How could you possibly damage the motor shaft drilling a pin out?

With the wrong tools this could happen easily. If he got a drill press, he can drilling it out also. but before he can try the other options. @Flo98 please keep us updated.

Seriously - what would the damage actually be?

Sand the pin out in current position (#2) with 240 sand paper, on 360 degrees to remove the rust

Put some grease

Put nut in position #1 on the other side of the shaft

Using the vice, pass the pin back completely in the motor shaft

Sand the pin out in position (#1) with 240 sand paper, on 360 degrees to remove the rust

Put some grease

Put nut in position #2 on the other side of the shaft

Pass it through fully again, it should be easier as you polished both pin head surfaces

Put a reduced diameter short screw (under head length = motor axis diam) in position #1

Press with the vice to extract the pin fully

Hammer it out if needed

thanks a lot for the advices, i will try when i am back. Last time after trying again and not succeeding, i was keeping the pin for now. Corrosion seems on the surface / only using in water without salt

Giving feedback about VESC overheating and propeller change from Fliteboard one (7 or 6 pitch) to Maytech 4.2 pitch (with slighty bigger diameter).

My setup is now the Maytech 4.2 pitch propeller, with 200kv motor, 50V. I take off at 13 km/h around 1,8kW (40A-45A at 42V). Then current drops around 36A (at 42V) when flying.

I can fly max 20 km/h (and peak is max 25km/h, because of VESC reaching 80°C). That’s already really nice, compared to previous setup with Fliteboard propeller.

I would like to try to increase the max speed. My current cooling is watercooling thanks to dynamic pressure + passive cooling with an aluminium plate. For the first cooling, the rate of flowing water is not so fast because of my low speed.

For the second cooling, the electronic box is in some level of water inside the board. What do you think to put ice cubes in this water to increase cooling?

Or wait for winter…

Honestly I think if you want to build your own eFoil, better stick to known working designs. Even if it costs you some extra money, it saves you a lot of trouble and time.

There are plenty of working builds in this forum.

Could be simple and effective to add a fan inside the box.

But the remaining heating is a bit surprising, i think there are things to tweak. A log would tell more about the possibilities.

I got the propeller 3d print. But the diameter of shaft is more than what is given in the design. It doesn’t work.

How big is the size difference?

what is the diameter of the shaft?

It is exact size as that of shaft. I think increasing 1mm dia is enough. Thinking of taking it to a lathe. Or is it possible to sand?

A reamer should work.

sure, i was just trying to use a motor i already have. But finally it works quite well, i also reduced length of cooling tube

I got the inner dia increased in a lathe. There is a small gap between prop and main body. But it’s ok. I tried the foil today works great. Thank you for all the assistance. I am greatful.

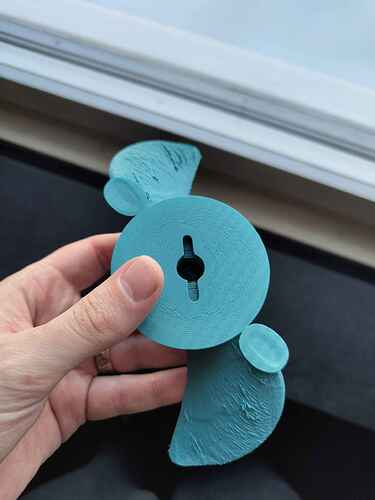

Printed a custom shroud for this to fit my 70165 motor and now printing this prop, gonna compare this, another prop design from Thingiverse and the Flipsky prop, we will see how it goes ![]()

I’ve been using that prop as well on a 65161 motor. It’s very quiet once up on foil, which is nice. My only point of comparison is the Flite prop. It does have less thrust than the Flite prop and takes more throttle to build up speed for takeoff. If you’re on a gun case it might be difficult, but you will have a bigger motor so maybe it will be fine. Curious to see how it works for you

Had this disaster print of the previous model as I tried to print it without supports but warping if the ASA-GF was pretty intense during print.

But this new design came out pretty nice, you can see the prop from the first picture also sanded and cleaned up, so I think with some light sanding and clean up its gonna look really nice.

I also have the first print, printed with minimal supports and clearly need some cleanup, but I will clean up them all and compare, will get metrics from a METR later when I start testing board to compare how all the props perform in real life.

Wouldn’t this been an option for maybe better balance point. To bring the motor in front of the mast with a special propeller like an airplane got it. What do you guys think?

I would be concerned about destroying the prop in a collision with a log, rock, sand bank, etc. Still I would love to see someone try it on their e-foil

Hitting those things is always to avoid. It only needs this type of prop. Everything else is the same as known already but the other way around.