Yes, even PLA works well if the print is good.

I had a similar issue with printing the prop. I ended up adding a skirt where the blades begin printing at about .035mm thick, additionally print at a slower speed with some hop and retraction and 100% fill also higher resolution (.016 rather than .02mm layers) It took 28+ hours to print but came out perfect…I have a file with the skirt added to a design I found on another site. If I post the file, I will post the original designers name and website where I found it…

Hope this helps…

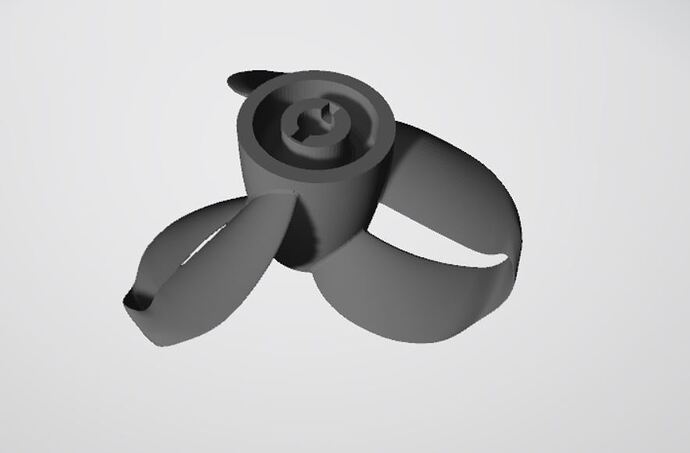

Regarding the looped propeller design I would like to share my thoughts here:

I think the main question is if the potential savings due to the improved cavitation make up for the double amount of leading edges. Even if the blades of one loop are in line there must be more losses than for a single blade. But lets pretend the efficiency of the prop is the same there could still be the advantage of blade stiffness for example when 3D-printed. Could be a nice solution for self printed props. Then you also don’t have any patent issue in my opinion. I made a design trial based on a wageningen 3-blade base prop with the smallest blade size adjustable in the tool. I bent one set of wings forward and connected the loop. I want to compare this prop to some regular ones on my build. Printed prop is allready ordered. I probably did not hit the perfect design here and I did no CFD check but anyway I want to test it. Due to the mentioned reasons in the chat above I will not share the design on a plattform but if there is some interest to share some design thoughts you can PM me.

Cheers

Nice piece of work. As you mention, does doubling the wet surface compensate the drag decrease ? Looking forward to seeing your first test results.

IMHO, the problem is not sharing the STL since the design is public and published in the patent but making a profit selling a printed prop for example.

Completely agree. Just want to avoid any discussion in that direction. Anyone is welcome to make a parallel test with that design  . Just let me know.

. Just let me know.

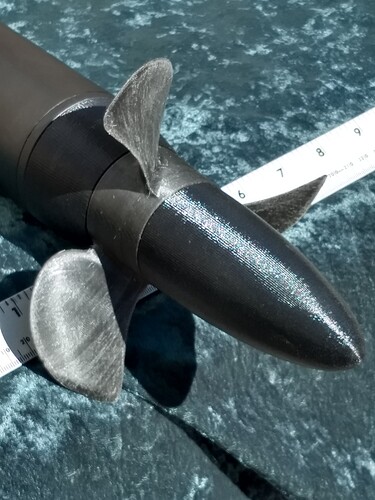

I printed this prop and will be testing as soon as the water warms up and my prototype board is ready for the first dunk and fly sea trial. This is one of two I will be testing and I will post the results when I crunch the numbers…

Here’s a couple pics

Fresh from the oven

80100 motor B-series prop, PLA 3d-print + epoxy

Slightly higher pitch version of my previous favourite that delaminated during ice riding.

If it works well then i’ll upload the file.

Hi Lars, looks like you got a more sophisticated epoxy curing station like I do. My print is fairly thin and mainly just for optical evaluation. But I think I will still make some tests with 1/3 power or so. Lets see if your epoxy layer keeps the props from bursting. Did you try CF reinforced PLA yet?

Yes, the previous prop was both CF filament and CF laminated. Laminating works really well and the props can be super thin - but fragile, hence the ice delamination.

im goimg to try this one ou in the upcomming summer and let you know

Ill maybe cut it down by a little as it wont fir in my hub or ill make the hub slightly bigger

Did you test the prop already?

general question on the flipsky 65161 motors there is no Screwed shaft version like the maytechs have right?

KR and thx

My first test with this diameter/hub will also be this summer. My PM-setup with the same blade design was V1 for past summer, this summer will be V2 with flipsky 65161 and this prop. I have the Flite board prop as well for the flipsky motor.

Threaded shaft is available at BG.

Ok thx very much!!

Lets see how it turns out

may i ask where you got the file for the end cap ?(torpedo)

KR and thx

I put it together myself in a matterhackers app called ultimaker.

My 65161 FlipSky has a small threaded hole in the end of the shaft to secure a cone termination.

Thx very much for your reply!!

Hello guys.

Im trying to make propeller for my efoil based on torqueedo desing but i need help…

Dont know how to finish it, dont know how to sharpen the edges.

Can anyone help me finish it?

here is design i made so far.

https://drive.google.com/file/d/1-EmeP48EseR3gbErXDNqYog7xNm14YyE/view?usp=sharing

Have you tried it (noise, speed, …) ?

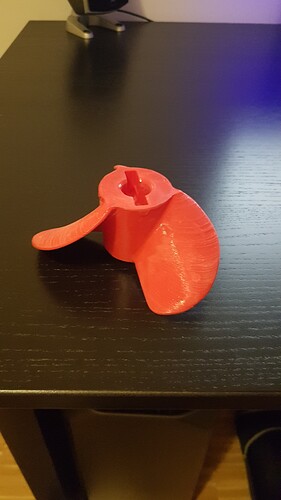

So I designed my own prop… wondering if it will work…

Made with only two perimeters with PLA+

I covered it with epoxy. I put the prop in a bag then I did the vaccum into it. The epoxy is well pressed against the prop but some sanding are needed after

Only 250w power… ![]()

The water level was not high enough

Hello guys…

Anyone wanna try this propeller just for fun?

https://drive.google.com/file/d/1gga05Th9Wl6dVLxr5q_WHd-kiIejTGJh/view?usp=sharing

https://drive.google.com/file/d/13itG0JnUzJHBFGESfXJ8dGayr7XTml3p/view?usp=sharing

Two blade and three blade version…

Diameter is around 170mm

Pitch is around 130mm