Thanks for your experience on the 120cm.

2kg less or more is not so important for me. My V1 board is around 45kg with 14S8P 21700 cells.

I will stay clearly under this  but as I don‘t laminate the compartment, I don‘t want to resign on these extra reinforcement.

but as I don‘t laminate the compartment, I don‘t want to resign on these extra reinforcement.

Good experience under heavy conditions with my V1 board…

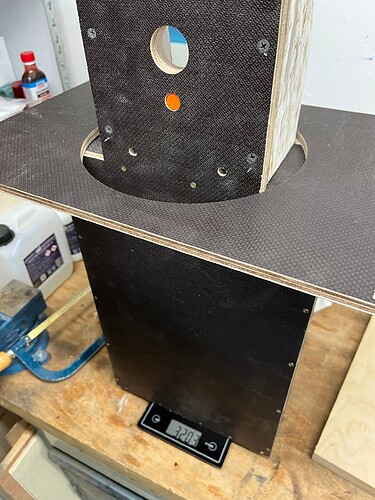

The battery weighs 4.8kg. 14s4p Samsung 40t + smart bms 100a. Built into the board.

Recharging via the same cable as discharge

Board 4.5kg

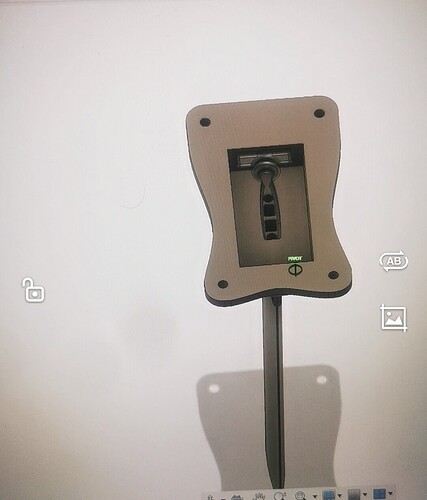

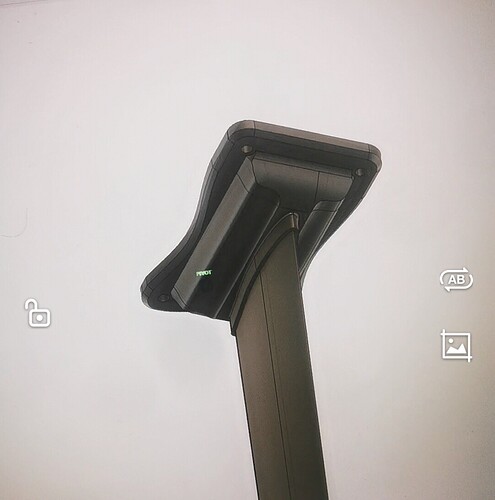

Vesc cooling on mast mast plate + 3d print box for vesc +wings +mast +motor= 6.9kg

Total 16.2 kg

Now next project for next summer I want more lighter about 15kg max. Little bit change board weight, mast plate with esc box, with my motor weight 2kg! 65161 weight 3kg.

Screensho

t_20231106_111954|401x499

You must understand that the lighter the weight, you spend less electricity you spend.

yes, that‘s clear. But 3kg less or more compared to total weight of >100kg with me with ~85kg+x depending of season, is acceptable in my opinion.

With V3 board the plywood will be then replaced by CFK…winter 2024…

Small is nice in some ways, agile and lighter but ideal length for me is 135-145cm, then i have at least a chance to fit on the board on starts and stops

(when flying i don’t need the board at all😀)

Now, on 120cm, i am lying with most of my shoulders and head overhanging the board. Especially on winter rides it gets a bit annoying.

My board is around 115cm.

I first tried on flite that is around 160cm but I like mine more.

It is harder to start for beginners but we are past that already

Hi, for me. this concept worked like a charm. Plywood box for skeleton…I used 3.5 mm plywood + 2 x 2 layers of 180 gr/ m2 glass…

The board has been ridden 2 to 3 times a week since February until now.

The summer in Greece, I was teaching my daughter and then it was 3 to 4 times a day…when I managed to charge the battery.

What are the specs of your batterie? Looks very big.

14s10p, 21700 cells.

yes, look big. I started building the box for 16s10p, but I stopped at 14s…

And I have plenty of space in the board - box…

No lightweight

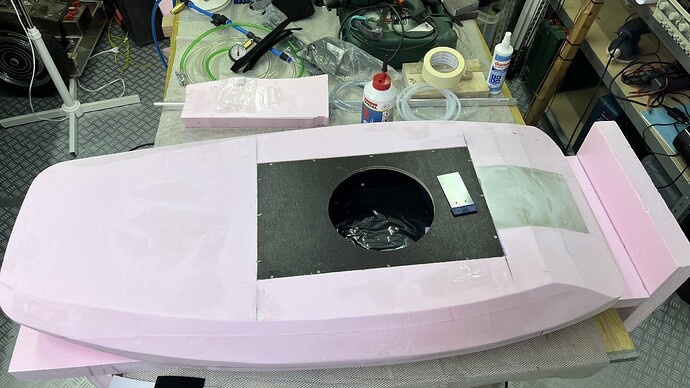

Original Gong square M6 nuts under orange caps. Will do some glassing over the caps to have it 100% watertight.

Bottom radius shaping (nearly) completed. With 180 grinding paper it took very long. Better take 80-120 next time. Scratches have to be filled up before glassing.

First time glassing with vacuum. Only pressing after manual application of epoxy.

2 lasers of 160g on inside surface of box cover. Reinforced to stand on later.

Hi, In my opinion, to achieve the best results, you should at least use peel ply and breather fabric.

There is peel ply and soaking fabric (breather fabric?) on the glass!

It´s upside down to not press the glass through the hole. I could slide a little bit otherwise.

OK, my mistake. Sorry

No problem, hard to see… ![]()

Bigger update. A lot of glassing the last weeks. 5 layers 160g/m2 on each side. Last layer with coloured epoxy, topcoat also coloured. Then some stickers and some topcoat over it.

Five layers!? I hope you’re planning to do some icebreaking with it ![]()

Too much? I like it robust ![]()