Javaprop is getton looking but it works well. Tested three pops today in thrust tank, and specs were almost exact to what javaprop said they would be. Really amazing and is a game Changer.

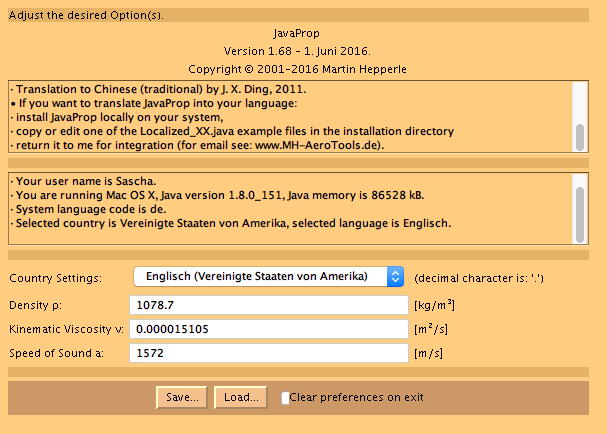

When using javaprop be sure to change the LAST TAB - OPTIONS. For water… or else all your props are being tested in air density.

I think the wings in Javaprop become amazingly small. Is this realistic, that such a thin blade can withstand the thrust? I already double and tripled the chord length, but by this the efficiency goes down.

I would have to make these blades out of steel, at least carbon.

It is calculated with Dia:17cm, 5000RPM, 7.5m/s, MH116.

Analysed: eta 72%

did you set the options tab for water prop settings?

SEE SETTINGS: http://www.diy-electric-hydrofoil.com/java-prop/#!/up

Is this really correct? I am missing one 0 in the kinematic viscosity compared to

It does not have much influence at the chosen RPM and velocity. So RPM is definitely too high.

I will try to get a motor with less kv, optimized for our needs. Maybe Alien 6384 with 65kv? What do you think?

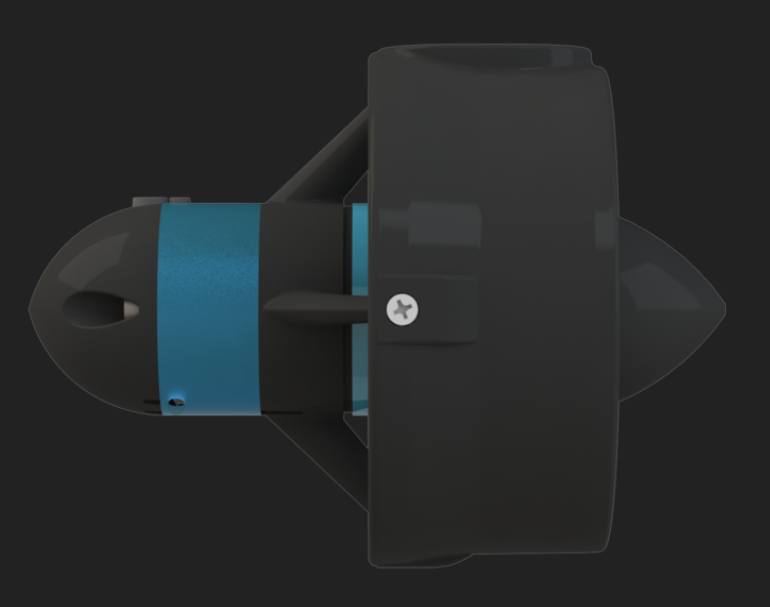

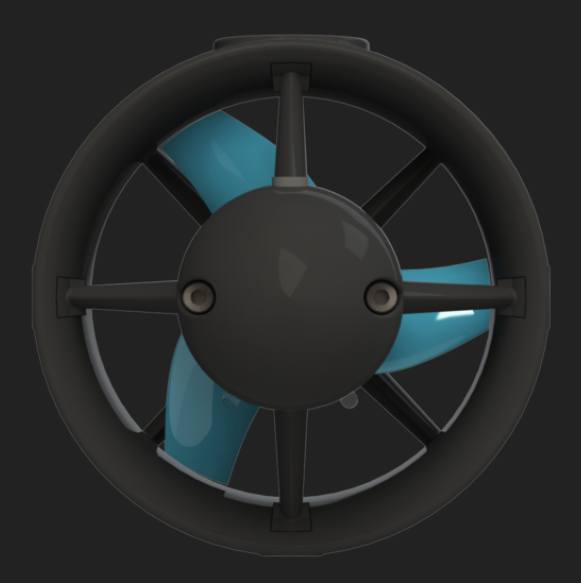

We tested three props this week two of them 80mm with different pitch, and a 110mm with very low pitch. Our best performance was a 80mm duct prop at 8750 RPM generating 20KG static thrust which is great given we were using the SSS motor 500kv which has very little torque.

The 110mm provided the same 20kg thrust, but its a big prop meaning larger duct to slow you down from high-speed cruising, it sits high above the fuselage meaning its easier to have the big blades come out of the water, and larger prop assembly costs 3x more.

Once our new motor arrives we should have 30-35kg thrust which is enough to get up riding with the 80mm. This is a super simple direct drive setup, small diameter profile and safer with a small prop. We will keep you posted!

How many amps with each setup?

We were testing this 80mm prop as well. works fine and we have 25kg thrust which is enough to ride our SUP-Foil. But we have a special wing with very sofisticated profile. Don´t know if it would be enough with a regular foil wing… Our Amps at takeoff & 50V are about 65A. Little less than with our impeller. we made them interchangeable so with 4 screws & about 5min. work you can decide to ride safe&fast impeller or more efficient ducted prop…

what the matter with this link chris?

it just goes to your landingpage

corrected link, thank you

Yes we did the same… we have 60mm impeller, 80mm duct, and 110 duct, all can be swapped in less than 5mins with a few bolts as well for easy testing and comparison…

There is also the bluerobotics way… But only 5 kgs of thrust

I wish they would upgrade their system to what we need

https://grabcad.com/library/bluerobotics-t200-thruster-with-blueesc-1

hello,

i made some test this week on 3 proppler:

1 aluminium from amazon

2 3D printed based on HIORT design

i measured : voltage before ESC / intenisty / speed of motor / torque on motor / Thrust.

this is my test lab :

this is blades:

my motor is out runner and start over heating

this is table of results :

my motor is really too small, i will go on 56104 SSS

in term of proppler, for same mechanical power we obtaine 25% less efficiency on 3D printed proppler

i will try to optimize my design on standard aluminium proppler

Excellent info. I will love to see your results on SSS 56104 !

Nice work Gobbla, and thank you for sharing the data. I hope to do some similar testing. Nice test rig you’ve designed and built too!

Could you add another column to your spreadsheet? If you have a column for thrust/watts it would give a good comparative number for combined motor/prop effectiveness.

Hi PowerGlider,

hi propeller pros of this forum,

I’m currently fascinated by JavaProp. I used it to calculate the propeller generated thrust for a given motor torque and rpm on one side and propeller diameter and pitch on the other. It worked fine to get an idea how a setup performs.

But would’t it be great to design the “perfect” propeller for a given motor setup instead of using one of the shelf that fits 80%? JavaProp seems to be a tool to achieve that, but also a tricky one for unexperienced guys like me.

Nevertheless I would like to start a discussion here, how to use JavaProp and CAD software to design a propeller according to motor specs.

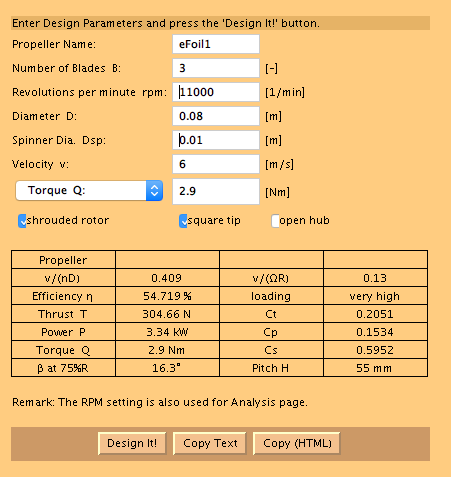

I started with the selection of an appropriate motor and ended up with the 290 KV version of the TP 5870.

With a 10s battery motor RPM is about 11k and torque about 3 Nm. The propeller diameter should be 80mm to fit into a given duct.

Before I configured the prop parameters I changed the fluid settings in the options tab to water by entering the following values…

After that I entered the basic parameters in the design tab:

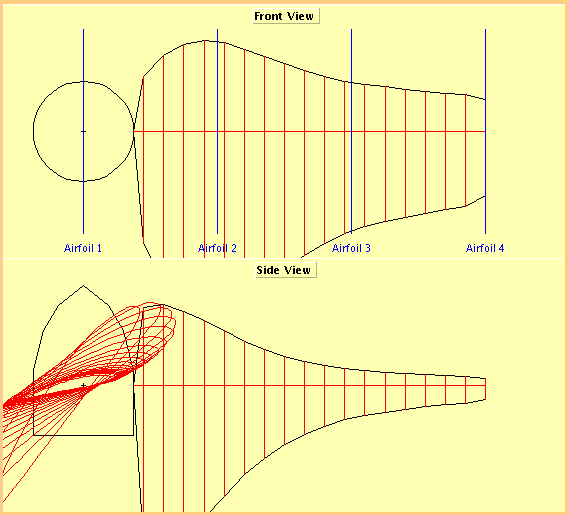

As you can see I wanted to design a prop with 3 wings and a desired speed of 6m/s (= 21 km/h or 13,4 mph). I also checked “shrouded rotor” for a ducted propeller and “square tip” for the same reason.

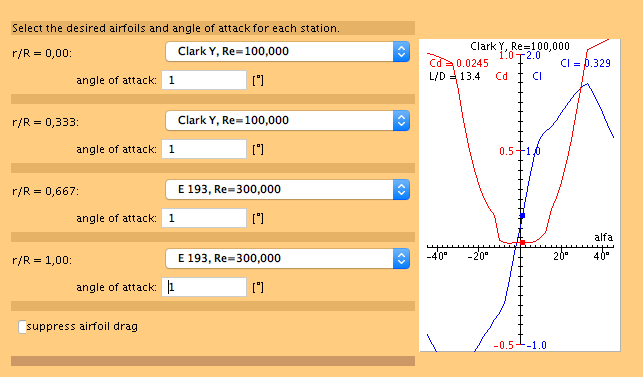

After that I selected a mix of airfoils that come close to a marine propeller (found them in an other forum) and changed “angle of attack” to 1 in all sections (see screenshot). The default settings will generate a propeller with an aircraft-like geometry.

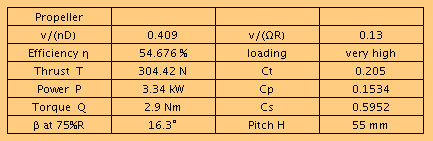

After that I returned to the design tab and pressed “design it”. I got the following parameters back:

The generated propeller thrust is 304N = 31kg. Pretty cool. On the other hand, efficiency is only 55% and loading is rated “very high”. Not that cool. A view on the “geometry” tab reveals the following.

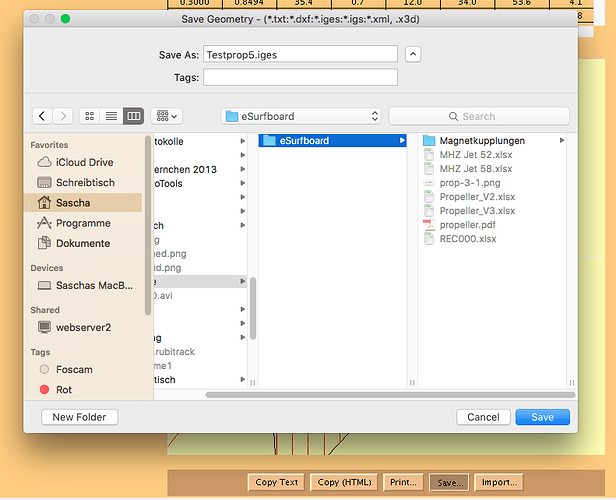

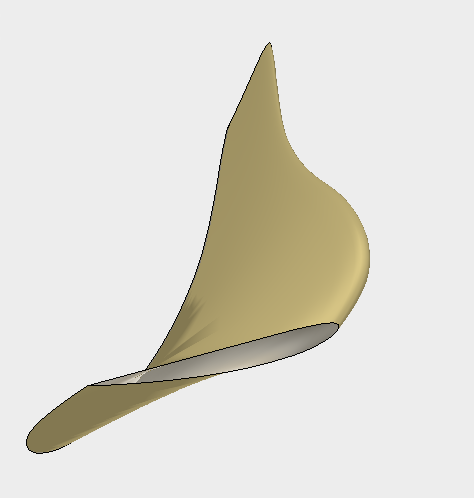

Looks pretty much like a marine prop to my unexperienced eyes. ![]() After that I saved the propeller (wing) as “*.iges” file to be able to import it to Fusion 360.

After that I saved the propeller (wing) as “*.iges” file to be able to import it to Fusion 360.

This is quite simple by pressing the “save” button and name the file “filename.iges” to a folder of your choice.

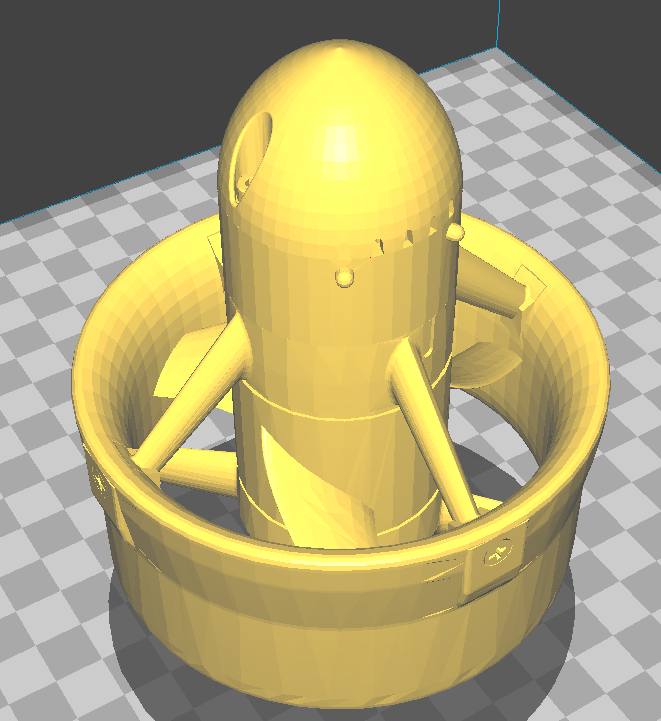

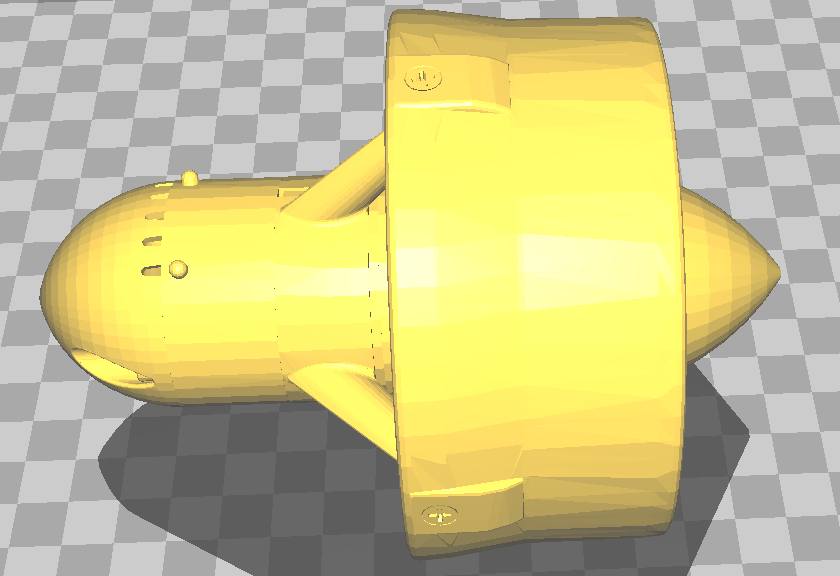

The result in Fusion 360 looks like this…

Looks quite nice. But you can see, that the side where the wing usually joins the spinner is open. At this point I have more questions than answers to create a 3 winged propeller out of this.

Fusion 360

1.) How do I close the open sides of the wing in Fusion 360 to make the imported .iges file a massive or at least closed object instead of an open “hull”?

2.) How do I have to align and combine the wing(s) to a spinner to make ist a working propeller?

JavaProp

3.) Is there a database or website with custom marine airfoils that can be imported in JavaProp? Or is that combination of predefined JavaProp airfoils as I used them appropriate to design a real marine propeller?

4.) There also seems to be an alternative to JavaProp. Anyone around who tried this one?

PropGen

In general

5.) Did anyone here design a working propeller with JavaProp and a CAD software that performed as calculated? If so, please share your wisdom. ![]()

Would be happy to tackle this with your help.

Cheers,

Sascha

I face the same problem when opening the igs in fusion. I am not able to convert it into a body which i could combine with the hub. Javaprop stores it as a boundary representation brep and you can convert it in fusion to a kind of spline object or a mesh, but it does not help.

I think there is one option in MODIFY in javaprop to set the trailing edge thickness. Try setting it to 0.

I have still doubts if javaprop is able to generate the correct geometry, because its printing in cartesian coordinate looking like an airplane making linear movement, but it has to go in circle. It cannot produce an interface to the hub, just mess in this region. The output has not much to do with commercially sold propellers, question is, who is right? Commercially might be good but somehow outdated, while javaprop might not be optimized for water propeller design.

To make it worth printing my own props, there should be a better design and analysis available.

I use the aluminium prop gobbla tested, thank you gobbla! I trimmed the diameter down to 17cm on a lathe and use it in a duct. It needs lots of torque most motors cannot provide without a reduction gear. I think the diameter can be reduced further. I just asked Bruno from Alien if he can provide a 6384 with less kv, he agreed.

So, which kv would fit your needs best? At which velo do you want to end with 12s?

Is anyone keen on learning how to make such an outrunner waterproof? Shall i set up a new thread about this?

Yes, would be very intersting to learn how you make them waterproof.

We were drawing 98A from the looks of it, but the amp meter started flashing and we couldn’t tell for sure. Something is up with that expensive amp meter worth $7.99… not sure why

We just ordered the Eagle Tree eLogger with digital screen and accessories for proper inline Volts/Amps, Motor RPM, and GPS speed w/ mapping.

FYI HobbyKing has the complete Eagle Tree line of products saving $51 from regular retail prices the parts we just ordered:

Sascha, thanks very much for the walkthrough of JavaProp. You are ahead of me in the actual CAD work but I did notice that your parameter for water Kinematic Viscosity is off … should be around 1.5x10-6 (i.e. you are missing a zero). Not sure what difference that would make. This is a great program and I hope we can collectively learn how to leverage it better…

Hi Moggleuk,

thank you for your hint! I corrected it in my settings. Fortunately it didn’t make much of a difference.  I’m a bit lost how to fix my problems regarding the further CAD design process. I’ve read in other forums, that more experienced makers managed to design and 3d print or CNC mill marine propellers with JavaProp, so it should be possible. So let’s keep digging into this.

I’m a bit lost how to fix my problems regarding the further CAD design process. I’ve read in other forums, that more experienced makers managed to design and 3d print or CNC mill marine propellers with JavaProp, so it should be possible. So let’s keep digging into this.

Cheers,

Sascha