Nice, weight adds up but the maytech motor has been reported as being poor quality and too weak. Hope it works for you.

Today was a Real World test of dw with the assist. 30+kt winds against river current, nice short bumps 0.4-0.5 meters. Good feeling on the png1300.

Result, popped a mosfet on the already repaired 60100hp and finished the session by rock start DW ![]()

![]()

Box on deck

Pros:

You Can get signal underwater by having the remote in contact.

Signal IS very good overall

You get visual if any water Comes in

Cons:

Feet placement, I could barely pump the board

Can not paddle the board, box in the way.

Weight not centered (Can be fixed by having the box between both feets as suggested)

Power was barely enough to get started when not being carefull due to the very choppy water. With right timing with a bump, it was very easy.

The différence between the bare board and the assist equiped board was huuuge. Weight centering is probably a good chunk of that.

Second thing I re-learned is an assist could get you in a Bad situation if it fails far from shore, on a small board.

I had a life jacket just in case, but not being able to paddle is a Big risk.

Video :

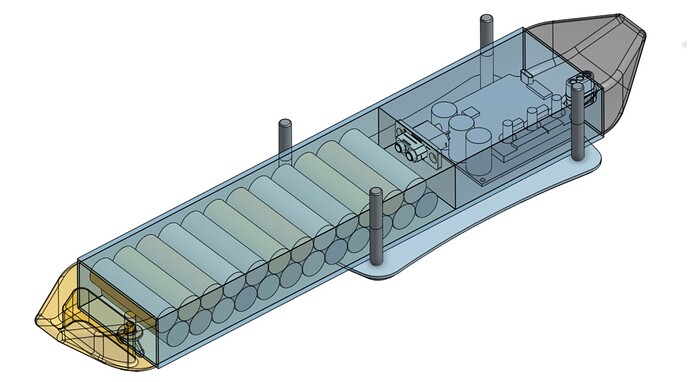

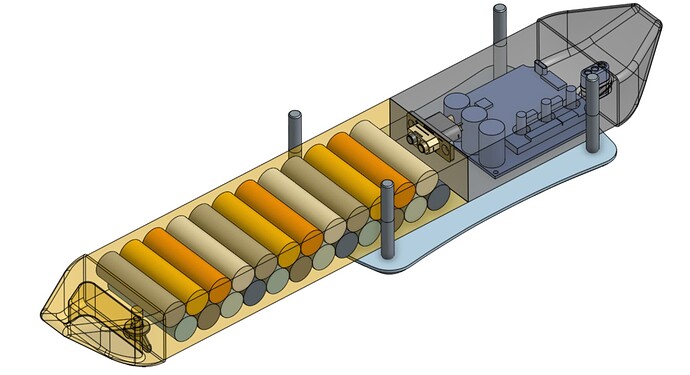

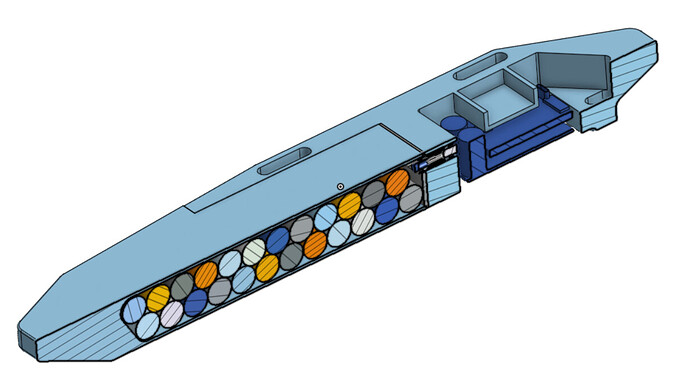

Making progress, with another concept, using a 80x40mm tube, and two cast parts that would slide in from each side. It only fits 12S2P 18650.

With this setup, the tube is only 2mm thick, so the cast part has to hold some constraints.

So maybe needs a extra part to hold the force, such as this that could be CNC or printed and glued to the tube :

Such a setup could really fulfill the “light” goal, for a assist only type of build, not really designed for efoil.

A few layers of carbon would do the trick, that’s what i would try first, minimal weight and a real simple lamination job.

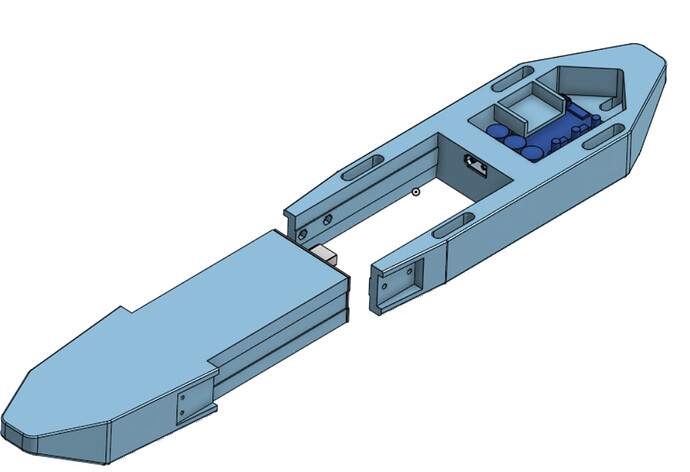

getting somewhere I like with the design. maybe first prints this weekend

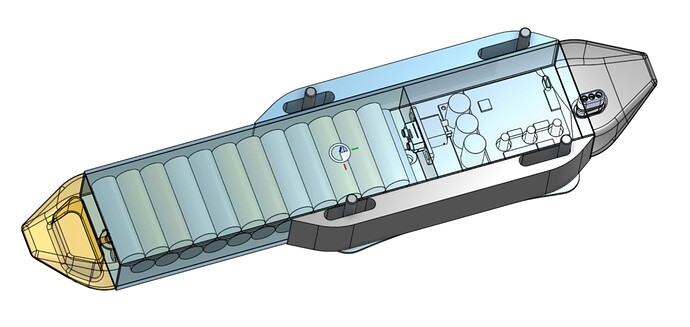

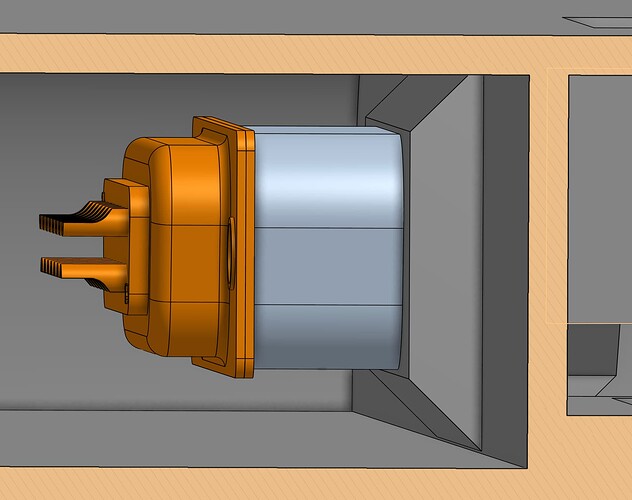

The 84100 has arrived, I will still use a maytech RX, as I fear BT only will be too weak, the RX will go on the little tray.

I received the waterproof XT90, and will use POGO magnetic connectors for balance with a custom connector (no internal BMS)

Ordered this for casting :

Amazon.fr

Lock I ordered and received those, they will go on the front to lock out the battery pack.

https://www.amazon.fr/-/en/dp/B0CJM71T1C?ref=ppx_yo2ov_dt_b_fed_asin_title

For cells, I have 30Q and P28 available, probably go with 30Q first as they are refurbish/salvage cells and not a big deal if they die from water or other cause ![]()

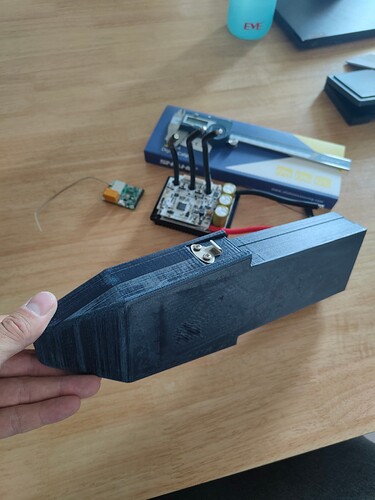

The back part is thicker to make sure the battery can slide in an out with the foil installed

Glad to have a big printer

Great! I didn’t know, thought even to make one myself.

What is the advantage vs regular db connector?

btw found 20-pin magnetic

I have received these, they are small, feel good quality, have a spring and cheap.

Thanks.

Probably good stuff, other than thermal conductivity.

How do you cool the esc?

The locks seems very similar to the amazon ones, only cheaper as usual ![]()

The connector is nice!

Too bad I need 13 pins, but I will order some anyway, thanks for the share. I had 4 pins available and was about to use a few…

EDIT found 13 pins available, thanks for the heads up!

https://fr.aliexpress.com/item/1005007438592794.html?spm=a2g0o.cart.0.0.43fd378dq7QrUq&mp=1&gatewayAdapt=glo2fra

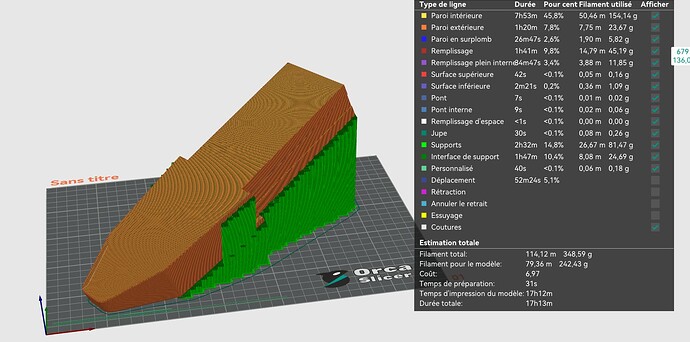

First print done, after a failed attempt last night (overhang too extreme)

PETG-CF

Second part is printing, testing again with PA6-CF (insipired by @hangloose )

If that fails it will also be PETG-CF.

The esc bottom is not cast, it is toutching the mast base plate. With a CF mast, it will not dissipate a lot. But my own and other people tests of the 84100 show that that should not be a problem, wether light efoil or assist.

So what you see as an advantage of this magnetic connector?

Do you print a cap with silicon to waterproof it?

In my over the top box battery design there is also a balance connector. I decided to use db connector . BTW are you aware of G20 connector ?

You can try ASA or ASA-CF (I didn’t yet). Advantage of ABS or ASA is 20% lower height.

I would not print anything with Nylon in water because it seems to me that it will absorb water. Also the creep of particular nylons is not good.

The G20 would be way to big I guess. The battery will be held on the fixed part where the controller is mounted, it give me a flat surface, I will make some kind of seal there, and apply grease on the contacts. The locks will keep the seal compressed and hopefully water out of the POGO.

Yes, for me as well the G20 was too big.

Me too compressing the connector cap against the esc wall. Just need some kind of cap for battery transport.

I will switch to pogo connector as it is slimmer and contacts are easily accessibe for cleanup.

You will use the one with ears or without?

Cap could be just the cut male part . It will be held with it’s magnets

Or the cap can be screwed to the battery case.

Where did you get Cad model? Can you share it? Thanks

The 3D model above is of a DB connector. The magnetic connector model is still in progress and will be added here once completed.

I don’t recommend ASA, poor interlayer adhesion. PETG are best (or ABS-PC if you need low weight). I wouldn’t print PA6 either, it will become soft and lose its shape very quickly, but you can try PA12CF.

Indeed I saw as well bad layer adhesion with ASA even without fan.

PETG no fan I get the strongest layer adhesion.

What abs-pc brings to the table?

Do you mean what is the adhesion to the bed? Excellent if the bed heats up to 110 degrees.

I want to belive.

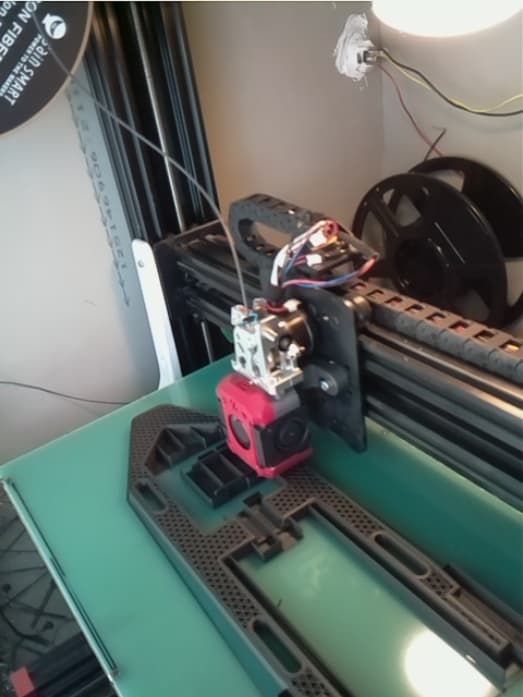

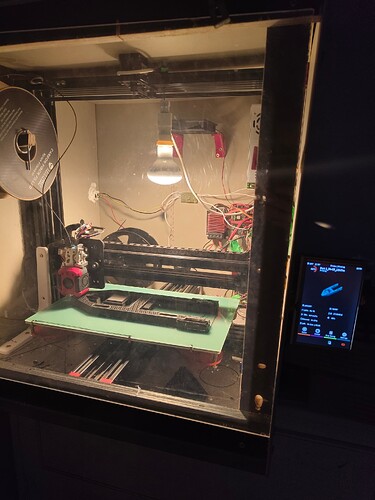

Just a post for details on my homeless printer.

Taken back from the grave last year

Lives on my balcony

8 year old tevo black widow 350x250x250 usable build volume

Burnt temp reading traces and IOS on the original motherboard, replaced by jumper wires and salvaging other inputs.

Running original steppers, motors, belts, rollers

Replaced all cable guide wiring twice due to broken wires from back and forth movement of X

Klipper on Pi zero, with 5 inch klipperscreen, webcam

Input shaping (5k acc, 300mm/min print speed and 750 travel moves) travel speeds and ACC irrelevant for bigger prints anyway…

Hgx Lite extruder

Dragon burner toolhead, with Bambu style hot end

Garolite/G10 bed plate (perfect for PETG and PA)

DIY enclosure, with 100w heater bulb and fan for air circulation

Jankiest wiring ever seen

Materials :

Personally have great experience with ASA, I printed a full pump foil board from it, and the layer adhesion was excellent. I printed in enclosed printers/heater chamber. ASA -AF is very nice also, but harder to print. Overture ASA is decent, but formfutura appolox is the real deal.

I tested ABS-PC but did not get strong results and a lot of warpage.

Petg-cf is a recent revelation, I tried it after being disappointed with pa6-cf

The latest run of blades I did in petg-cf are close to perfect, all stl aretefacts are visibe in the final print. With a severe overhang and no support, that is definitely a win. I use flashforge brand, zero warping in my setup. Never had a enjoyable experience with pure petg, even higher end stuff (hdglass from formfutura, 3kg roll)

My work printers are exclusively chewing through 8kg rolls Of formfutura apolox / appolox-AF now, but for hobby stuff it is a bit pricy.

My test for layer adhesion - I print one line thick wall and try to separate the lines. With petg I couldn’t. With ASA I could.

I set pretty high temperature on both, no fan.

Maybe the brand of ASA makes a difference.

Good for you that you like to tinker with the printer.

I use now Qidi xplus3, but next printer will be ratrig vcore4 500 idex because having great idex plus other greatness, just have to save 2 grand.

I am Always eying custom builds, voron kits and others, but in the end the Time/cost ratio between fixing what I have and a New printer build goes toward the Homeless printer, also a little reluctant to just throw away the goods just because a New and fancier printer is available. Klipper really changes the game for those old printers.

The print clogged 11 hours into the 15 hour print. I could resume it but it is quite weak in the re-start Line.

Probably usable with a loaded epoxy coat.

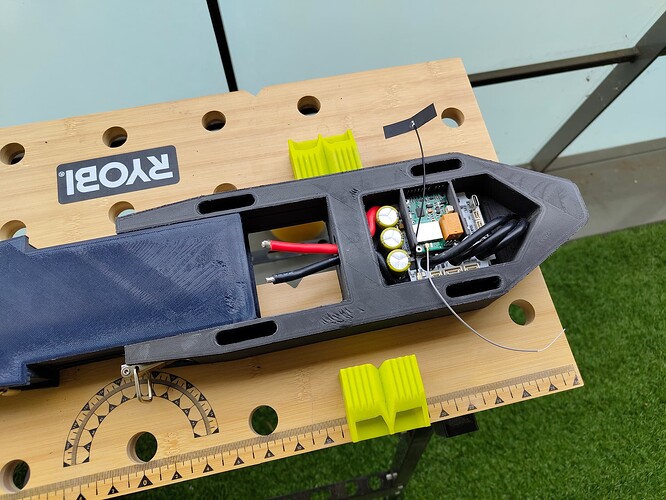

Quite happy about how it fits so far, the controller home was slightly too tight, but other than that all wires and éléments fit perfect, no need to add any length to the cables of the vesc, they Can be directly soldered to the plugs.

Few minor design fails upon closer inspection, that will justify a reprint :

- XT90 is on the wrong side, + and - are inverted compared to the vesc wires

- XT90 will be close to impossible to solder and install, I have to rework the opening to make is easy to insert from the top

- clamps are hard to acces, need to make a pocket for finger clearance

Some open questions : -

- Should I make the controller base as wide as the mast plate for best rigidity, or keep as it is for less drag when in the water

- Where to locate antennas for best signals