sorry its 19mm. not 190mm*

also diameter of the bottom part of the shaft is 9mm.

Thanks a lot. Sry for my inability to provide one like this. I am just a kitesurfing instructor.

Are you working on the stl file sir?

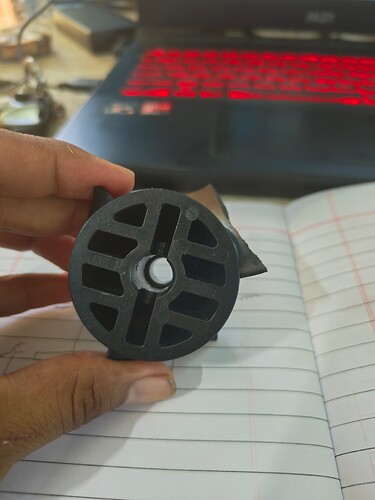

I’m working in fusion360. I have 3d scanned model in mesh. I convert it to solid body.

there is simplified 3d model for you in stl file. https://grabcad.com/library/flite-prop-1

best result with PLA, or Nylon-CF (PA-CF). Note than it can break at any moment. I ride about 300km and then it broke. To extend its service life, protect it from sunlight

thanks a lot for the file.

i have asked for the local printing company to print it for me.

getting it done using SLA technology.

they have either FDM or SLA. FDM looks low quality printing.

If you can get it shipped to ypur place, you might also consider buying an original one (it last over 1500 kmfor me). It is not very expensive.

I have ordered it. But does take more than a month to reach me.

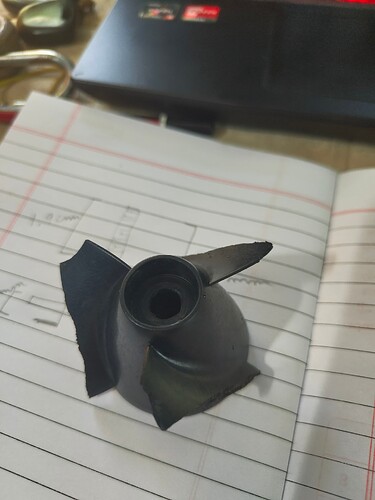

Can you describe what happened to cause this much damage to the Flite prop?

I was riding and hit a soil bed in the river. Foil came to a halt. I fell. I got the mud out from the front wing. Tried to ride. Was riding slow as hell. I turn the foil n this happened. Have no idea how it broke. Then I rode back with speed 20 moving at 1kmph.

May be u guys know what happened?

Does this mean you had mud stuck to the front wing?

If there were small rocks in the mud and they somehow managed to get to the prop while it was spinning that might be what happened.

How long did you run the damaged prop? It would be really unbalanced and create a lot of vibration in that condition. Hope you didn’t damage motor.

I ran for around 5 mins. It doesn’t seem to be damaged. Will know with the new propeller.

The propeller is broken semytricaly. So I don’t think it should have caused stress on motor.

I hope your motor is OK and you’re right in that you won’t really know until you get a new prop.

There are a number of threads here that talk about prop balancing and how minor imperfections (not just props) can cause cavitation that you might want to read.

The damage to your prop is NOT symmetrical other than there is damage on all three blades.

I don’t know how fast rotation is at Flite speed 20 so can’t comment on whether 5 minutes is a lot or not.

Fingers crossed till day after tomorrow. Il update

Thank you, I tried your method with a standoff (like a big nut), but i didn’t succeed to get the pin out of my motor axis:(

I also tried with a hammer, with the shaft on a piece of wood @sat_be

I can maybe hope the corrosion is only on the surface, not inside the metal

and still use this pin

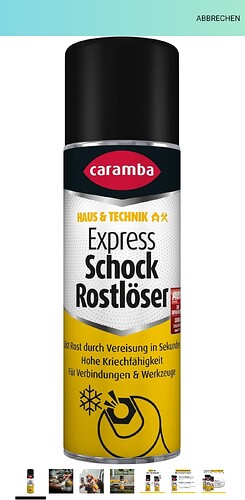

Heat the shaft and the pin up with a lighter and then cool only the pin with this spray or two icecubes from both sides. Do this 3-4 times. Then dip it completly in WD40 for 2 days. Shaft has to swim in WD40. After that put it on wood where you drill a hole 1cm deep before,that the shaft is laying complete flat on the wood while one pinside is in the hole. Then use a 500g hammer and hammer it out with one hart punch.

One night in Coca Cola , or make a flat spot on the pin and try to turn it before pulling

Why all the thrash? Cut it off flush with shaft and drill it out. Replace with a new pin that you trust won’t fail.

If he got no stand up drill machine its a high risk of damaging the shaft with that method. Coca Cola is also an option