Can you post a link to the two bladed Thingiverse prop? I tried to find it in this thread and couldn’t locate it.

Thanks

Can you post a link to the two bladed Thingiverse prop? I tried to find it in this thread and couldn’t locate it.

Thanks

This might be the folding prop that you were looking for.

If that doesn’t work try searching “efoil hydrofoil folding foil propeller” in thingiverse. I’m pretty surprised how much abuse this thing can take - I’ve been slamming into tons of obstacles in the river & it hasn’t broken - must be a function of the folding mechanism prevents damage idk (I’ve been using it on my paddle board not my efoil)

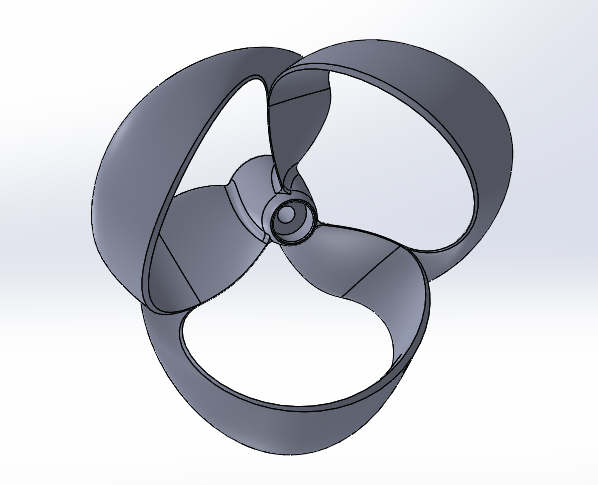

Hey, I took a prop @MaB posted and tried turning it into something toroidal. I don’t have a way to test it right now but if anyone has the time or the interest to try it out I’d like to know if it even works.

cheers

I see a lot of models here, but for some reason there is no real video of using a toroidal propeller in an efoil or foil drive.

I modeled one this winter that I tested a few weeks ago. It worked, but it definitely wasn’t any better than my standard propeller which is just a 5.5" diameter x 8.5" pitch aluminum prop. It also had a bit of vibration. I assume it was slightly out of balance.

Post here: Toroidal Propellors - #88 by Twstahle

As promised, here are my files for the folding propeller that I made. They are in the STEP format since I assume most of you will need to modify it slightly to use with whatever motor you are using.

https://drive.google.com/drive/folders/1lL6_WanJsaLUZ3LIX9PC0zQ5wyqIhP6a?usp=sharing

You will need three #6-32 x 1-1/4" socket head cap screws and three #6-32 nylock nuts to attach the blades. In my case, they have to be attached to the hub after installing the hub on the shaft.

Let me know if there is something wrong with the link. I think I shared it right.

Hi all,

thanks to Twstahle inspiration, I designed my version of 3 blades folding propeller.

I just keeped the shape of blades, area, pitch, profile and so on

It’s compatible with 6384 and 6374 motor.

At moment I’m printing the parts to test it on water ad maybe in the swimming pool for the correct measurament of trust

Pretty soon I will open a new thread dedicated to my foil assist construction

Step file:

https://drive.google.com/file/d/1G_JDTF1B9q5_iRpCMv7LCff4M66Pw4xM/view?usp=share_link

Video description from fusion 360:

great! Mind sharing the step file (or fusion 360) of this version of the hub?

BR

how much will casting cost?

What material did you end up using to print? I eventually settled on Polycarbonate (Prusa PC) because all the others kept breaking.

Hope it works out for you as well as it does for me!

That honestly doesn’t surprise me. That has been my experience as well until I started printing all the parts in PC.

Even my carbon fiber PETG didn’t hold up.

I think there is not enough material with those screw holes, It will probably break, no matter what material you build it from.

Definitely the weak spot for sure. The cross sectional area there is very minimal. I will test with the material I have.

I have been using the metal hub that I had made.

Tree blades propeller is working fine on 6384 motor

Fiber carbon reinforcements on all surface of the 3d printed parts is my solution

Nice work. How did you do such a neat job with the carbon fibre? Did you print the parts slightly narrower to account for the carbon fibre layer on top?

Also, how does it ride? Any noticeable improvements over a two blade folding prop?

Thanks.

My 3D printed PC blades broke today finally. I guess the stress is just too much for them.

I will probably be getting aluminum ones made up this week.

I do not recommend using the prop printed without reinforcement. It clearly still has some issues, but if someone want to modify it, go for it.