Never managed to find time to publish the first build. We made our first efoil with a friend 2 years ago using the 65150 120kv, gong alvator and a reshaped sup. We probably had 100h of ride on it and it is still going.

I got my hand on a broken lift motor so after fixing it thought it was time for a 2nd build.

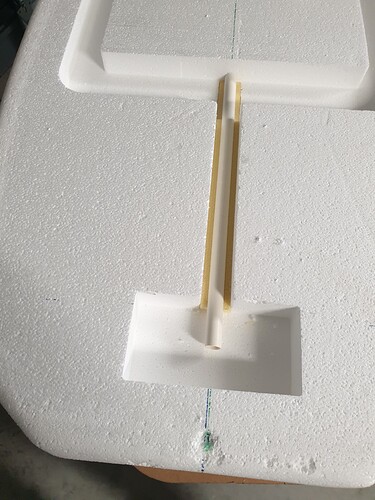

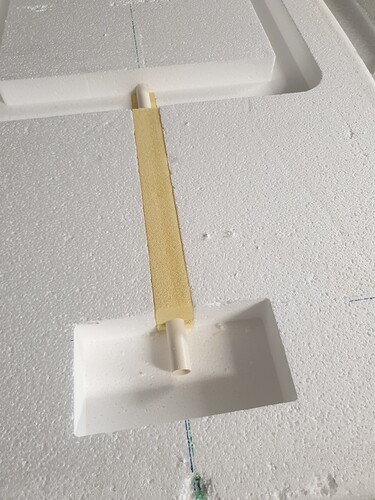

The board is 125cm long so I thought about having a 2nd enclosure at the front for the receiver and logger antena. Core is 15kgm3 eps. Reinforcement 60kgm3 hd pvc

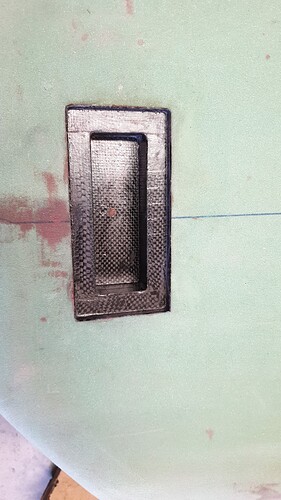

Full carbon sandwich deck and hull. 200gsm carbon plain weave on eps, 3mm 80kgm3 pvc. Top layer will be 300gsm carbon biax. It is a bit overbuilt but I want it to last and resist abuse

My gast vacuum pump died while applying the pvc on the deck, I had to quickly swap and use a homemade pump caled Big Bertha made with an industrial AC compressor. Issue is she is not pulling a steady pressure and deformed a bit the EPS. It really annoyed me but the result is still OK. 15kgm3 eps isn’t forgiving if your pump doesn’t pull steady. 25kgm3 way more forgiving if you can get some. Pic below are top and bottom layup

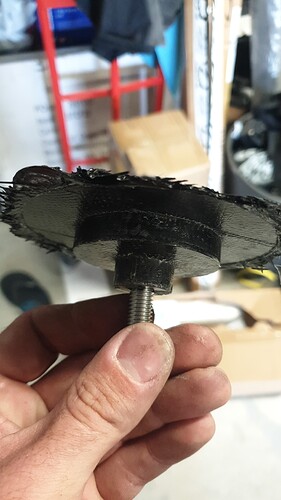

Sorry pics are not publishing in order… thanks Michon for the finger screw idea. I molded some carbon fitting so they sit recessed in the hatch. The hatch was molded with some slight convex rocker so it preload and close hard against the board. A lip on the hatch compress a silicone seal made from super soft silicone, 10-30 Smooth-on. I used diving weight belt in the battery compartment to sink it around 1.6m deep. No water in…

Board weight with hatch and seal and pad is 6.6kg a bit over target but not too bad.

I had a good session using the Opto seal 300A esc. Now I need to get this 75200 vesc going.

Efoil is super fun to ride using the Ozone Apex foil, super carry yet stable. Took a bit to adjust to the tony board size, I’m really glad I placed receiver at the front of the board.

Prop is the standard Lift, waiting to receive a 7inch. Once vesc sorted I will try few different front wings, higher aspect ect.

Could you tell a bit more about these as150 protection sleeves?

Beautiful board and a lot of nice idea , not a easy shape but nice for making the rear mast mount strong with the hatch lock water tight … trying to get my board around 6,5kg I will be happy

Any good place to get the hard foam ?

For the PVC foam Gurit sell some otherwise any composite shop should have some.

It is an idea from Michion. They are pole waterproof cable connectors, you drill the center then fit the as150 conmevtor in it. I think he posted the link on his build. Will try to find it

Very nice build!

How /what glue did you glue the pvc core to the carbon plain weave(that was on top of eps)? Thickened epoxy maybe or something else?

this is beautiful ! seriously ! wow.

did you mill the board yourself ? or did ya use a CNC?

Thanks, I used a CNC but had to do it in 2x step as my bed was slightly too small. It made things a bit harder…

It is done under vacuum. You apply the carbon on the eps, then place the pvc on it and vacuum everything I squeeze a tiny bit of epoxy thickened with phenolic microballon on the pvc in the tricky spot. The trick is to preform well the PVC with a heatgun and use relieve cuts

do you believe it would have worked without the PVC and only (way more) carbon fiber?

how did you ensure that your foil mast is not creating any water ingress into the batterie/electronics compartment? I’m searching also where you put the water cooling input/output?

beautiful work! it’s so dope. would you share your board design? I would love to replicate your build and even get an ozone foil & mast for that matter!

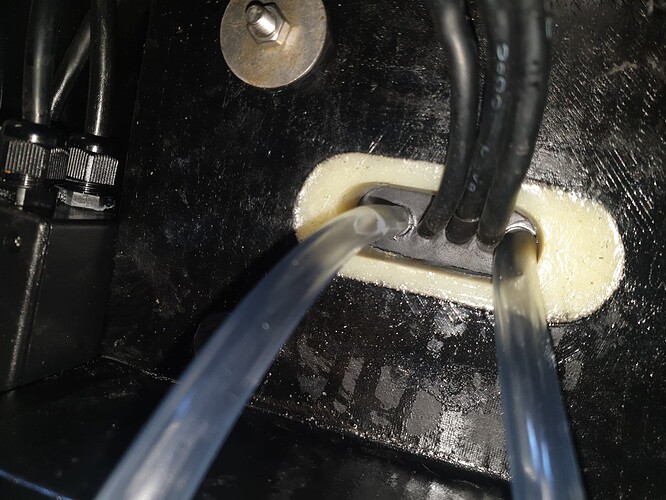

You would be ok using carbon over eps, you just need a denser eps blank 25kg/m3 or even 30kg/m3. I have a siicone seal between the baseplate and the board. Motor cable going through and 2 tube for cooling. Return cooling don’t go all the way down, only 3cm past the seal.

Happy to share the board design. The Ozone mast isn’t the easiest to modify, you will have to drill the core out. It is tricky and really easy to screw up

Thanks, so its all done in one shot( the the carbon on the eps and pvc on carbon), must be a bit challenging to get it all right before epoxy starts to cure even with slow catalyst. Impressive work must say!

Yes in on shot under vacuum. It is the process to build windsurf board. Slow hardener and thermoforming the pvc to the core shape make things easier

Cracker of a board! Nice to see you got the Lift motor back up and running!