Yes definitely nice build but there’s a ton of modifications needed if he wants to get decent speed, better impellers, intake, batteries.

I’m talking about the guy in the video,

A lesson I’ve learned from my own project is that your jetboard intake must scoop water as you go, (impeller should be almost fully submerged until you reach planing speed, then, during planing, your impeller/nozzle should be about half in the water ad half in the air) many diy’ers kinda skip this part (me included) to “avoid drag” and so they build the bottom way too flush with the intake expecting the jet-pump to magically suck and lift water off the surface, it’s not how it works, you reduce your potential speed significantly.

I’m back at it with the 100mm motor configuration.

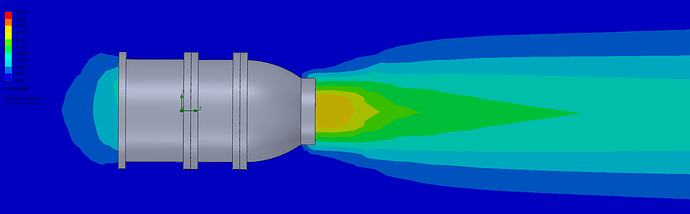

Working on a multistage prop to achieve a goal of around 100lb/s flow rates… if the motor can handle it. Ill chime in with some cut-ways as I get to them. So far it looks around 200lbf thrust @ around 75fps.

Here’s a snapshot. Likely going to increase the impeller a bit to get a little more velocity. A goal of around 80-90fps with 200lbf of thrust should get anything moving 30-40mph on the water.

(confused in metric  )

)

All good friend.

80fps = 25m/s

200lbf = 890newtons

So you’ll need >20kW , which ESC are you using?

Not necessarily.

My last design made 40lbf at about the same speed pulling 2kW. Shooting for 10kW.

The math doesnt add up. Even with a 100% efficiency

I would check the maths.

We’ve already tested the low power variant and measured power output and power draw. Look above 100 messages or so.

Working on a multistage prop to achieve a goal of around 100lb/s flow rates… if the motor can handle it. Ill chime in with some cut-ways as I get to them. So far it looks around 200lbf thrust @ around 75fps.

In metric that is:

flowrate 100 lb/s = 45 kg/s

vel 75 fps = 23 m/s

Force = flowratespeed = 4523 = 1030 N → ok

Power required (100% eff) = 1/2 * 45 * 23^2 = 12 kW

But then you’ll have losses in your esc, motor and propeller, so you’ll probably be at >15kW? Doesnt your CFD program give you the input power?

and It becomes even worse if you aim for your 80-90 fps your’re aiming for.

Problem is that the energy depends on the square of velocity, while the thrust increases linearly…

If you want to have 5 times the thrust with the same “efficiency” ( thrust/watt) compared to your smaller jet , then you’ll need 5 times the are to keep the same velocity. That’d bring your larger jet to 64mm * sqrt(5) = 140mm, so it might be better to switch for a propeller then??

(btw, i’m just talking about static thurst here. In any case, if you’re looking for speed, looking at static thrust is not really useful IMO, jets are meant to be used at speed, so i don’t know how useful it is. If you want acceleration, then it’s great to have this large area, but the drag will be huge at higher speeds)

I don’t disagree with the power calculation. I came up with 12kW as well.

The thought was to shift flow rates or thrust to the desired 10kW. Meaning we could settle for 150lbs of thrust if its at a higher flow rate.

At 48 volts this puts us at 200amp draws. We simply can’t do more than that. More than 48v is dangerous and more than 200a will melt wires. Hell 200a will melt wires if the water cooling isn’t effective enough. Not to mention beat up the battery nicely.

My CFD is more focused on flow characteristics, and this is where my greater efficiency came from on the last design. I make sure to avoid random pressure potentials, and cavitation. It allows me to tune the pitch of the prop to allow for the least force on the impeller, while maintaining the higher flow speeds.

This is a completely different impeller design to the last so you start to lose me talking about simply increasing the size of the jet. I haven’t fully decided on the size yet, but know that I’m working below 100mm still. Pitch and RPM characteristics greatly effect the output of the jet as well as the impeller shape itself. There are many ways to skin a cat with a jet. I’ve seen at least 3 different ways to pressurize water within a jet all dictating 3 different impeller shapes.

Electric motors still have a ‘moment of torque’ to them, and within this process I’ve not seen making an impeller larger than your stator work out well for anyone. It will over-torque and draw amps to the moon. WITH AN IMPELLER SETUP - I cant say the same for open propeller designs.

As far as static thrust goes… its the best we can really come up with lacking expensive test rigs. Thrust is one component and velocity is the other. The best I can do here is ensure the velocity represents a standard while maintaining thrust output.

oh, Ok, i see.

as for mentioning your previous jet, I just did it because you mentioned that you were able to achieve 40lbs with 2kw and expected 200lbs with 10kw , which did not match with the data you were writing. In any case, i see that you’ve been studying this for a while already. Have you run simulations with the inlet velocity >0 ?

You’re spot on!

For more information around this, look at the differences between mixed-flow pumps and axial flow pumps. I would call my design some hybrid of the two. Very similar to jet-ski designs. Its axial but its not.

My CFD might be limited in capability. I can either run an “external” study or an “internal”. Even though this is an impeller its defined as a “external” study to see how water moves around the prop. I could possibly set some constraints and close off an inlet and outlet as an “internal” design and set a flow rate at the inlet. Then we should be able to determine some thrust outputs and velocities based on a moving craft. Problem is, we wont know if the craft is actually being propelled at the speed of which we are saying is flowing at the inlet. Regardless it will tell us things about what happens to the velocity or the thrust.

Let me get happy with some of the static testing and ill give this a shot!

One note on motors (specifically the tp100 and aps100). First, as far as I can tell, ALL of the APS motors are chineese. They are made from a chineese manufacturer, and this is why the chineese knock-offs look so similar. Probably literally the same motor rebranded.

Now the motor pictured above is NOT a TP100 replicate. It is a APS100 replicate, and it has noticeably smaller wiring. We need TP100’s not the smaller winded APS100. APS is likely meant for HV low amperage- stay away from it. (its noticeably cheaper too. If its less than $400 its probably not the right one)

So guys I did a test of a 80100 at the weekend but unfortunetly had water breach again. It wasn’t powerfully enough to get the board above the surface and with my weight plus the 21.5kg board wight with an original volume of 80l it wasn’t enough

I think for the only solution is 420kv tp100 at 13s 80mm 3 blade impeller

The oly thing I will add to my statement is that my impeller is 100mm long which could have created too much load but I’m no expert just trying different methods

1 seul moteur ex de vélo électrique 1500W ou plus qui entraine 2 jets par chaine on peut régler vitesse de rotation des jets

Wow!

Just read through this discussion. SO VALUABLE.

Thank you all for contributing.

So, thinking about a jet board build…

This discussion woudl suggest;

- Two smaller jets are less complicated in terms of motor/jet availability.

- Probably 65mm jets with TP100 motors

- ESCs??

- Running large wires from battery to dual ESCs.

There are the MHZ 65mm jet setups;

https://www.mhz-watercraft.com/shop/en/jets/573/powertrain-jet-64?c=110

What are reasonable quality alternatives?

Is there a areadily available, tested 65mm 3D printed design?

I have a complete Jet 64 powertrain to sell including MHZ jetsurf board. Only used once. Half price compared to MHZ.

Don’t need the board or the ESC.

Will you seperate?