka boards, we managed to cnc mill the board. I tried to convert the shape3d file to step, but I did not get perfect results. I can PM you the file if you want?

BR

yes please I can see if can get shape3d to have a look. cheers

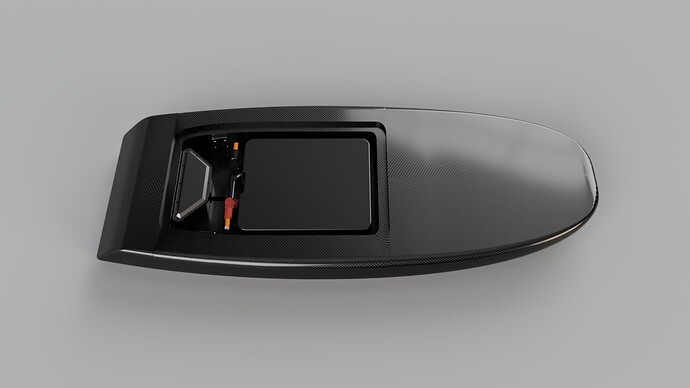

Exciting Updates on My Efoil Project! ![]()

The past few months have been a bit slow for my efoil project, but now I’m back in full swing and nearing the finish line. A huge shoutout to @Felixfoiler company for their incredible support! They generously provided me with a remote, and I must say, I am thoroughly impressed. This sponsorship has been the final push I needed to bring my project to completion.

I’ve been hard at work conducting various tests, particularly with resin infusion for different parts of the efoil. One of the key components is the battery case, which I initially created using 3D-printed molds. Unfortunately, my first attempt was not successful due to using the wrong epoxy and mold materials, resulting in everything melting down. However, I’ve now upgraded to high-temperature filament and the Bambu Lab X1 Carbon. With these new tools, I’m in the process of perfecting and smoothing the molds.

The efoil lid, which I stand on, has been a significant success. One side, where the gasket will be, is perfectly flattened like a window. I plan to finish it off with a matte black paint, just like the battery case. Both the battery case and efoil lid are made from fiberglass, not carbon fiber, to avoid interference issues.

My project is coming to an exciting end, and I can’t wait to share some amazing shots of the working efoil. A big thank you to @Felixfoiler for the awesome remote!

Stay tuned for more updates! ![]()

![]()

![]()

If anyone has any questions about the things in the pictures below, feel free to ask.