Pretinned the copper bar and put solder flux on the nickel strip. Then I clamped the two together using three binder clips and heated it up with a torch. The lugs were soldered in the same way. Seemed to worked well, besides the discoloration.

Got a new fuse for the kweld and got started spot welding again but damn it takes forever waiting for it to cool down after every three-four welds.

2A pico fuses soldered to the bottom of each nickel strips and led through holes in the cell holder.

Here’s my kWeld set up - I’ve put some ceramic tubes around the electrodes for insulation. Works pretty good, but I think I’ll just attach a second set of electrodes so one can be cooling while I use the other.

I got the idea from Jatem - My one was similar, but the bottom mandrel was the full length of the strips and the former on the top was made to rub along the full length, rather than down.

Started working on the board. Motor mounts are printed in petg and feels very solid bolted to the board. Designed some custom holders for the rubber straps that mounts through the board. Also verified that it actually floats.

Nice design.

I went through a few body boards before figuring out the balance points, just as well they are cheap!

From my experience the motor needs to be further back - the prop approx 50mm inboard from rear of the board.

The tow point 150mm or so behind the prop, and at water level.

The pelican case needs to be as far forward as possible, and slightly to the left. A cut block of foam on the front will prevent nose diving.

The moment of inertia is too low like you have it and will cause the board to fish tail when you go fast. Having the weight spread out seems to prevent this.

Thanks for some great tips @Strongarm! As you can see I decided to move the motor and prop forward (to decrease the leverage between prop and aft of the board). What negative side effects can I expect from having the motor this far forward?

Because the moment of inertia is small the board will fish tail when going faster.

The board also wants to nose up when taking off, having the weight at the front helps counter that.

The torque from the prop wants to flip the board clockwise, that’s why front left for the battery pack is best.

Give it a go, it’s easy to make adjustments! Here’s one of my body boards that I had to move the motor back a bit.

I’m not sure I understand what fish-tailing is. Would you care to enlighten me?

Going from side to side (swaying)

Tow line is attached to the upper mast plate and runs through a carbon tube internally to the back of the board. The carbon tube runs inside an electric pvc tube and is easily removed for transportation. The fitting at the back is fastened with gorilla glue and two 3d-printed screws.

Very sleek ! However why a rigid tube outside the board footprint ?

How did ou achieve that ? Did you drill a hole in the board thickness from mast plate holes to the board back ?

I’m just copying what other people have done.  I’ll probably shorten it but it’s cheaper to chop off some more instead of having to buy a new carbon tube.

I’ll probably shorten it but it’s cheaper to chop off some more instead of having to buy a new carbon tube.

I drilled through the board. The internal parts look like this:

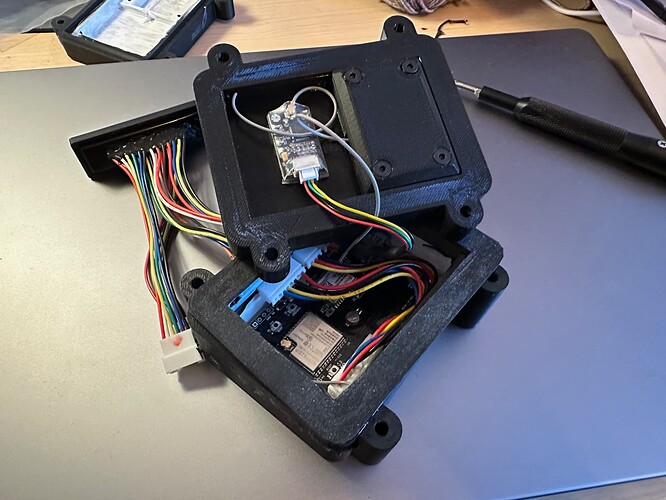

Splash-proof case for receiver and the VESC BLE module. GPS antenna is mounted in the lid with a cover and four small bolts.

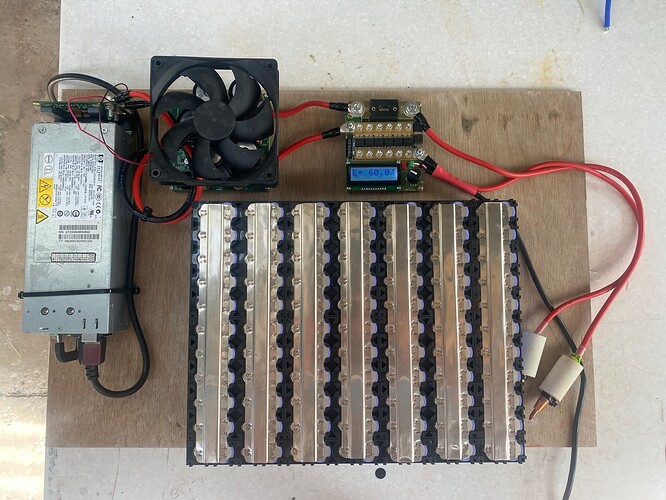

Battery case mostly done. Still have to hook up the temperature sensor to the VESC but haven’t found any information about which pin to use. Not necessary so I’ll probably do a test run on the water tomorrow.

Great success! Remote, vesc and motor worked, no tendency to lift the nose or flipping on the side. It did submarine a few times when going slow but the big problem was that it started oscillating left and right when going fast and straight (I think this is what @Strongarm predicted). Will try some fins at the back tomorrow and see if that helps.

No 3D-printer at the summer house so I made two temporary wooden fins. Worked like a charm. Also moved the battery case back 10 cm which solved the submarining.

Nice!

Noticed your motorcable connectors there. Looks nice to be able to disconnect the battery box from the board. Where did you found those?