Good question…

Printed props are so light that balancing maby dont have that big impact…

I have tryed few printed props on my buld and didnt notice any vibrations, all unbalanced.

A propeller imbalance may not be reflected in the selection of the entire e-foil. However, shaft run-out will definitely occur, resulting in reduced bearing life. Static balancing is therefore important for any rotor, especially one with a speed of 5000 rpm. Static balancing of the propeller is very easy.

However, every DIY propeller should be dynamically balanced. If it is not dynamically and statically balanced, shaft run-out can increase dramatically. This then results in an even faster reduction in bearing life.

On my new Flite propeller, I found a static unbalance error of about 0.150 g. Although this is negligible, I will remove this error as it is very easy for me to do.

Additionally, on my new APS 63100 140 kV motor, I found that it is recessing the rotor shroud. The fault is due to the shaft hole not being exactly on the rotor axis. If I don’t correct this error, it too will result in shortened bearing life.

It also contributes significantly to shortened bearing life if there are only radial bearings on the shaft (motor or gearbox).

Partial damage to the bearings will eventually start to damage the motor shaft seal (inrunner type), resulting in water ingress sooner or later.

Therefore, as a general rule, any cause of run-out should be rectified as soon as possible.

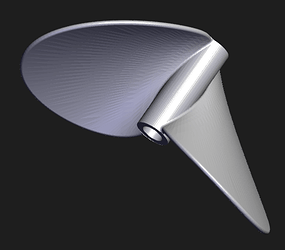

Few of my new designs…

If anyone needs 130mm diameter cca 130mm pitch propellers.

https://drive.google.com/file/d/1xsMq4ilqDScm3TrDbWMS9Vfmk8fixIU3/view?usp=sharing

https://drive.google.com/file/d/1xsMq4ilqDScm3TrDbWMS9Vfmk8fixIU3/view?usp=sharing

https://drive.google.com/file/d/1DXhQB1gV83bOrD52wPuCC9JOTfaJD_go/view?usp=sharing

https://drive.google.com/file/d/1imXtr2Q1cTfIjoFxfalZzuhh3goj52wX/view?usp=sharing

A long time ago, I had the idea of reinforcing my propeller with epoxy and vacuum. As the sealing was not very effective, I did not dig enough to see if it is useless or effective.

Yesterday I received some sealing bags for the 3d spools and tried again. Unfortunately the bags are not ultra thin and it will leave some marks when the epoxy dries.

I tried on a prop without epoxy just to see. And I was quite surprise to see water coming out from the prop… This prop was out from water since 2 months!!! So I do believe that if I can pull out water I can push in some epoxy!

How did your sharrow-style looped propellor work out, in testing/durability/power usage?

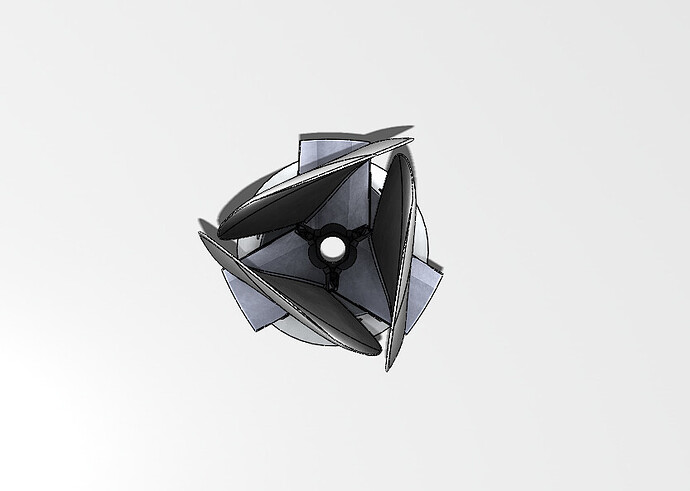

To be honest I have not tested it yet. I think it will not hold up. Its ABS covered with epoxy. I should try anyway. I have shared the file with another person from the community recently. Maybe we will see some results there. I have concentrated on another prop which I am really happy with actually. Base design is also from this forum. I just made a stainless folding version of it with some minor mods. At least with my 65163 100kv setup this prop propelling me a little faster then with my FR props with different pitches. But I cant compare currents from my ESC.

Beautiful propeller, maybe the first e-foil propeller made from metal on a commercial 3D printer. How much did you pay to print the propeller?

Well it was probably done on a commercial printer but in a non-commercial surrounding i.e. University. Therefore it was only material cost for powder and gas. The rest was understood as practicing. At least for once. But maybe the next step would be printing with steel filament ultrafuse 316L for example. At sculpteo it would be around 50$ per blade. Hub could be probably done with a good reinforced filament. Or what I am looking into next to print the hub with internal lattice structure and then filling it with some epoxy and fibres.

Thanks, it’s all interesting information.

So it seems that the shape of the folding blades is a bit better than the fixed blades of the FR propellers (both Flite and Manta). However, to confirm this, it would be useful to measure the current and rpm.

Thanks for sharing! Its working perfect with my pacificmeister-build! Miles better then the original prop with duct.

Hi, i share this prop 133mmx256mm. https://grabcad.com/library/propeller-133mmx256mm-1 .I hope it’s useful.

Your prop 130mm with 10mm shaft

How do you block the pop in rotation ? Correct me if I’m wrong but for our use, I suspect the propeller hub diameter must not be too small with respect to the motor OD (65mm) in order not to mask too much propeller blade surface which becomes ineffective.

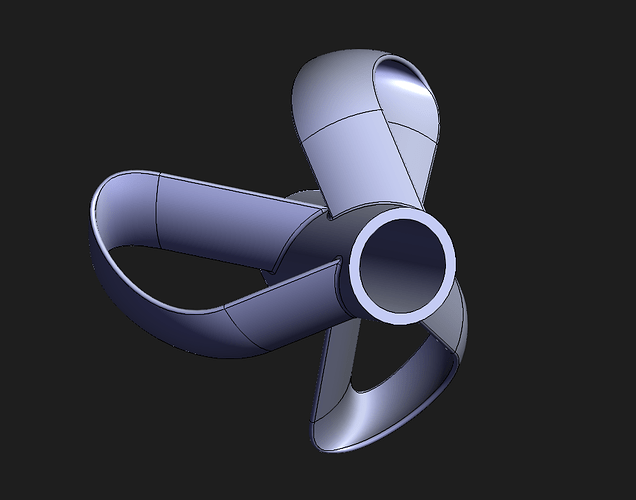

Hi, just sharing my own version of a toroidal prop like the sharrow.

Would appreciate any feedback

https://grabcad.com/library/toroidal-fan-blade-1

For anyone interested, I can cast your prop design in aluminum/bronze for a long lasting strong prop!

Hello,

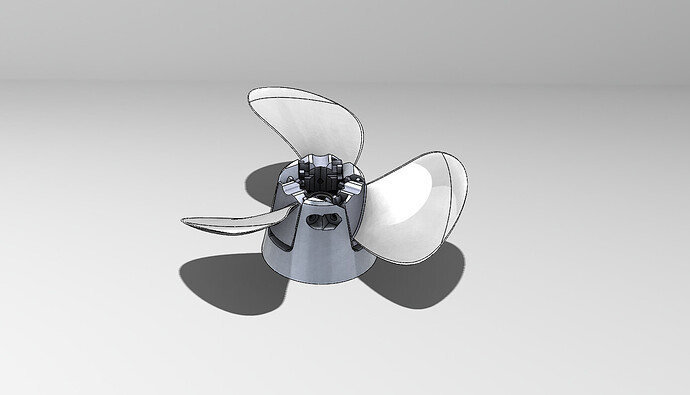

I have been working on making a folding 3 blade prop for my motor that I purchased from Jake last year. I started doing this since it didn’t look like there were any on the market that were a perfect fit for it. I struggled last summer getting one that would survive without breaking the blades off or shearing the hub but also generate enough thrust to be functional. I worked on it a little over the winter and came up with a modified design.

I was finally able to test it this past week. I was very happy with the performance. It appeared to have similar performance to the aluminum prop supplied by Jake. I printed the blades out of Prusa Polycabonate on my MK3s. The hub I actually had a company print out of sintered aluminum; however, I believe that the hub could also be PC and still work. I did coat the blades with some 5 minute epoxy to give a better surface finish; I do not know how much that contributes to the strength. I will say the PC is significantly tougher than the PETG, ABS, and PLA that I had been using in the past.

I still want to collect some data to see average power consumption. I haven’t been able to grab any yet.

Hopefully I can release some files soon.

Nice,

If you like I can print you some blades on my form 3 or binder jet.

Thanks for the offer!

We have a form 3 at work that I can use. What materials can the binder jet use? any aluminum?

I think it can but I’ve never done it, the post processing would be significant. I’ll check when I’m back!