Not many because from his statistics he hasn’t really been to the site since. I asked for the dimensions of the enclosure, but got no response.

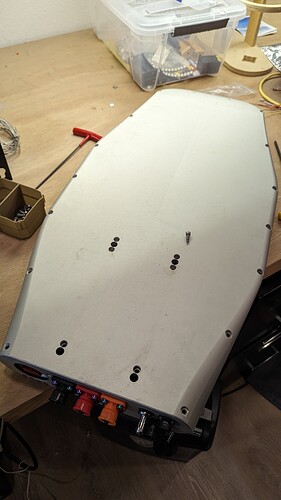

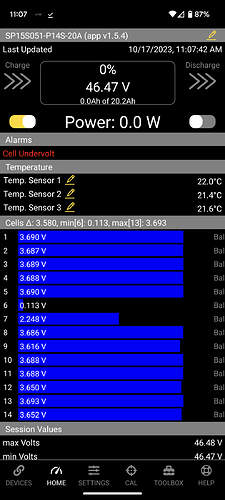

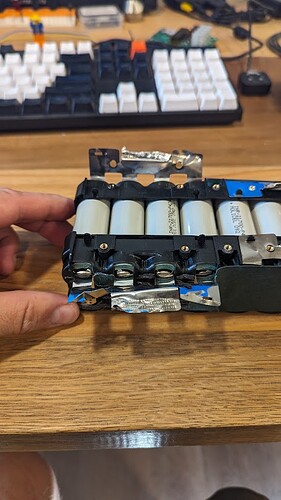

I am checking our a vortex for a buddy since they stopped responding to warrenty emails. wasn’t able to charge, but discharge worked OK. I was able to use the overkill solar app to recognize the BMS bluetooth. Looks like one cell is shot… Double checking now to make sure there isn’t a loose wire.

Since I got it cracked open on my desk, let me know if anyone else has questions…

What the thickness of the walls, base and top of the housing?

Wow I though the top/bottom would be at least 5mm, but I guess the rely on the bolts running through and compressing the enclosure. Would be interesting to see if it survives a foil crash.

I thought it was CNCed but it looks like injection molded aluminium. Can you confirm ?

That’s a lot of weight for an enclosure, seems like a suboptimised solution, all that just to be able to use your existing board?

Yes it is CNCed. There are tooling marks I can see.

Yeah pretty much that. I think they were trying to target people that that already had boards (and foils?) and the preorder price was only 3899 which is a pretty decent deal at the time.

We had 3 guys around here with one. It is nice that you could go to the beach to wingfoil, the wind dies, and slap it on that board and not have to bring much extra gear.

Same problem as with the rifle case: how thin can be the enveloppe when top and bottom skins are locked to one another … both skins work together…

It’s actually pretty light enclosure-wise.

±2.7kg for a sealed enclosure, 6kg for a board and you’re under any commercial efoil. Most commercial boards struggle to get under 10kg just for the boards.

When pwrfoil did an enclosure like this I thought it was ugly as anything, but weirdly enough my use case of boards and foiling has changed now and I’d happily use a solution like this.

Interesting:

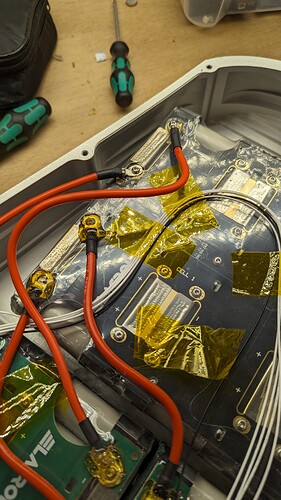

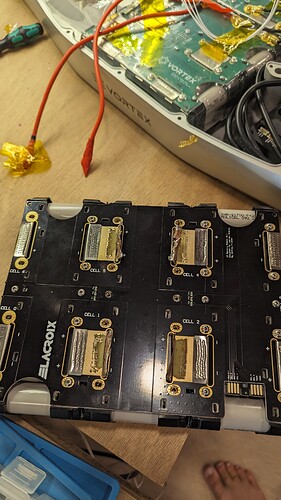

A lot going on in there. The 3 power connections to the VESC and external BMS makes it look more spaghetti like than a lot of even DIY builds. It does mean that fault finding like Bryce is doing is a lot easier though.

I get quite a bit of joy seeing off the shelf components being used in commercial products like this - it make sense, no point in reinventing speed controllers or connectors for low volume products.

It’s interesting that they used a single xt90 for the battery connector though. I would have gone with 2 or an as150

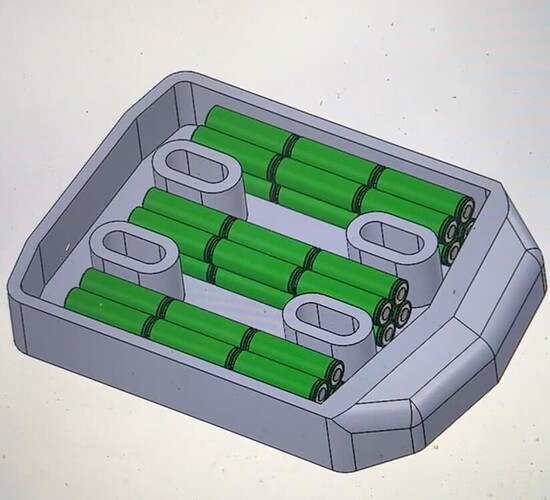

This has nothing to do with a vortex. The design for bottom of the board units existed long before the vortex was designed!