Hey everybody !

Have you seen this new 200A VESC 6 based ESC from Flipsky ?

Pretty promising isn’t it ?

Has anybody ordered it/tested it yet ?

Great if the product keeps its promise it will be great, I look forward to reading your feedback. Thank you for the link

I run 14s. So that’s like 59.1v at full charge. They have a line saying 60v absolute peak. Scares me too much to try!

Yes I think 14S may be pushing the limit for the original VESC hardware Tyler.

I don’t like how they say “200A Continuous” and there is only 10AWG phase wires, 10AWG gets hot at 80A continuous. In reality the phase wires should be as big or bigger than battery wires because motor current is basically always higher than battery current.

It probably would work though, assuming we cruise at 50% throttle at 55 amps its roughly 110 A continuous at the motor, this scenario is more on the high end, but it is still well within this ESC’s limits.

@jakebarnhill1 I also don’t think they’re trying to power a motor that’s a couple feet away from the ESC. But isn’t the C80100 with 12AWG wires? What do you use down your mast from the ESC to the motor?

Well, I guess the 80KV version is more like 12AWG phase wires, I’ve never seen it in person.

My 130KV C80100 is equivalent to 10AWG or higher phase wires. I have 10AWG wire through the mast because that is what fits best, but it has good cooling being aluminium and underwater. Everywhere else is doubled up 10AWG because when riding hard the single 10AWG cable gets very hot, enough heat to melt hot glue.

This ESC would be worth trying out I think

I’ve already ordered one. It’s currently going through customs. I will keep everyone updated once it has arrived.

I originally wanted to try their FSESC 6.6 that is rated at 60A continuous I believe, but then they announced this one, which has a flat heat sink to better couple a water cooling heat sink as well. I think the other ESCs they made were rather designed for E skate (and air cooling). This one aims more at us, the E foilers.

Anyway, I’ll post pictures and test results here in this thread. Let me me know if you want see anything in particular.

Cheers.

I sent an email to Flipsky asking for a demo ESC and discount for the community.

I’ll let you know how this goes.

I have good hopes, eventhough I’m always skeptical with chinese specs.

I bought the 100A VESC from Maytech, which they claim can withstand 100A continuous, but is gets really hot past 60A.

But as @jakebarnhill1 said, even 120A continuous is enough (6000W continuous power at 12S- 50V !)

Is that with any additional cooling?

You are right, they often over-exaggerate the specs!

One thing that is misleading is the motor vs battery current. If you are drawing say 20A from the battery at 1/3 throttle, the ESC is actually handling 60A. The motor is running at a lower voltage so the input power still equals output power. So a correctly rated 50A ESC can only handle 25A battery current at 50% duty cycle (half throttle), because at this throttle level, the motor current is at 50A and half the battery voltage. Hope that made sense as I am no expert.

With my 130KV 80100, it uses 170A at the motor to get onto the plane, even though the battery current is less than 90Amps.

Does someone already tested the Maytech 200A or Flipsky 200A Vesc6 successfully in an Efoil?

Not that I’m aware of. You can get it for £180 here the the uk though.

I am waiting for my Maytech 200A. I will try it on 14S (I know it is risky) but without brakes, so voltage should not exceed 60V

I received my Flipsky VESC 200A a couple days ago.

I got a lot of work to do right now. I’ll post some photos tomorrow and hook it up to my 80100 and/or 6384PG via VESC tool As soon as possible.

nice, when you have time can you tell us which vesc tool are you using (if it reconizes it), which is the hardware and firmware and if you can update it to the last one ?

thank you

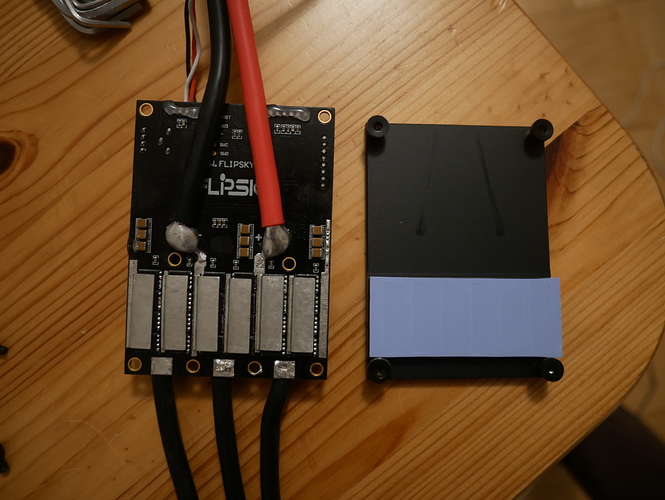

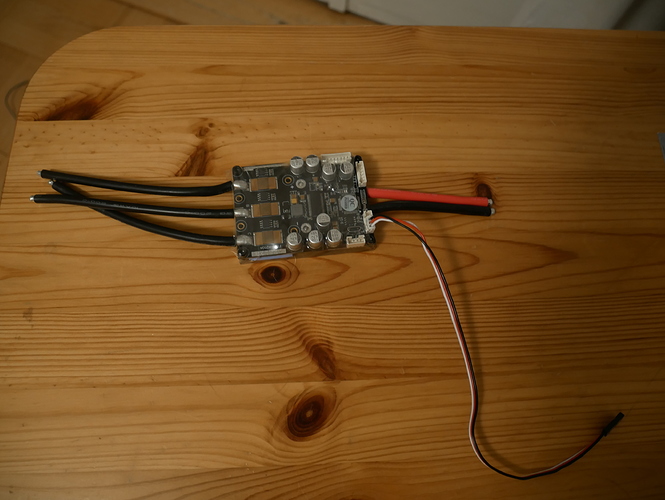

Here are a few pictures I took today.

It is very compact and has a flat aluminum bottom plate, which is (heat-wise) connected to the FETs via a heat-conductive paste, which is kind of gooey, so it adapts to the shape of the FETs and conducts the heat nicely.

I just tested this paste and aluminum bottom with a thermal element and it seems to do its job nicely. I will keep you updated on this in real world testing though.

The flat bottom is perfect if you want to attach a water cooling heat sink, which i will do.

There are 8 !! FETs per Phase, if I see correctly. The FETs should be the same they used in their previous ESC ( NTMFS5C628NL) - data sheet can be found here:

The rating should therefore be alright, regarding the FETs. Again, real world testing still to come, but it as of now it looks very nice.

Couple of things I notice: the FETs are conducting though their plastic casings rather than their drains where the heat can come out the easiest. Junction to case rating is 1.3C/W, its probably 1/5 that for junction to drain pad, then they still need to get through the thermal pad.

It’ll be drawing about 12-15mA of switch current at 10kHz, comfortably under the 30mA rating of the DRV8302. @Jasey could you measure the gate resistors with and Ohm meter?

It has 8x 100uF 63V capacitors. The best 100uF 63V smt capacitor on digikey is this: EMVY630ARA101MKE0S Chemi-Con | Capacitors | DigiKey

190mOhm, so 8 of them could have an impedance of as little as 24mOhm, and as much as 50mOhm. That is high compared with a 60A VESC4, which usually has 3x ~500uF 20mOhm capacitors. I don’t know if a standard VESC4 is overkill or if this is undersized.

The layout is very good from a noise perspective. There isn’t much room for inductance there, I bet the high frequency switching noise is very small. This is the biggest threat to electronics in a system. It must be small enough they don’t need large electrolytics to filter it out. The board is also well designed for cost. It’s a shame the bottom has so few components on it, its just the transistors and a few resistors and nothing else but a logo. They could have made this board an inch smaller than it is.

I bet it can handle 110A motor continuous at 48V. But I doubt it can do 200A into the motor for more than 20 sec. Not sure what the word “continuous” means anymore.

Edit it says 800A peak! No chance it can do that. Not enough fets. I bet that means it has 100uOhm sensors.

Any real world stats yet?