Same thing happened to me. Bad spring quality

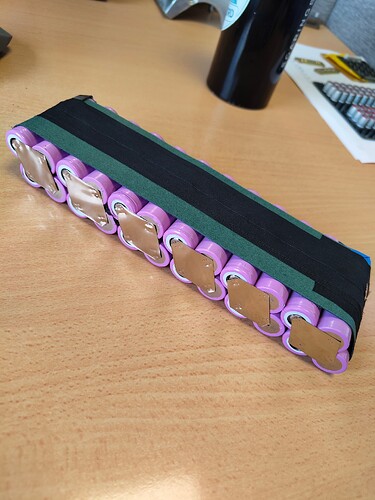

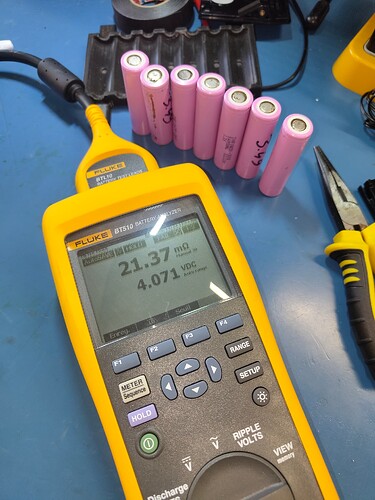

Prepared another pack from matched cells. Selected cells are below 16 mohm while rejected cells are 17 to 30 mohm. P45B are 8 mohm and P50B 6mohm.

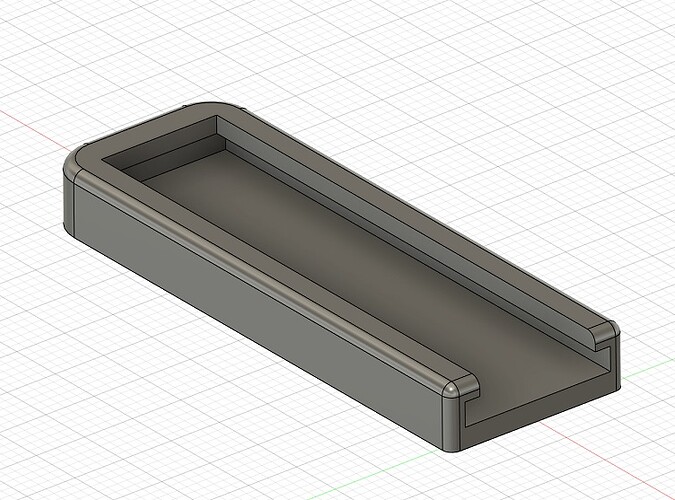

Printing the top casting version of the battery tonight in order to ride it sunday ![]()

What are you limiting your battery current to?

40A with the 30Q cells

Foiling needs 15-20A

Where did you find P50B if it is not available yet…

We have some direct connections ![]()

Inspected my first pack by removing the gel over the balance wires, it is all over the place.

From 2.4 to 3.4v per cell.

Not worth the risk/time, I will scrap it. Was expected, due to the lack of cell sorting, and old salvage cells. Got 3 rides and design validation out of it ![]()

So probably can get 10-20% more run time with the sorted 30Q pack.

Due to the lead time on the pogo, I will cast a balancer board into my second pack.

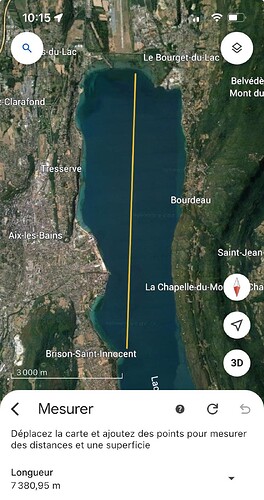

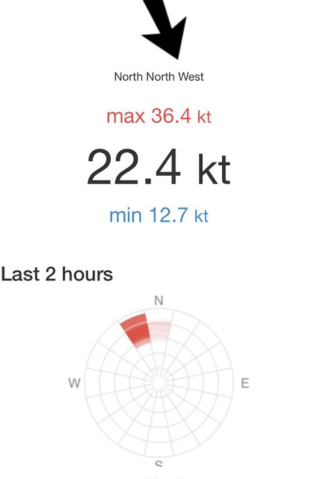

Big lake downwind planned Sunday ![]()

Not enough Space to fit the balancer I had to change plans.

I will remove the foam from inside the battery case, and cast the connector in gel. When I will receive the pogo, I will wire it UP and cast it also.

Used 160gr of epoxy for this top casting for future reference.

The plan is set ![]() hopefully two runs.

hopefully two runs.

It should be slightly less windy tomorrow, there is a risk of being overfoiled quickly on the png1300.

I have received my 1201 front wing but not the matching fuse ![]()

I had mounted the maytech for this run = Big mistake.

I only managed a few starts with close to full battery, and used way too much battery for failed attempts. After 30 minutes of trying, the battery was empty and all I could do was slowly motor towards shore, AT about 1/4 of the full run. Also had 5-10 minutes of swapping blades out in the water as two broke (leash in the prop?). Do not loose the multi tool, I repeat, do not loose the multi tool.

Quite a bummer. Let’s see run 2 with the 6384.

I think I was mislead from last test of the maytech 6374 where I started with full battery and only e-foil/pumped rest of the battery.

The signal quality IS also a Big issue for efficiency, as a lot of sucessfull liftoff are tossed away due to cutouts when transition to standing position.

Maybe it makes sense to try an external antenna? Mine works perfectly with the carbon board.

Yes, but how to intsall it now that the rx plug IS cast into epoxy ![]() Can the antenna be soldered ?

Can the antenna be soldered ?

Replacing blades out in the water…wow I imagine

I hate my leash which wrapes around the foil…and I feel how it is dragged behind in the water. Didn’t think it can hurt the propeller… will try the spiral leash again. With the spiral I hate that it put itself behind my rear feet and I feel it.

I had the leash on my hip pack, so I dont know how I could do much better.

Had redemption on the second run with 6384, 3km mostly on foil. But it was interrupted again due to a broken blade.

It’s very simple. Solder two antennas together, use the thinnest heat shrink. Press the antenna with the case. But you can also try to simply attach it to the side of the case with waterproof tape. Works in any orientation

At the bow of the board, I installed this antenna holder using double-sided tape.

Great progress ![]()

Can i ask what you eventually used to pott your batteries? Ive already had rust on one pack and had to dispose of it.

Read allot of discussion on what and how to to it

Was thinking initially use:

Liquid electrical tape or plasti dip spray

https://www.plastidip.net.au/

Or a heat conducting silicone

Both flexible and allow for expansion?

Bit concerned about extra weight for the silicon fill.

Raytech magic gel, alao and option

https://au.element14.com/raytech/magic-gel-300/

Maybe all encapsulated in hard epoxy?

For impact resistance

To save weight and lower material cost for potting. With the ideas listed above would also use a lightweight high temp low density foam to seal between the battery cavity ends, leaving an air void in between cells.

There are fireproof foams used in building construction that may be suitable?

Other oprion is to use exoxy with microballon paste to fill to void ends.

Then pott everything?

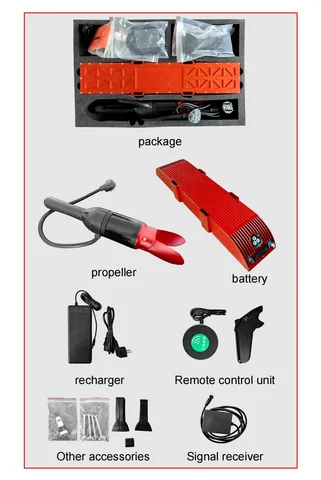

Alibaba Foil Drive gen 2 copy

Around $2K Aud. Looks like 27100 13S3P?

The battery / Esc housing might be usefull for a diy build project?

Heat shrink and then seal the ends with something.

Ordered the coax antenna cable for the extension. I have self adhesive antennas available, I will try that. Good signal would make a huge difference in ease of use and efficiency!