When you have time, take a picture of the 12200 configurations with the blhelisuite.

very cool, nicely shaped board also.

some parts that could make a similar build quicker:

waterproof esc & motor full kit. in my experience the esc does not need cooling and everything works fine after a good few saltwater sessions

K parts pod SHOP - KPARTS WATERSPORTS

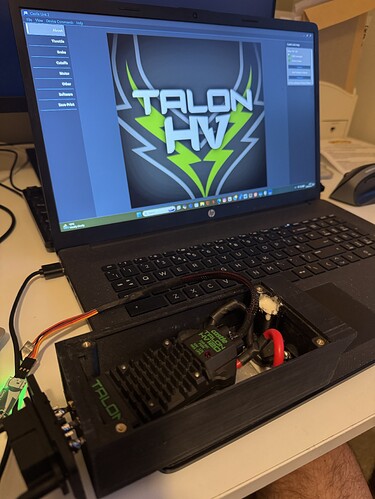

Really impressed with the performance so far of the Sequre 12200 esc but still nervous having read the number of esc failures on this forum, I’ll have a failure on a prefect wave day. So much so I decided to build a second esc and receiver unit and went with a Castle Creation Talon 120hv. Set it up and tweaked the settings with the castle link usb and for all its pretty heavy with heat sink case it feels and runs beautifully, hopefully get it on the water and tested this weekend.

Did you machine the ali end cap yourself ? Or did a local shop do it for you ?

Michael

I have access to a machine shop where I work so was able to machine it myself.

Originally I 3d printed the end cap which passed all my waterproof testing but over time it would start to deflect and bend out of shape, that was using PTEG-Cf but I’m sure there are better materials for that application.

Hey, I did a similar housing design for my foil assit. I wonder what did you used as a sealing bond between the 3D printed case (petg?) and the aluminium plate? (I mostly wonder because of the dilation difference that can occur here, I think epoxy can crack here)

Also, in the water, I guess that some condensation could be created on the aluminium plate due to the high temperature difference (sea vs box)

@Spearhunter the housing and cap are now both anodised aluminium. The seal in the cap is a 3mm thick silicone rubber gasket. With the cap secured / bolted down to the housing there is 18 to 20% compression of the seal. No issues with condensation

Thanks for the info ill have a look around for a machine shop locally, as my cad skills are not so great.

![]() Wrong product on the picture I guess…

Wrong product on the picture I guess…

Maybe you can get a discount from them for using your picture.

Haha yeah only thing FD in the advert is a FD 3 blade prop. A FD Cap as a freebie would have been ![]()

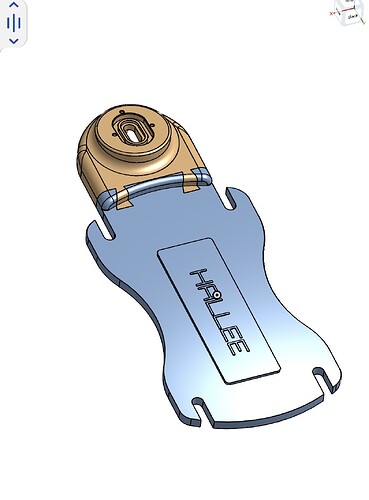

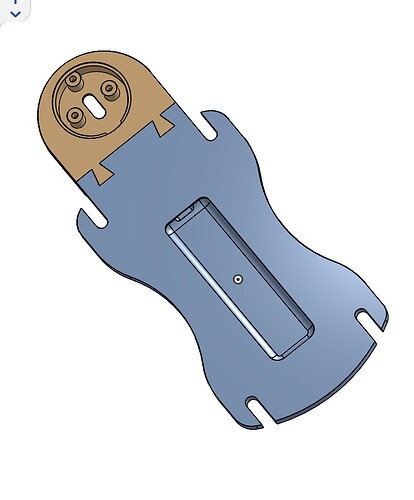

Having been using an aluminium mast with my foil

Assist that I I drilled and integrated the cables, i’m now wanting to try some of the integrated carbon masts. Only options for this is buy a carbon mast and start drilling (which scares me) or make my system fit the foildrive carbon masts - so came up with this adapter plate:

How are you liking the Castle Creation Talon 120hv? deciding if worth of the Sequre

how are you waterproofing that connection there at the baseplate?

great build! I like the amp jet approach with the battery slot, very nice ![]()

@patfoil I’ve pretty much just been using the Sequre 12200 esc all summer and it’s been flawless. Have fully tested the castle creation Talon and once set up also performs really well but it’s currently not getting used and is a spare for if the Sequre fails. The Talon is significantly heavier which is also a point to consider.