would you mind sharing the stl for the plug?

Thanks

How does it behave after some time, does the cable still hold its shape after some usage?

Asking cause it looks like you have coiled it up yourself ![]()

Thank you for sharing, will give it a try!

What a great setup - I love the simplicity! Would like to reproduce. What box have you used and how do you keep the ESC cool? ie does the heat sink stick out of the box?

Can you please share a photo of inside your box.

Have you tried a 6384? I’d be interested to know what its like compared to the 6374?

Thank you for sharing your information - much appreciated - thanks.

Yes I go to a bit of trouble to heatsink …

Here is a link to a similar setup done in an Explorer box

Bec and receiver in a small printed box on top of the aluminium extrusion.

I’ve used 6374 and 6384 Saite and Flipsky and also cheap unsealed 6384 Aliexpress. Prefer Saite 6374 followed by Ali 6384 120kv and also 6354 120kv. 6374 is absolutely heaps for me with twin Foil Drive props and 12S, I’m light, 66kg but use 46L board and in reasonable waves small foils down to Fireball 880 (600cm2). Flipsky are nice but heavy and I unscientifically think they use battery faster. I don’t bother waterproofing motors anymore, just install stainless bearings and soak in Corrosion x and spray with Corrosion X after every session. Interestingly 6354 120kv works fine with my downwind board if there is small wave to help get up.

The box is. Camdenboss CHDX8-321C fits XCross and 12S2P - battery in 8x3 block layout.

I designed a cable entry ‘thingy’ that eliminates the cable gland. Cable sheath is stripped and inserted then the petg printed piece is epoxy filled. It has 5 M3 heatserts that hold it to the box. Super low profile inside the box. Cable has a little extra strain relief by being threaded through the guards for the stainless steel over centre clamps that close the box

Outwardly simple but a lot of attention to detail (need to get a life ![]() ) This has done literally hundreds of sessions and been faultless.

) This has done literally hundreds of sessions and been faultless.

What a great setup! Thanks for sharing.

Do you think its possible to use 2 of the balancing wires (7.2v) instead of using a BEC?

Just priced up one of those camden boss boxes locally… yikes $546 just for the box. Might have to find an alternative.

What mast clamp do you use? I have a aliexpress 6384.

Box is like $60 Aussie dollars ![]() from Element 14

from Element 14

https://au.element14.com/camdenboss/chdx8-221c/enclosure-multipurpose-pc-grey/dp/2845604

Thanks. Ordered.

What did you use to attach the heatsink ? Not sure if thermal paste is strong enough for this application.

Any thoughts not using a BEC (powering RX directly from balancing wires)?

I use Kafuter thermally conductive silicone between esc and heatsink

I just found this on AliExpress: AU$19.58 | Kafuter 80g k-5204k LED thermal conductive silicone CPU bonding adhesive quick-drying thermal silica curable coefficient 1.6

https://a.aliexpress.com/_mOvsGVf

To bond the heatsink to the outside of the box I use

https://www.fixtech.com/en-US/products/fix15-multipurpose-adhesive-sealant

Making sure to roughen both surfaces and clean thoroughly then ‘butter’ the adhesive to both faces before clamping together.

Thanks again for the info.

What battery layout have you used to fit into the box? I will start making these while I wait for the box to arrive.

I want to use 2 x 6S in series… as I already have 2 6S balancing chargers (and these are only $30 each).

Layout is 8 x 3 in a square block. I doubt you will fit two individual packs in the box. It’s a tight fit

I have put 2*6s2p in that box.

But it is a pain to setup every time you take the batteries out.

If you want to use it on a backpack, why not get the bigger box? There is really no downside to it in that situation and far easier to work with.

CHDX8-225C 220mmx170mnx110mm

For some reason that model is also really cheap here, at 20,40 EUR

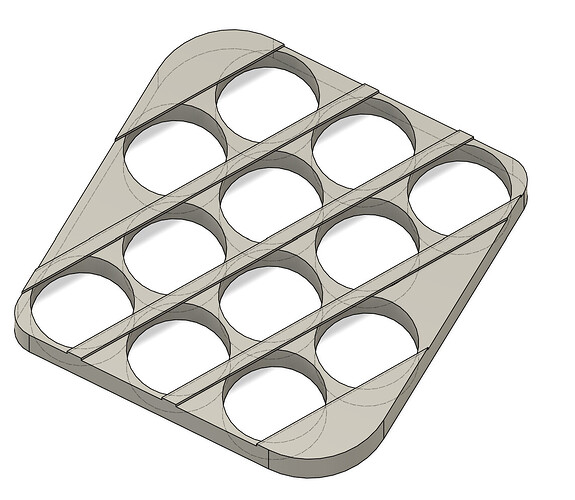

If you really want to do it, this is the layout I used.

Size is 82mmx86mm

If we are on the subject of boxes and heatsinks, a bit of helpful information for anyone interested.

There are three brands that have good quality seals, Camdenboss, Bud Industries and Polycase. I had a size I wanted, then checked all three brands and went with a Bud Industries.

I used a Flipsky 75100 because it has a flat heatsink and I could just cut a hole and stick it to a heatsink attached on the outside. I used a 75200 heatsink which I bolted on with a gasket around the edge.

I used a thermal conductive adhesive sheet to attach the ESC to the heatsink. The 3M model of thermal adhesive was a nightmare and not put on evenly, but it works well. The model of conductive squares I used previously were easy but I couldn’t find them.

The thermal silicone sounds much better, and I’ll use that if there is a next time.

What mast clamp have you used? I’ll buy a FD prop - which do you recomment 2 or 3 blade?

Thanks.

I use home made mast clamp, have designed many for all different masts. I use two blade prop.

This Axis internal cable worked really well

That looks impressiv. Do you have the stl. for the “thingy” and for the grey cableholders on the ouitside of the box? Would be nice…

Here you go

Did you cut off the little lumps/upstand things in the bottom of the box? If so - how?

Yep, cut them off with cut off wheel in Dremel then sanded them with flat sanding disc on Dremel. The ones in the corners then have a hole going right through which needs to be filled with epoxy. I slightly countersink both side of the through holes to give the epoxy a better footprint.

From memory I also used a small round carbide burr in the Dremel to clean up the corner ones before sanding.