I use dielectric grease between the plastic and lcd screen. Helps keep water out of there.

The Cnlinko LP16 connectors are a great alternative to the expensive amphenol connectors for a quick connect plug.

But it’s pretty big and 8AWG cable won’t fit tight in the cable gland.

I’m now trying to modify the LP12 for 8mm bullets. However 8AWG would be the biggest cable size it could fit.

If it works out I will show you the results.

Here is a quick size comparison between the LP16 and the LP12

I see you also used some type of aviation plug (the blue one at the left side of your battery pack).

Do you think this type could work too with 8mm bullets inside?

In addition I’m still looking for a quick connect for a water inlet. Not sure what to use there.

I am using this:

https://es.aliexpress.com/item/1005001366346796.html?spm=a2g0o.cart.0.0.28713c00N5kZSC&mp=1

I choosed DN7. One part goes to the wall.

Regards,

Pablo

Ahh cool. Can you send a picture on how you installed it in your box?

As I understand it, the hose barb is sticking out.

A flush mount would be really cool

Hi mate, very nice project!!! Clean work and great looking board at the end  The mast plate seal with o-ring is interesting. Still waterproof ?

The mast plate seal with o-ring is interesting. Still waterproof ?

Any kill switch on this board ? ( maybe I missed this part)

What is the black stuff connected to the receiver ? A switch to cut the signal ?

Thanks Henry,

Well I use my board a few times, not too much to say everything is perfect. O rings works well at the moment.

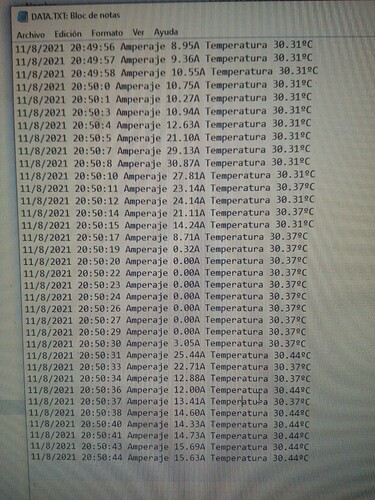

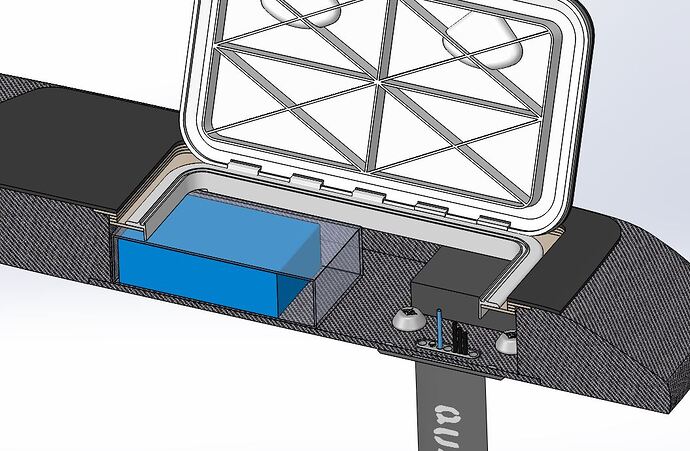

The system in the picture is old. I made big changes and add some sensors. But it is the same concept. Yes, the black stuff is a switch to cut signal.

Thanks! does the motor stop instantaneously when the signal from the receiver is cut with your kill switch ? I am planning to turn off the power supply using a Kilovac and a magnetic kill switch as found on the forum but it is a much more expensive solution. Enjoy your rides!!! ( once the summer will be back  )

)

My system now is:

Maytech motor 120kV

Maytech receiver and transmitter

ECS Flier Boat 300A

Motor stop a few seconds after signal is lost. Start Power about 80-90% (Less works bad). I cant find a good setup.I can ride but it is difficult to start.

If you remove the duct and replace the propeller with a smaler, more efficient one (milled aluminium diameter 150mm with 6” pitch), it will work better. There are several sources for propellers, you find them in the forum.

Also, the prop (probably a Yamaha 7 1/2 x 7 BA) you used is one of the worst of all. It’s nice and metallic at first glance, but otherwise completely unsuitable for e-foil. I write this here, and not just me, over and over again. From a hydrodynamic point of view, everything is wrong with the propeller (for e-foil) - too large diameter (19 cm), wrong blade shape, hub with a minor flaw and probably a slotted hole. Perhaps it is only suitable as a test propeller, something like the version 0.1 propeller, but only if it is ground down to a smaller diameter, e.g. 14 cm (or 13.5 cm).

For your very successful board (https://efoil.builders/uploads/default/optimized/2X/1/1b85cb75dec460cbcb4365752b5f105c9113eb35_2_999x750.jpeg) you should use only the best propeller!

I think diameter is not my problem. Also for safety need duct. I think my problem is to find a good match ESC/Motor, good setup or firmware. But I will try what you suggest. Thanks.

You must a smaller Diameter with your Setup, that is correct.

Print your Prop self, is better

So try that as a first step. For this first step you don’t need to reduce the propeller diameter because the propeller “… is only suitable as a test propeller” for ESC, motor, current protectors etc. And only as a second step (or last step) start to reduce the propeller, preferably gradually, in 5 mm increments. However, to detect changes (if there is an improvement or deterioration) you will need some kind of data recorder or VESC …and then finally get a proper propeller, maybe even a wing. What kind of wing do you have?

Sorry but your theories do not help a lot. There are so may proven setups with this motor, no need to test tons of propellers. Even a printed one with 150mm diameter and 6” pitch will work better than the outbord prop.

Of coarse the esc needs to be able to handle the motor but that is somthing different. The 65161 120kv does not have enough torque for the big propeller, that is why it is hard to get out of the water. It looks like it is the motor with the special shaft to match the outboard propeller, so the commercial aluminium props for 12mm shaft with M8 thread won’t fit out of the box. Best would be to adapt one to 3d print. Another option would be to adapt the shaft of the motor but for that you need lathe. Standard for direct drive propellers seems to be for 12mm shaft with M8.

Hi, nice build I envy you  .

.

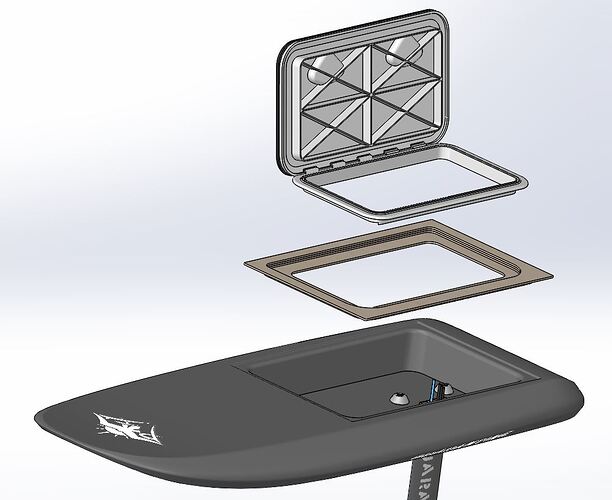

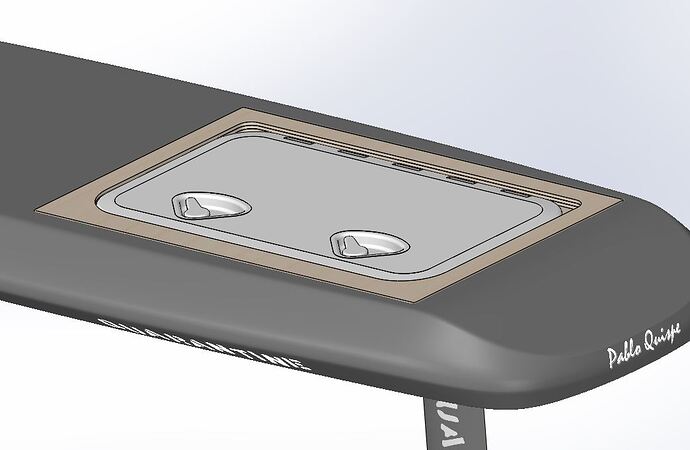

How do you attach the hatch to the foam of the board ?

I adopted this technique :

The wood will be in the foam and under the fiberglass.

Thank you !

Your technique is good!. I made a plywood frame to attach the hatch. I use it because with that hatch I wanted more space in the compartment.

Can you share your pod files once more please?

Thanks,