Does anyone know if the Maytech WPC (waterproofed with ceramic bearings) require additional treatment?

So I am starting my project and I am going to get this kit as a start - I think it will help me do less mistakes as a first timer (although I used to build drones in the past)

I prone surf and I wing surf,

I am building a Foil Drive like project and I need you comments on this KIT which is promoted be Maytech and Michobby

i surf a 33L board with F-one SK8 1050 foil - Plan to to fly to the wave and then take the wave and fly back with motor assist.

I NEED comments blessings/rejections from the experienced here in this forum

My final goal is to build a box that will sit between the MAST and the board just like foil drive did. only missing part technically is how to get reception on the receiver - I can of course take a small antena out from the box, but not sure if it will work from beneath - would love to hear opinions

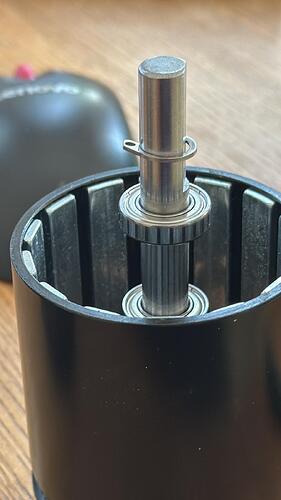

Hi Tamiroquai, Starting Faux Foil drive myself and have similar questions. Does this motor come with ceramic bearings or will you add that on separately?

there are 2 version from what I was able to see, one with stainless steal bearing and one with ceramic.

I will dig more and update.

Let me know what ya think as well

Any saftey tips regarding batteries as well?

It has s thin low-quality coating.

Serious builders like @hangloose can show how its done prperly. Many use brush with heated or thinned epoxy.

For a pragmatic prototype, high-temp automotive spraypaint, corrosionX or some high temp marine grease have been used also. Try the search function?

Hi,

I’d do yourself a favour and read all the previous threads on this subject. All your questions are likely to be answered there. There are some excellent builds logged on this forum and some real skill so take advantage of it…its alot of research but then thats what it takes to get a decent build.

K

So, here is an update, after some planning research, i decided to pretty much base my build on @hangloose 's post which is amazing.

I am riding a 33L KT with f-one sk8 1050 foil, and my plan is to just use motor as assist to get up on foil and ride flat waves far from coast.

Here are the material and parts I am using:

- 6384 no brand motor from aliexpress - will be sealed with thermal epoxy

- flycolor 150A controller

- Daly BMS for charging only - at the moment

- initial enclosure - CamdenBoss CHDX8-322C X8 Series Hinged ABS Transparent Lid 260x110x100 IP66/67

- self printed mast adaptor for f-one alu mast - design will be shared

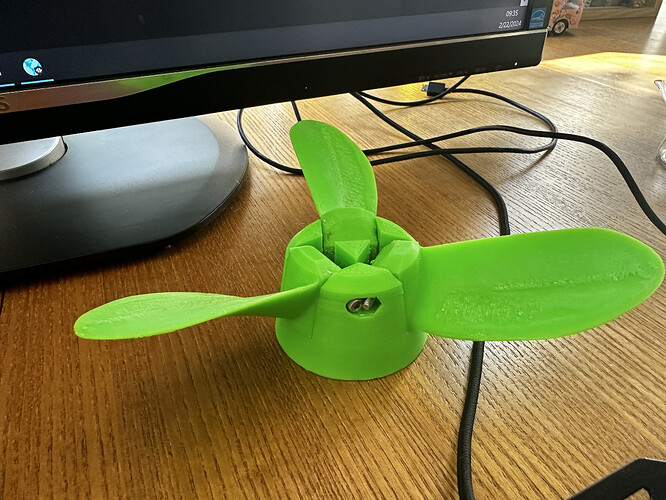

- self printed folding prop 3 blased - taken from @hangloose 's posts

- Maytech remote

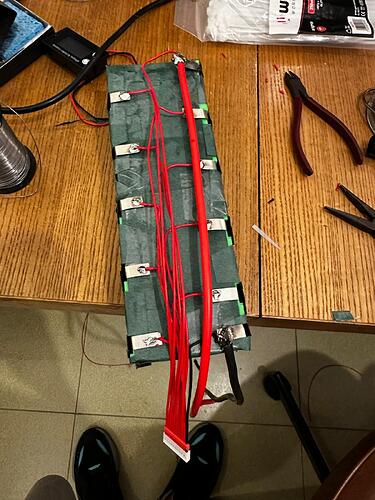

- 10s2p self built battery

- 10 awg wires

- 10awg 3 core cable

- anti spark connectors

plan:

stage 1:

external connectors, cable goes from motor directly to box

test it understand if battery needs to change

stage 2:

build waterproof alu enclosure to be connected under the board above mast

And I am happy to share the mast adaptor that I designed based on idea from @hangloose

Files can be downloaded in thingiverse: F-one Foil aluminum mast adaptor for motor by tamiroquai - Thingiverse

Thanks! did it work BTW?

many are telling me that I need something that gets pressed on the mast.

Mine was printed in tpu. 10+ sessions, zero movement.

@hangloose

What thickness is you battery nickels?

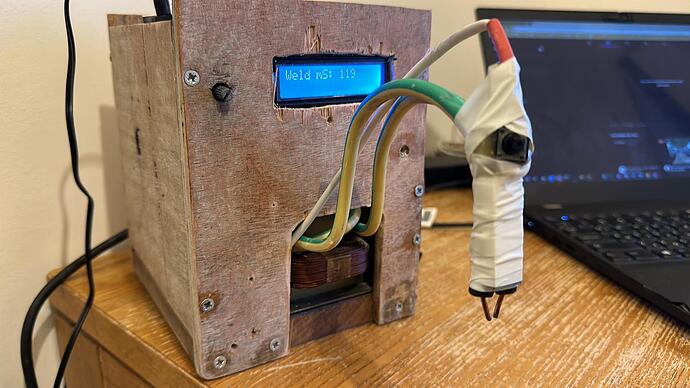

I built a apot welder from a microwave tranaformer. I am able to weld thin nickels but not 0.2

0.2 pure Nickel with my welder

HI @Tamiroquai can you point me to the .stl for the folding 3 bladed prop? Your print look really good, PETG ?

I beleieve it is on printables. In hangloose share

Hi, BTW, if you didn’t find still, I just saw it is on @hangloose, google drive

https://drive.google.com/drive/folders/1-KTznIHZ19NRtmu3c3iP2X_9P2GfM0ES

OK, time to update.

So after bad experience with AliExpress pen spot welder which died (battery overdrain) as soon as I tried welding thicker nickel, I decided to build my own welder using microwave transformer with secondary coil changed to thick wire with just couple rounds, took some improvements to get it to weld 0.2 and 0.3 nickel (got rid of terminal that i used for connection and changed wire to 4awg) - the whole thing is controller with arduino and a relay controlling the high voltage side of the transformer - worked out pretty well, getting good solid welds.

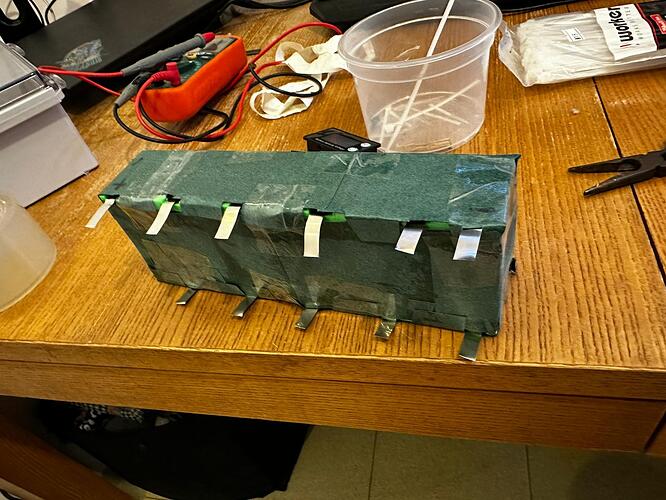

so Battery done - 10s2p at this stage.

so assembled everything and did first power on of electronics - works pretty good!

BTW: recommendation - if you get the aliexpress 6384 motor, do’nt try to remove the rotor plate, at least on one motor, it was partialy ruined as glue pulled some coil wires.

adding some pics of motor sealing, battery and first connectivity

experiment