Many thanks Virus,

did you ever get to foil with 6S batteries?

i still need to test my build, but i only have 6S at the moment. I can make a serial connection to make 2 batteries pack to have a 12S, but wanted to try with 6S first.

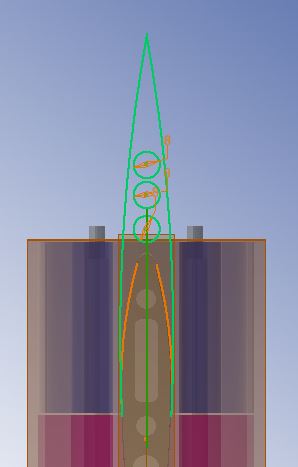

This is a 65150 type clamp concept (yes I will share the STL files when finished) .

This is a first cut concept only, it will be a compression clamp on the back of the motor, aluminium 6061 rods with studs threaded in. will use the rods to transfer the radial torque & a forward plate with a nose cone TBA design.

any advice is welcome.

Design looks good. How do you plan on bringing the phases through the clamp and into the mast?

a forward mast deflector , not sure who did it first but I have seen a few build that have done it. Builders: how not to drill your alu or carbon mast! - Foils & Boards - FOIL.zone

a forward mast deflector , not sure who did it first but I have seen a few build that have done it. Builders: how not to drill your alu or carbon mast! - Foils & Boards - FOIL.zone

Hi everyone!

from the pictures for the 65160 motors it seems that they are using distributed winding. It means these are PMSM motors not BLDC (like FR ie. concentrated winding). It means they would require at least VESC controller as it can drive it in FOC mode.

I am pretty sure that 65160 can be used with regulars ESC like swordfish with trapezoidal drive signal but I wonder what is the performance penalty?

Any toughts?

Yes, based on the photos, you’re definitely correct about the Hobiba motor being PMSM, and not BLDC. I’m interested to see how they stack up when run with a trapezoidal supply. I would still happily take a punt. Maybe we can ask the manufacturer for a concentrated winding.

From what I read you can use trapezoidal voltage to power a PMSM but it create audible noise vibration and poor efficiency. Did you notice noise with the Swordfish Virus?

PMSM are in theory more efficient, less torque ripple than BLDC if driven correctly so that’s not a bed thing.

That would mean Virus first results would be improved using a VESC in FOC mode as suggested by Mike

In general FOC will yield better efficiency (not necesaraly power on BLDC) as it is energizing all three phases all the time and thus using more copper to create magnetic field which in turn creates less copper losses(p.s. BLDC driver energizes only two phases at time-and third using for backEMF sens).

I had previous experience with VESC on foil and it is quieter in FOC mode.

I suspect that FOC with PMSM could give better efficiency,power and less noise…

Can anyone measure rotor diameter of 65160 motor?

So we can compare it to FR rotor which from picture looks like 43-44 mm.

As rotor diameter directly influences motor torque we could compare two designs.

Also stator lenght would be more useful data than overall case lenght…

Lots of noise with the Swordfish running 80100.

Well Jezza should be able to test I think the arc200 got a FOC mode

Can you run FOC if you haven’t got position feedback? Is it possible to use the back EMF signal for position FOC?

I guess yes , I run foc with no sensor in the motor , openloop … I am not experimented enough to tell if the bemf is used all the time…

FOC is not using backEMF and it doesn’t need sensors. It is using current sampled at high frequency to estimate rotor position. You can check on Youtube there are few good videos explaining FOC. Not so trivial math behind it…but it works great. Especialy for high inertia loads like longboards the start is much smoother without audible cogging.

And less high pitch noise as it uses sine wave drive signal and thus produces less harmonics…

Testing sensored motor with efoil would be interesting

Are you running the 65150 FOC Alexandre? What vesc are you using?

All good I read your build 75/300 that’s a beast.

FR motor + vesc 75/300 foc 60/130 30km/h 1250cm2 wing , 82kg

Do you have any photos of the FR motor, including internals?

What are the option to run the 65150 FOC at 14s? The 75/300 and A200s are just really expensive, the VESC6 only take 12s…