Carbon rods being epoxied in today with a mix of epoxy and chopped fiber for strength.

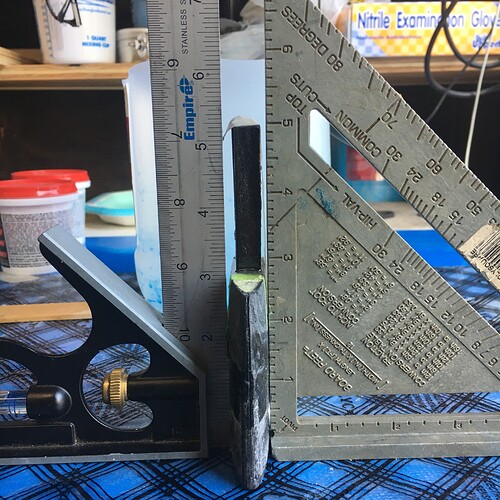

I’ll test fit the fuse and wing later and work on making a jig to keep the angles square while we epoxy in the other side.

Once that is set and glued up we can start building out the outer walls again.

Looking good! Someone stole one of my efoil remotes from our underground garage, and my tow rope!

You need to get in on this and let me and Ryan and Boogie Mike transplant your ESC and Remote.

Ok, so the patient survived and thrives.

Once I had the carbon rods set in, I was able to jig it up with a few levels and get it registered to the mast correctly. I epoxyed it in place and let it set as a first step.

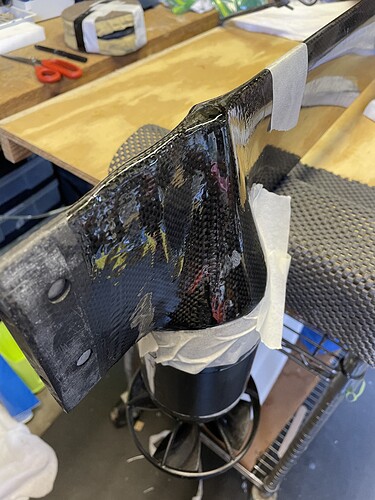

After that Ryan from LAFC came over, masked up, and got to work cutting 15 pieces of 6oz carbon in progressively narrower strips.

We used a wet out table to saturate but not over saturate them with resin. Then we laid then on the mast with the narrowest pieces filling in the deepest part of the repair.

Then we bagged it up with some Stretchelon and attached my reversed aquarium pump vacuum rig. You can see the peel ply (blue) the breather (white) and then check out how stretchy that bag is around the prop.

Once it came out it was mostly done. I did some sanding and cut off the excess at the back and then gave it a hot coat.

I didn’t like the bumps so last minute I sanded the hotcoat down and did another to get it nice and smooth. I’ll try to get a pop if of that this week. But it’s solid as a rock and back in the water!!

4 Likes