6374

The issue is 140kv vs 120kv for my 6384, and stator is 10mm less. Will check with max amps

I found the maytech hit a point where its just couldnt take anymore current no matter how much my speed controller could let it have. It was just maxed and couldnt do anything more…

Actually having the same issue with Flipsky 6374. The Sequre 12200 is now at its max but the motor keeps stalling around 30-40% throttle depending on the SOC and Propeller choice. Probably with a bigger more efficient board (30 liter at the moment) it could work but that’s not my intention with an assist build.

Next time I’m going with a 6384 again.

@Joshi I will try to increase amps and report back, but on the worst case I also ordered a new 6384, in case the 6374 maytech is still problematic.

Anyone has a 3D model of flycolor 160A and sequire 12200 esc?

I want to check if those would fit the system, before writing documentation and releasing the files.

I have run the flipsky 6374 all the way to 4kw with a vesc. So id take a look at the esc. It definitely shouldnt stall at 40%.

Same topic with a vesc. Also stalling around 33% throttle and maxing out the amperage.

In my mind it’s just an issue of required torque vs vessel speed.

If you have a bigger volume board getting on plane already at 30% throttle sure there is less torque required and you can accelerate easily above the critical point. In my case there ist just to mich drag, low speed, high torque required and the motor stalls.

Otherwise a smaller prop could do the trick by reducing required torque and allowing the motor to spin up higher putting out more power as a result.

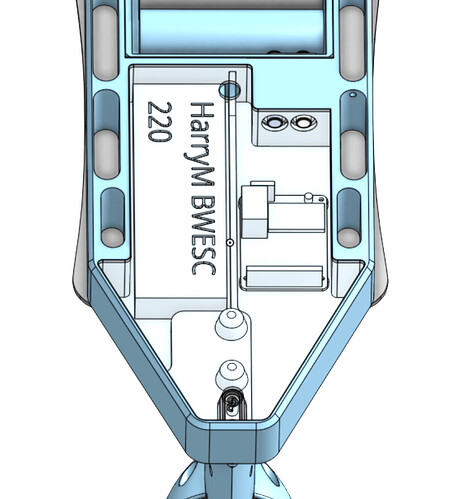

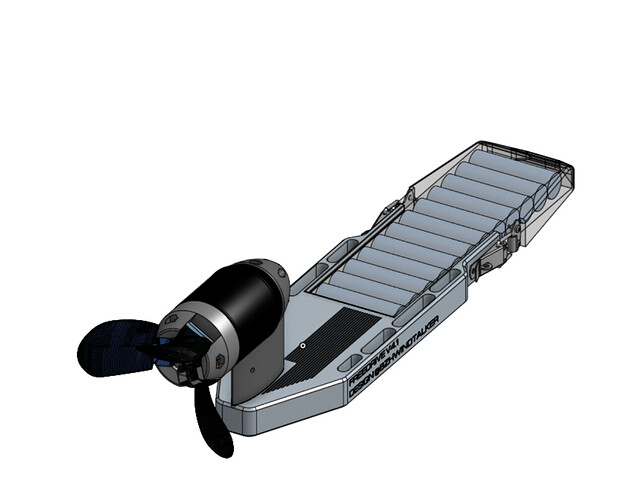

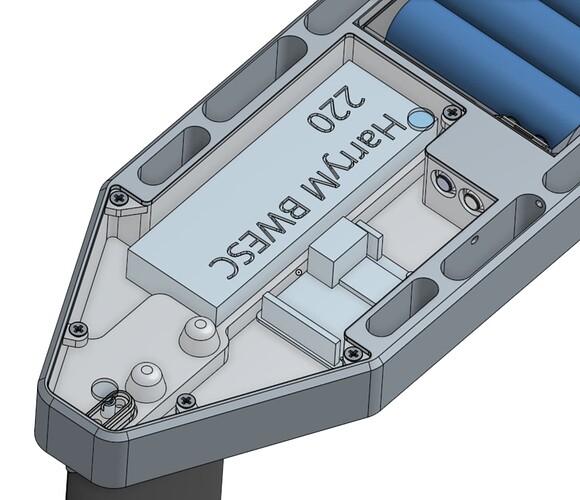

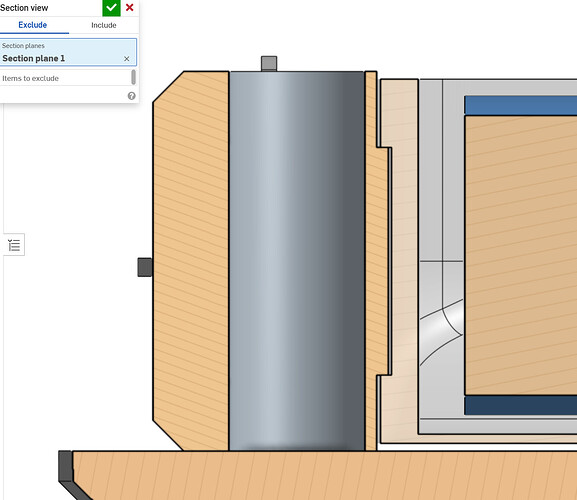

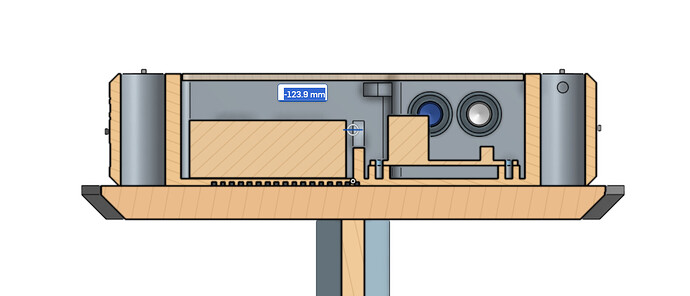

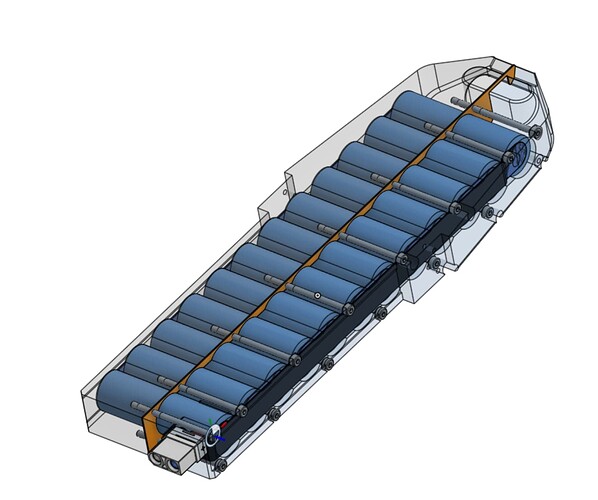

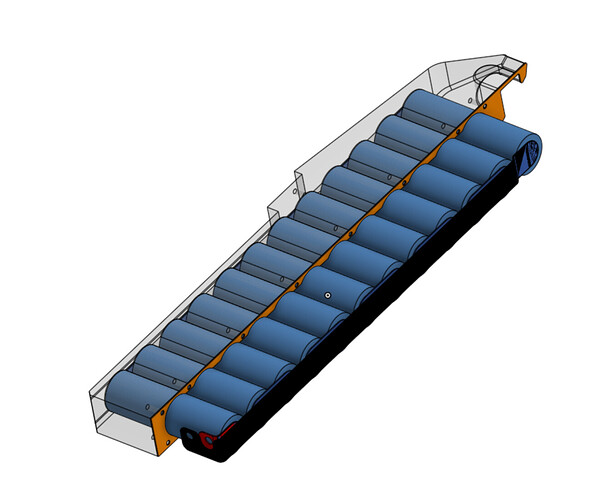

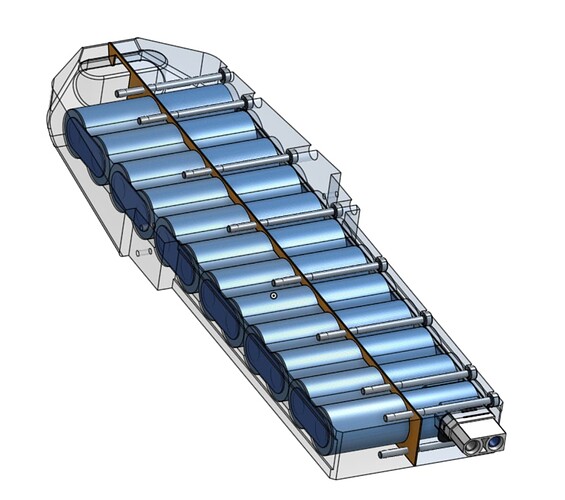

Some cad updates on a calm sunday.

Reworked CAD models to get it ready for sharing.

Added some small external ribs for cooling, not that it would be needed, but it looks better.

Added bosses for the cover, with 5x M3 screws (hey are below the TPU pad, no risk of board scratch)

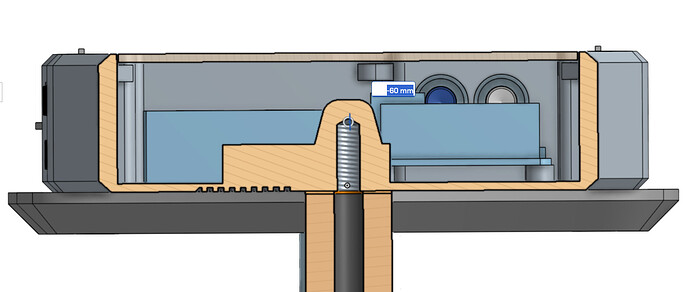

Cut views

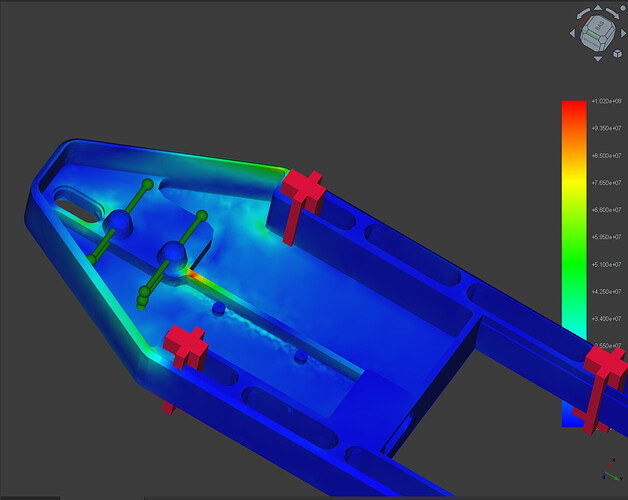

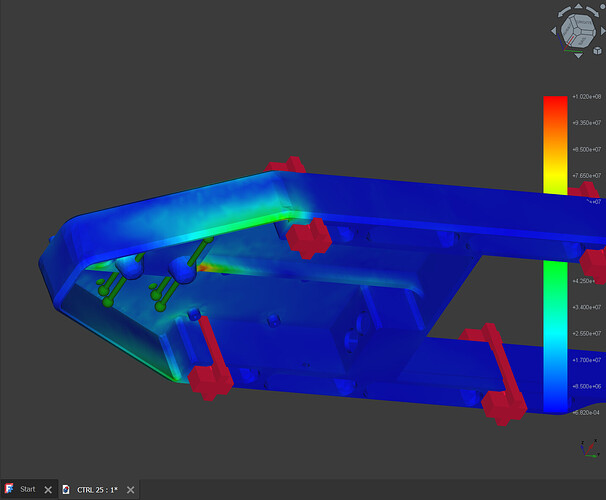

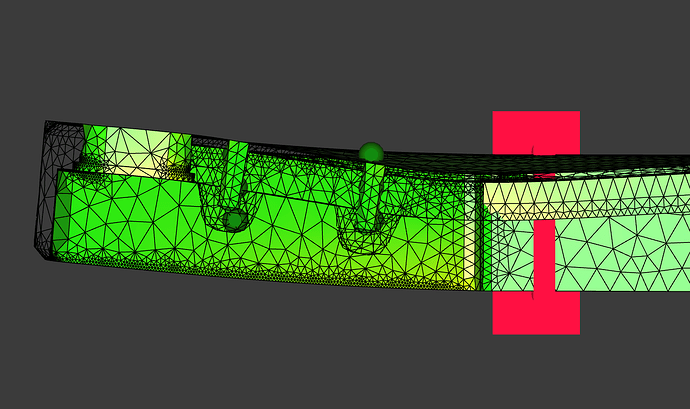

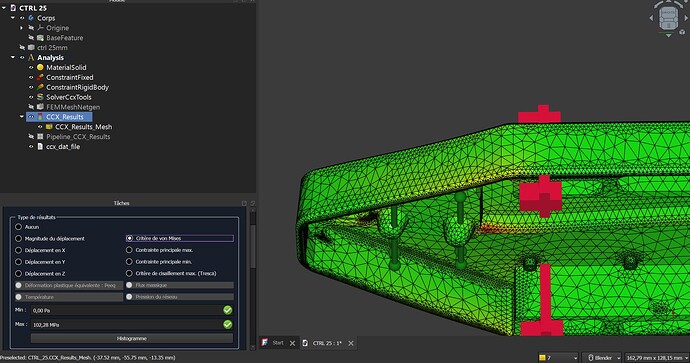

Some calculations in freecad to check for weak spots @50kgf motor thrust

Max 115 MPA on the top of the internal rib, it is doing its job but could be higher. Fatigue strength for most alus is around 80 MPA to be on the safe side.

TODO :

- add the correct screws FHC M8x55 and pod screws to the model for future reference

- rework the rib to spread the load

+Ensure the MAYTECH rx model is correct (it did not fit 100% on my print, measure error?) - Record the potting volume at about 190 grams of material, work on the cover to reduce that

- electronics schematic

- Check Flycolor / sequire ESC integration possibility

Pushed the project to github, under the freedrive name

Few of the items in the TODO list should be crossed before ordering prints, most critical one is the maytech RX holes that need checking, but both my RX are potted ^^

Im deep water starting 24L boards at 95kg.

Probably too late for this iteration, but have you considered putting the motor in front of the mast in reverse?

I think that could possibly improve things.

It would be safer.

You would have less tilt effect (nose up) from the motor.

Motor would be closer to centre of gravity.

You would probably have more laminar flow at the prop.

I think it could be structuraly stronger, with the back of the pod attached and the front pushing into the board.

Just a thought after seeing that otherwise completely weird contraption from Waydoo.

@Jezza Can you tell the current setting of your VESC.

It’s often mentioned that FOC should improve torque. On the other hand I think I remember some posts about FOC not working as good with water cooled outrunners.

So I’m wondering what could make the difference.

For me at the moment there is nowhere near enough torque compared to a generic 120KV 6384. 10mm more stator AND lower KV.

I was running the Flipsky 100A pro v2. I set the battery current to 100A, phase to 160A and absolute max to around 250A.

I have the generic 6384 and the stator length 50mm which is the same as the Saite 6374 and Flipsky 6374. The Maytech on the other hand is only 45mm.

You are a good human! You very easily could have commercialised this project and sold it for around 2k. In fact why not offer some kits so you can see some return on your work?

Been there, done that around 15 years ago with my company LMX bikes ![]() Enjoyed most but not all of the experience of turning a passion project into a commercial operation, I would rather keep this foil stuff as a fun side project.

Enjoyed most but not all of the experience of turning a passion project into a commercial operation, I would rather keep this foil stuff as a fun side project.

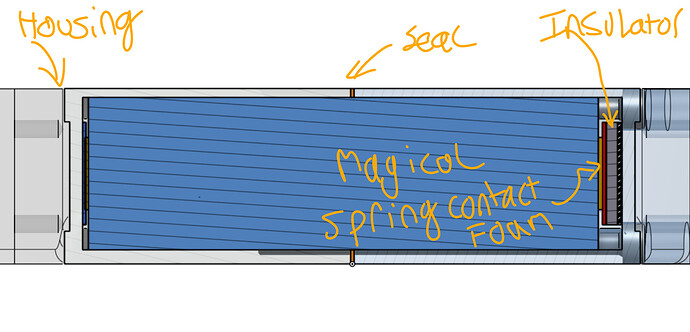

Planning a trip in morocco this winter, will need a airplane safe battery.

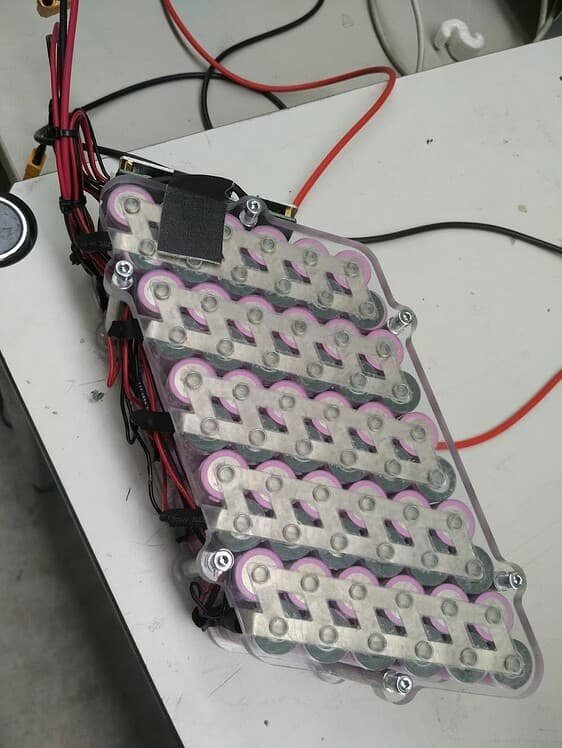

Here is my current strategy; Bring the parts and loose cells, assemble there, disassemble for flight back.

Balancing will be close to impossible to add, so will need regular service with a opus or similar.

Could be workable if I find this magical foam/pad for both contact and spring function.

Some things similar I did in the past, where a spring was pushing the nickel or copper on the cell :

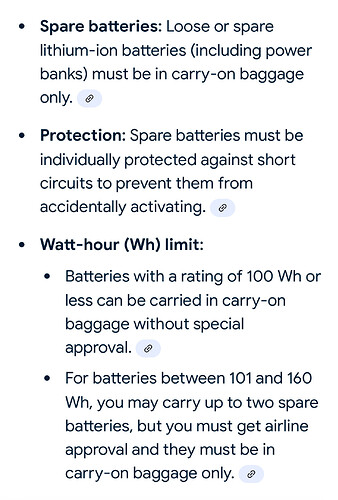

I wasn’t sure what general airline policy is around carrying “spare” battery’s. Found this on Google.

Seems like the 100 - 160 Wh is where it can go wrong with airlines. Approval on the way but not on the way back etc etc. Single cells a great concept imo.

I don’t know if this helps, but a Foil Drive user reported that in the regulations lithium batteries can be checked in if in approved box.

So he arrives at the airport with the relevant part of the regulations, the box with a printout of the specifications of the box, and the box with his FD batteries in it.

There is always initial objections, but after he steps through the process, always flies with them.

This was in the US with FAA regulations I assume domestically, but nobody else heard about it. It could be a thing for other regions and airlines.

I also thought that if I travelled a lot, to build a system with FD batteries as you can hire them all over the world.

But I definitely think if you can design a collapsible setup, it would be a game changer for efoiling and assists.

I had already 3 successful flights with multiple 6s1p batteries (<100Wh) in Europe.

I have 4 fullsend batteries and 4 homemade. Two <100Wh per person are allowed. Therefore I always travel with my kids ;-).

It is always an interesting experience to go through the safety check.

Sometime they don’t care at all, sometimes you have a small chat.

Single cells are definitely a good concept!

There isn’t really a general airline policy. It more breaks down into 2 things:

- FAA, CAA or other relavent governing body regulations

- Specific Airline regulations

When you go through bag-check, security will check you for national regs (CAA, FAA etc)

Airlines will not normally check other than asking you. But in the case of a fire and investigation this could be a massive issue if you are caught out.