What thickness did you use on the pvc box? Why type of pvc?

PVC -U / top plate is 8mm / bottom plate is 10mm / side plates are 10mm / round parts 3d printed

All parts are screwed and glued together

The Box from Mike is very nice!

I have it see at the german meeting

How are you strengthening your 3mm aluminium plate where you attach the foil?

Looks great and thanks for the info! What did you use to bond the PVC-u?

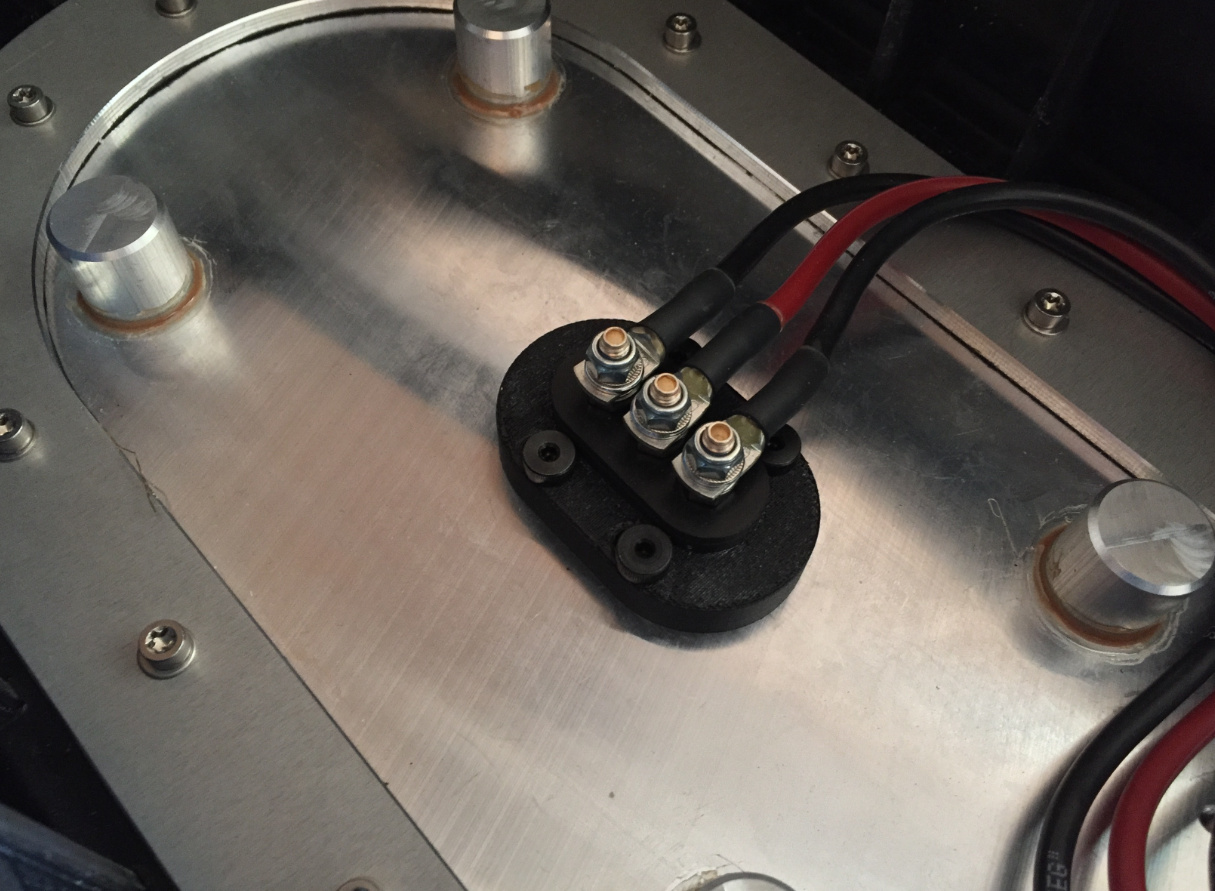

The 3 photo, you can see a 2nt 3mm Alu, it is weld with the Ground plate.

I’m using technicoll® 9411 - and at the round 3d pinted parts (Polyamid) plus technicoll® 9603-1

Hi Mike!

Is there a chance to share files for 3D print of box (12 individual parts)?

Uauuuuu, perfect solution!!

Just superb ! Could you comment on the water tightness ? How do you solder or crimp those male and female connectors ? Any pictures ? Wondering if those LAMTAC are also used inside the LIFT electric box for the battery for example.

A link to buy those ODU connectors individually ? Found ODU

ODU have a nice solution to connect the 3 phases of a motor :

Wow that is some nice battery building! Looks neat! One of the best I have seen.

Hi Danny - thank you

I’m sure you know the BMS very well  any news about it? Still available? Maybe I will build a additional battery…

any news about it? Still available? Maybe I will build a additional battery…

Mike

No problem! Credits where they are deserved any you certainly deserve them! There are about 3k units around now (and the battery building skills spread wildly  ) and I believe there is a new wave of assembly coming. Multiple parties have build them in the past.

) and I believe there is a new wave of assembly coming. Multiple parties have build them in the past.

Yes its still active and there are some software updates coming and if my Sundays/weekends allow for it also some hardware updates of the esk8 bms. For the past two years I have only been working for one costumer and I think that will continue like that for a while ( so the majority of my capacity goes and will continue to go to that ). At some point I would love to make a BMS (hardware) that is a bit more application specific to the larger electric vehicles, listening to my mailbox with a spike over the last months during covid there is a serious demand for a safe and adaptable battery assembly.

Hi Mike,

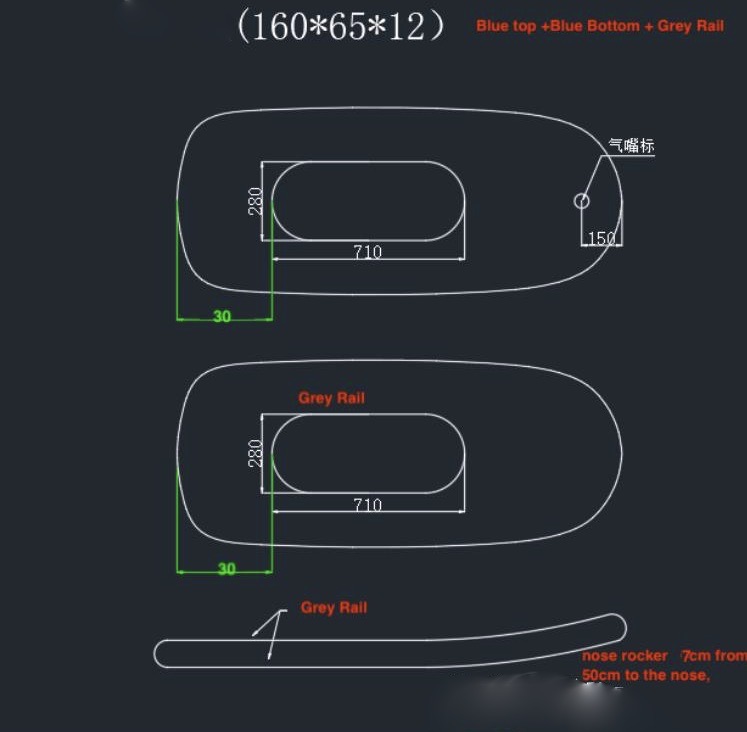

the build is awesome. I was inspired by your box design but could not figure out the right dimensions. I’ve luckily started experimenting with EPS to find the right fit before building the final box  … for now I did not find the right design with a good fit and easy install. Either its impossible to put through the hole or I fear that the fit is so loose. I have the following size of hole and would welcome your advice of the dimensions of the box:

… for now I did not find the right design with a good fit and easy install. Either its impossible to put through the hole or I fear that the fit is so loose. I have the following size of hole and would welcome your advice of the dimensions of the box:

The next one is inspired by your design, but if the EPS is fitting exactly into the hole I can’t get the smaller wooden panel through the hole if board is uninflected

I realized that the hole gets smaller when fully inflated, but its not that much bigger uninflated to put the wood through…

I realized that the hole gets smaller when fully inflated, but its not that much bigger uninflated to put the wood through…looking forward to learn from you and how it could work out

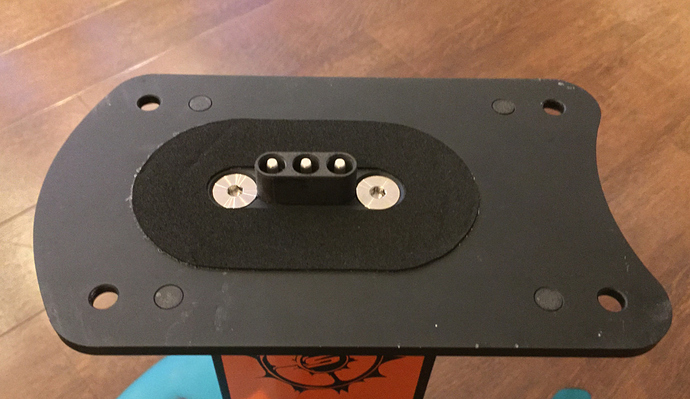

One way could be to sandwich it with distance tubes an screws. That’s how I did it. Search for “Daniels geared inflatable”. I successfully run it for quite some time, it works and it is stable but a bit tricky to assemble. It is rather heavy too, due to the aluminium plate. The problem with my chinese inflatable board is that the hole expands when you pump it. Therefore the box gets loose if you only plug it from the top. In my opinion, this is the best solution: Another build from Finland (inflatable) - #4 by palsi63

Study it carefully, It took me some time to figure it out. Because it has some space in the front you can pull the board over the box if deflated. When inflating, it will stick. This open part could also be in the back, then the cables from the mast could be connected with connecters and enter the box from the side through cable glands (as I did).

Hi Alexander,

I’m glad you like my board

The inner area should be exactly as large as the inflated board. The topplate should fit into the eva-pad and the bottom should be small enough to fit into the empty board. If the material is very stiff, this can be difficult - especially if the cut-out in the board is not even. It is important that the box sits firmly in the board and that the thickness matches.

You can contact me by PM and can talk by phone if you like - I speak german

Mike