I have 10guage wires from motor to esc and 8 gauge from esc to battery. Battery is in this box totally sealed and nothing gets hot battery is bairly warm after full efoil run.

I have the same 10awg to esc and 8awg to battery. I’m worried in a box it atleast gets fresh air and water splashed on it. sealed in foam the heat will have no escape. its just so easy to just put it in the foam so really trying to get away with that unless anybody confirms its a bad idea. :).

What size battery and how long run time you thinking?

I’m running a 12s3pack 50p 21700 molicel 20ah I’m getting 20 to 30 full efoil. Even in foam I can’t see them getting too hot. But your right my box is thick but does get wet being fully submerged when board in water so yes it will stay cooler.

13s4p 50p 21700 Molicel. I have no clue on runtime and it will just be used as a foil assist for getting some waves. Also use as a tool to teach my kids to wingfoil. (can’t have li-ion get out of control)

Why do you need to run 13s my 12s has too much power with 6579 motor I have backed throttle of to 80%

That’s where yours might get hotter drawing more volts . 12s is heaps. I Cruze at half throttle most the time.

My issue is I don’t have the skill to pump yet so my run time is reduced I’m not having any luck getting high on mast so I’m thinking of running motor low on mast to see difference if drag. Do you have a pod design yet I can’t seem to find one for this motor ?

13s4p is a perfectly fine battery configuration for assist (maybe slightly on the bigger side but not an efoil battery). The 13S will push a bit less current than a the 12S pack for the same power. 4p will divide the current across 4 cells. So overall it will generate less heat than a 12s3p like @Airtimeasto is using. If you’re using high quality power cells from Molicel I don’t think the pack will get too hot. It’s always the esc that gets hot.

Here’s a recent example of a completely enclosed battery-in-board. And this is an efoil, which is more demanding on the battery as it runs continuously (not intermittent like foil assist).

210 lbs and like really small foils. this is just to pull me into big waves i cant get into on my own. Yes I had a guy in france make one and he now has it on his website. I’ll go find that for you.

so the pod is for 63mm so you will have 1mm each side over but he adapted this for maytech screw spacing.

Thank you. Yes due to building this inside of the board i got a fully waterproof ESC that will be on the bottom of the board exposed to water etc.

Thank you for this insight on current.

Thanks for that info good to know I didn’t realise 13s would draw less than 12s👍🏽

Airtimeasto, correction i bought all this a while ago. Take a look at the link i sent you. Its for the propellers that he adjusted screw inserts for the maytech motor. For the pod you will find he has a spacer that does the hole adjustment for the pod. He made this spacer after I had already ordered but it looks really good. I just drilled out new holes in the regular pod to fit the 6579.

Sweet thanks . I’ve been struggling to find something now I just need a prop design that I can reverse for my dual motor boogie I’m starting

This guy at KParts does owe me a favor. Wonder if we could convince him on a counter clockwise prop. Whan you hit him up on Whatsapp he will be happy to talk to you and perhaps get something made for you. This is how we got into these custom 6579 items.

If you have the STL of a clockwise prop, you just need to mirror the piece in your slicer (BambuStudio, Cura, …) and you get a CCwise prop for cheap if you send it online or to a friend… Just sayin

Great to see Kparts offering hole spacing for the maytech 6579 now.

Kookfoil at 210Lb 95kg on small foils I would say you are definitely going in the right direction with 6579 kit as it has the power and torque needed. but be realistic with how much CAPACITY you need to get out to these big waves especially if you are making it non-removable.

I would suggest 10s3p is your minimum battery size if you really only want to use it as assist.

The 10s3p (P42A cells) 12.6Ah (529wh) 2.6kg that came with my michobby kit didnt last long enough for me ~15-20 mins 10-15 starts in flat water was a short session.

in 3P, it got warm (but not hot) when used continiuosly. (85kg rider) should be fine mounted in foam.

Airtimeasto 43.2v 20Ah seems like a good choice of battery size

Many other assist DIY-ers aiming for ultimate light weight find 10 or 12s2p of 21700 cells= enough power for 6384 foil assist but with limited run-time unless you have good technique+ use a longer board, larger foil, weigh less etc etc.

OEM Foil drive assist products manage to get going with much smaller/ lighter packs but they are less powerful: I would disreguard anything 28V if you want to use a fun board and foil with folding props

Max std 28v battery = 362wh

Slim performance 40V is TINY 166wh 1kg = only 11s1p!

I dont really know how it produces enough power from the discharge current of 1 cell and must run HOT! (not sure which cells are used but pretty sure since these have been around for a coule of years that they are molicell P42A which deliver max continuous 30A)

The P45B =45A continuous and the new P50B supposedly delivers a whopping 60A continuous!! which would really be an advantage in 1p format

It sounds like the latest most powerful foildrive max power 6384 motor and battery are now finally enough for heavier riders with smaller foils. A 95kg mate was able to downsize his foil from armstrong 1080 to 880 with latest parts.

NEW Max high power 594wh 40v 2.8kg =11s3p (i believe)

latest foildrive is probably equivalent torque/ power to 6579 stainless prop 10s3p or 12s3p plastic prop but run time likely better with foildrive.

My 14s4p 28ah (1156wh) is overkill in terms of voltage (goes pretty fast!!) & lasts around 40 mins

Airtimeasto Same as you I’m finding it difficult to get off power for pumping. As soon as I let off throttle the board nose-dives. I’m an advanced kitefoiler- dozens of tricks in the bag but my diy efoil setup is not easy to ride

Anyone else looking to build a foil assist I would advise that THE MOST IMPORTANT factor is getting the battery weight as far back as possible (above the mast ideally)

since Im only really using my set up for full efoil, I’ve just drilled a hole in the mast to run wires through for a more efficient low motor position.

You’re standing too far forward to pump, you need a big shuffle back when you go off throttle

Great advice I’m running one of my packs is the p50b 5000 molicel and that gets me 30mins run time full efoil and just warm end of run.

I totally believe reason for me having to stand quite forward on my board is the offset incidence I’ve run in my board that I’ve built is too much nose up. I when my parts arrive I will be building assist with battery box in camel pack with esc and only 6384 motor mounted to foil. I want to try my apple tree board and my wing ding board they seem to have more level tracks with deck.

Plus I need to get out on the assist more often to get practise in. Need more time on water with it to get more control and balance.

I’ve ordered the reverse props from Kparts he’s great to deal with.

I’ve started working on my dual 6579 motor boogie but have to wait for Bremote v2 to turn up. Shape my own boogie but may test normal boogie for positioning first

Good skills, can you link to pics of your setups?

P50b 60A discharge is impressive eh! Beyond what we need given the runtime we need for foil assist or efoil.

I really want a full day of testing every different foil and prop combination with my maytech diy board.

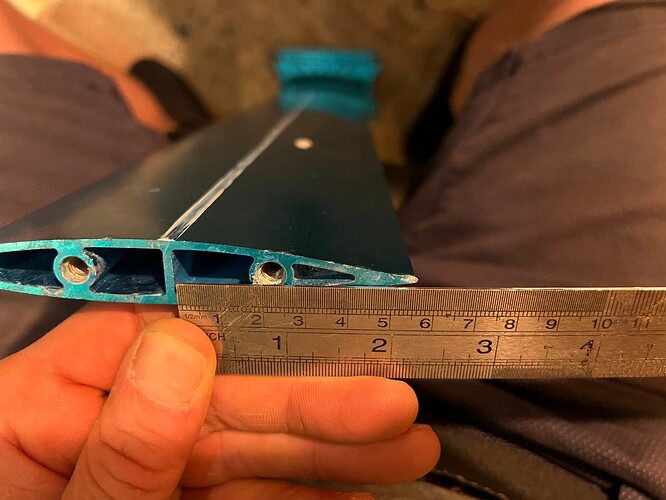

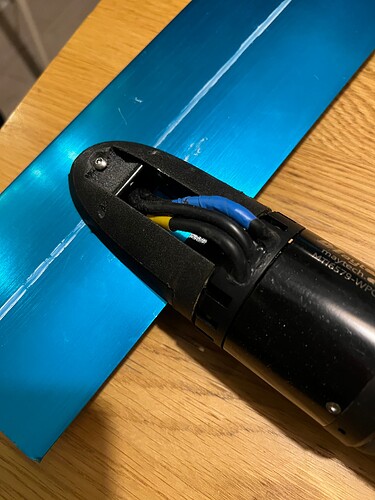

Ive just commited to drilling a hole in my cheap F-one aluminium mast for efoil low position with less drag. For an aluminium mast, f-one are quite light. 2.07kg inc foot for 85cm (only 200g heavier than sabfoil 82cm carbon mast & 500g more than Fone and 750g heavier than No limitz)

15mm thk is decent for speed and can feed 5.5mm bullet connectors through. Hopefully not too much more flex.

I can have high position integrated mast also by removing just 1 bolt and feeding wires through.

just need to mould in a wire cover

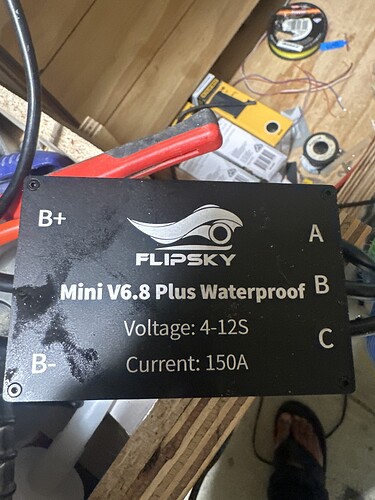

Well my backpack setup was finished and programmed vesc and motor everything was working fine when I left home as soon as I powered up in water it stopped and I can’t seem to get it running again I think it’s vesc I bought from flipsky something somewhere has failed

I think I’ll go back to esc they are much simpler. Has anyone ran a 160amp esc on a 6384 motor before or should I get a 120amp esc?