I’m starting my tow build, been thinking about it for some time but didn’t find the time really ![]()

Thanks @Jesserosco, @rttn, @Etiennebzh, @ludwig_bre and @jenz for the build info and help so far!

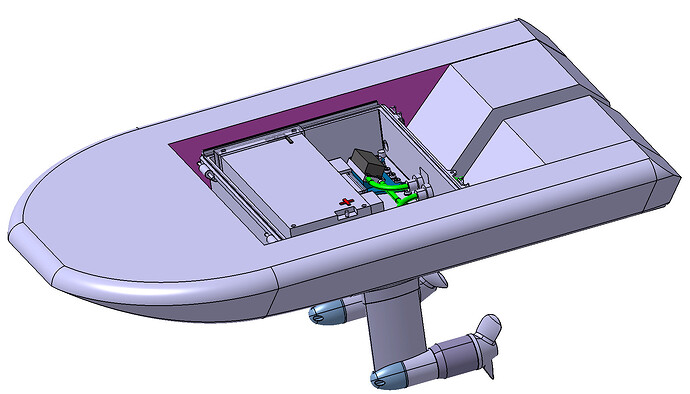

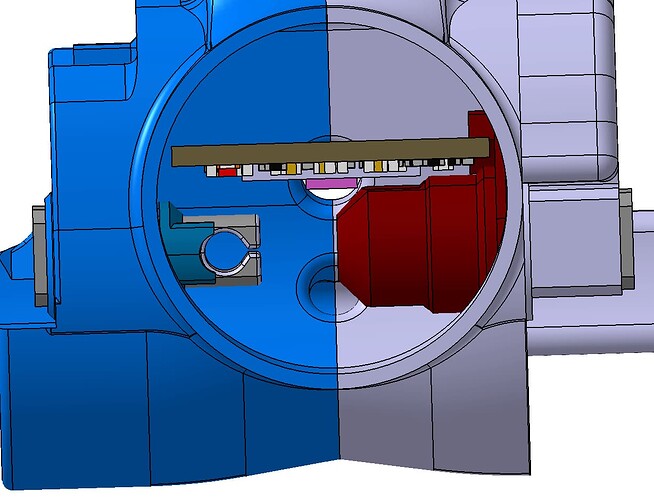

CAD status:

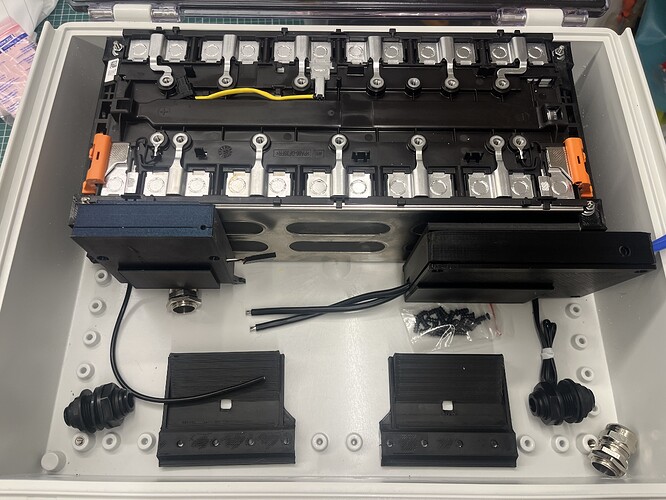

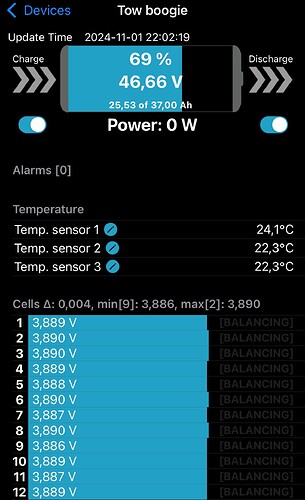

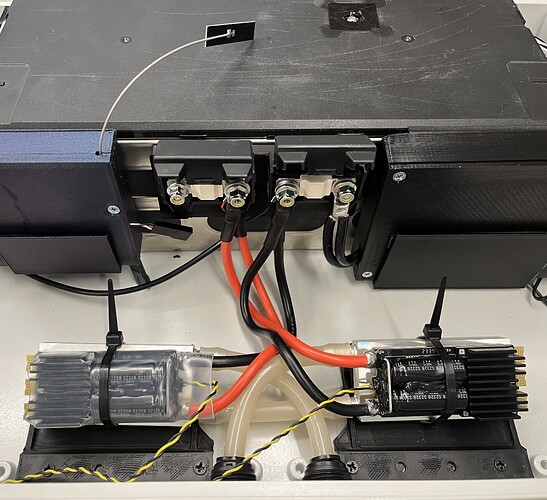

It will be a differential steering tow with dual (cheapest ) 6384 motors and water cooled x-cross 120A ESC:s. I bought the ESCs a long time ago, with the recent x-cross failures they seem pretty sketchy, but i hope they’ll last some months at least.

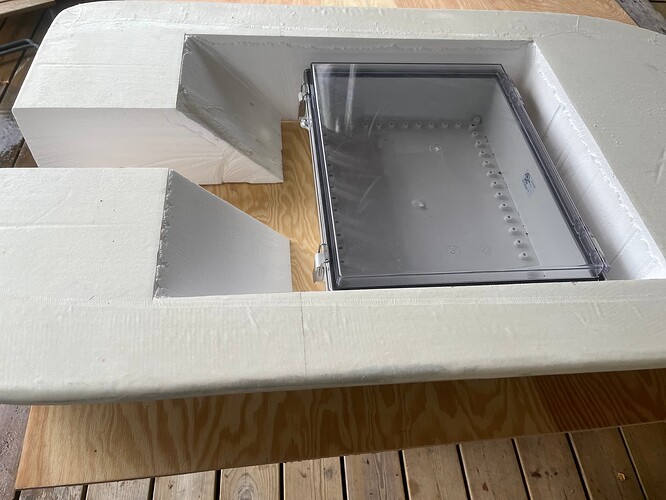

For the board I adapted a board plug i had already, I originally made the plug for an efoil but didn’t like the shape:

I’m aiming for a low center of gravity and to be able to move the motors freely, so the bottom of the board is plywood, overlayed with some cheap UD carbon.

I cut holes for the motor wires and designed a passive water cooling intake:

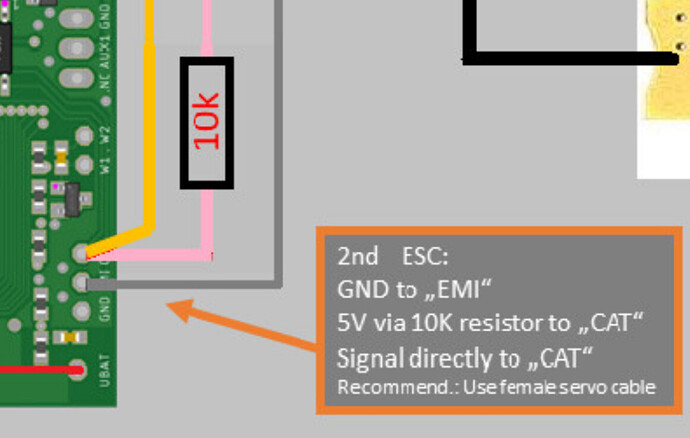

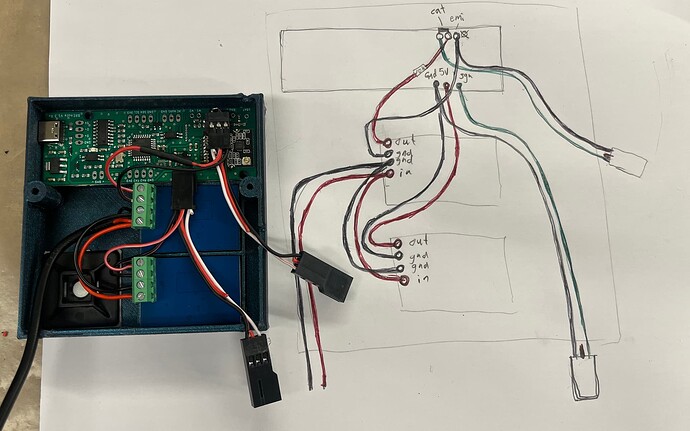

I also started on electronics ![]() I uploaded a connection diagram here: Bremote connection for dual steering ESC + BEC - #4 by Larsb

I uploaded a connection diagram here: Bremote connection for dual steering ESC + BEC - #4 by Larsb

As there are only two holes used on the PCB and three pins on a servo connector I’m cutting one header pin off at the bottom and bridging the pin header for the dual steering connector on the PCB here:

I wish i had the skill to change the PCB layout to make it a dual steering PCB without mods, any chances of this happening, @ludwig_bre?

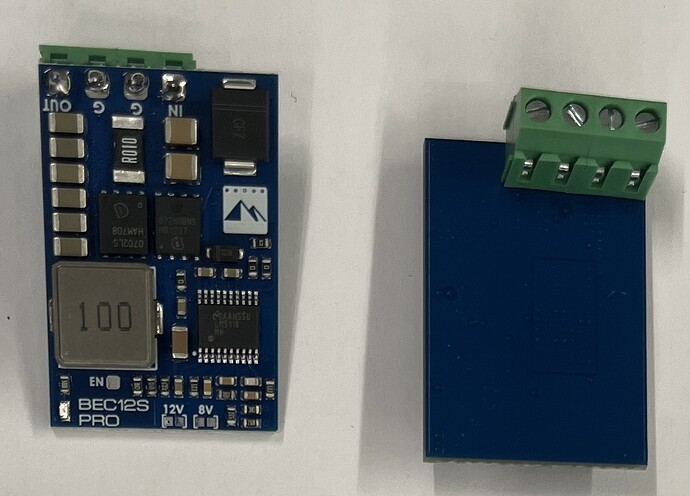

I soldered terminal blocks to the BECs to get a more clean and robust connection:

I also designed and printed a custom box for the bremote Rx and the two mateksys 12s pro BECs:

For the connections i simply used two short Y-servo cables, they were really cheap so wasn’t worth it to buy a servo connector kit.

It feels like this was the complicated part of the build, maybe except for building the Bremote LR, i hope that the rest goes easy ![]()