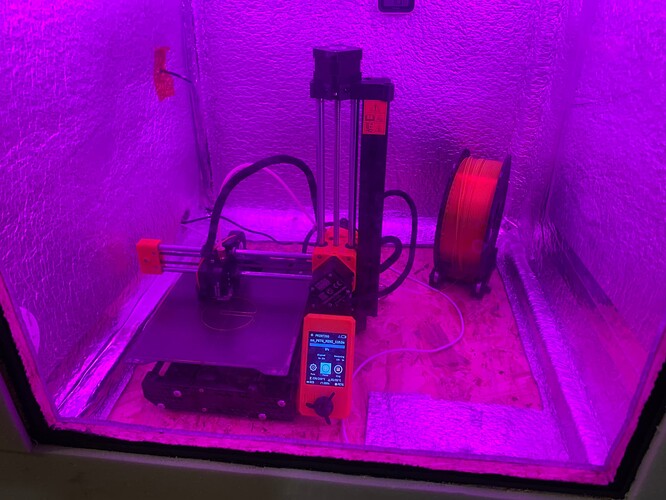

moving on with the prints.

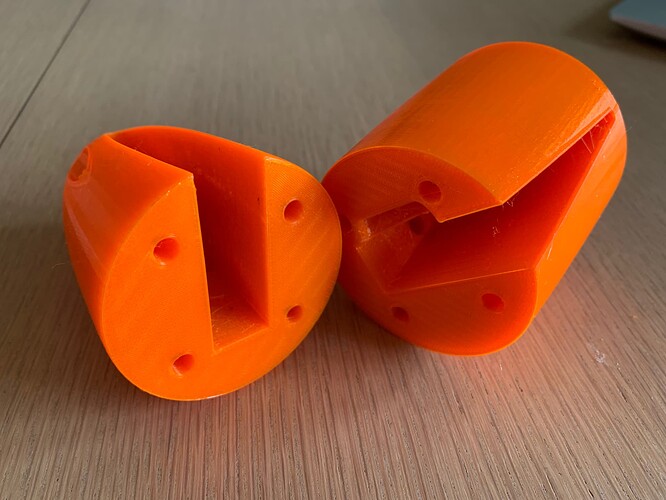

I’ve also added the inserts to attach pelican case

and did a bit of sanding

as you’re reading this, the inserts have been put in place with microballons & epoxy… and the remaining epoxy has been used with additional microsillons to soften and perfect the surface.

mast pod is almost done. I’m waiting for the screws to attach the motor and take this opportunity to add some silicon here a there.

any idea on how to avoid rust on the mast which is aluminium but has no more coat on it? black paint?

some orders have arrived. The mast & motor pod is now almost complete. I’ve added water sealant to keep the inside isolated and clean.

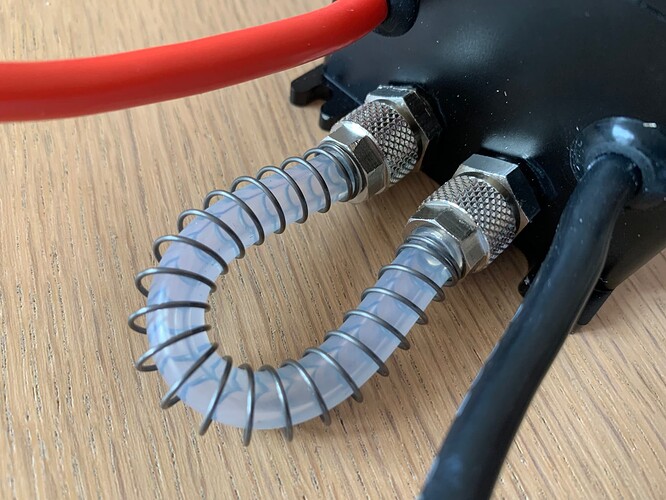

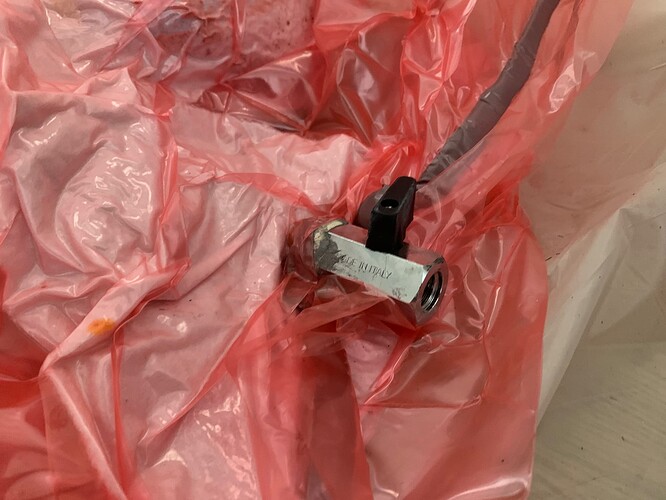

I also took care of the 75200 FESC with more appropriate water inlet/outlets. I’ll secure them with teflon tape.

@Foilguy FYI

Thanks for showing the 75200 upgraded fittings. I just started a thread on this issue.

Check the 3D print fittings from @windego. The return would take less room than the bent tube version

Can you provide source / info for the fittings and the tubing you are now using.

Well done it looks much better than original.

Curious about how the fitting works. Appears to be some sort of compression fitting?

I’ve added teflon tape and yes, compression fitting; bulletproof!

Some progress on the board, next step will be the vacuum & composites part !

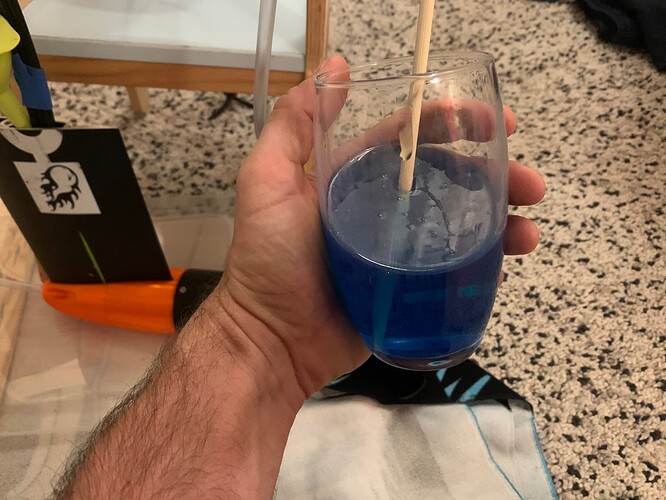

day of the vacuum. All safety measures have been taken into account.

I’ve also adjusted the 3M scotchtape to different areas

and time for some composites. This is going to be harder than steel ! I’ve added a lot of left carbon as reinforcement on key areas. then 3 overlapping carbon tissus and also some fiberglass. Definitely overkill.

20°C curing !

it went pretty well !

I’ve fixed remaining holes with qcells and epoxy on the bottom of the deck

Curing !

some of you asked for it, so here we go. That’s the upgrade I did to the pretty poor water intakes on the Flipsky controller

this morning I’ve sanded the other side of the “board” and added the fibers. Under vacuum.

Before

After

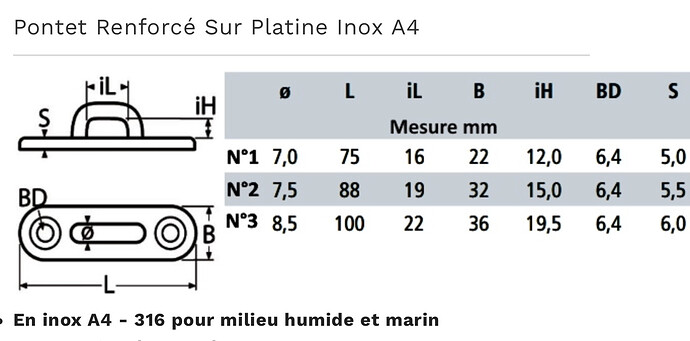

I’ve also bought two of these to attach the boogie rope. one per USBOX. I expect them to be rock solid according to the specs. Probably overkill.

this morning, I sanded the bottom and will come back to it with more colors later on. I’ll make it more funky in the future with less separation on colors.

I also took care of the top.

good day folks !

I added a pressure plug this week and also sanded the top/bottom before the next step : glassing.

I love the colors and effort you put into this! I’m just started building a tow boogie but being the lazy person I am, I just bolt all the stuff to a body board. Will be super interesting to see how this turns out!