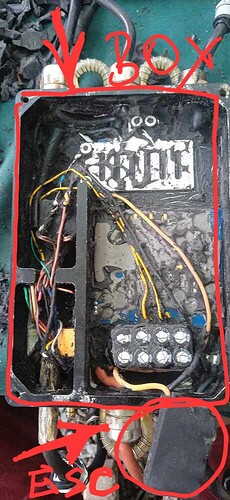

Hello friends, I’m taking the liberty to repost because I didn’t receive any responses on my previous post, and there have been developments in my troubleshooting. My motor wasn’t driving the propeller normally; there were strange noises and occasional direction reversals (I posted a video). You suspected a phase problem or an issue with the ESC (perhaps the internal magnets of the motor rotor). I was convinced the motor was dead because when I opened it, there were a few drops of water. So, I bought a new motor because I’m eager to get back on the water. Nevertheless, I took my motor to a “specialist” (I live in Thailand, and specialists are just skilled handymen who learned on the job), and he said everything was fine. He reassembled and sealed it with silicone. After checking all the cables and the motor, I concluded that it was the ESC. The prices scared me, so I decided to remove all the sealant. Now the work looks cleaner than in the photos. I noticed that a capacitor had leaked; today, I’ll work on removing the boards and giving them to an electronics “specialist.” If you have any advice or maybe some good tips for repairing or improving all this (simple solutions), I’m all ears… For your information, I’m using a Maytech V3 remote control.

You could have continued in the old thread I think, then later it’s easier to see the steps taken

Anyway here at least the link to the old topic

https://foil.zone/t/need-help-for-find-the-problem-of-my-e-foil-im-beginner/

Looks like there was water intrusion?

Anyway, I can’t see much of the actual PCBs on the images, so hard to say what’s damaged

Leaking caps can happen over time, best to replace all of them then

Or just switch to a new ESC, Flipsky 75200 waterproof for example… Or 75200 not waterproof in a Alu Box of your own

I will follow up what the guy will find on the PCB. Will the ESC flipsky work with my maytech remote control? Thanks for your answer

You can try repair that mess, but it would probably make more sense to buy a better esc. The maytech “ready” made solutions are messy and actually not that good at all. The DIY crowd tend to stay well away from them.

Ludwig has given two good options. There are other escs and vescs that will work too, but it also depends on your DIY capabilities.

I want something relatively simple if I could avoid to connect to computer it would be a must.

While connecting to a computer for initial setup may seem complicated, it will give you better diagnostic and tuning options in the long run.

You may watch my video to see what you’ll have to do

LINK

The remote will work with this (any) VESC

ok thank you, I’m goind to watch it now.

Would this work? It’s half the price… They’re the same references as Flipsky; at first, I didn’t even realize it was a different brand.

That looks like a Makerbase version of the 75200. You can search the forum for “makerbase” and see what people have experienced. I know they have been used.

Just note that this is the version without water cooling and you currently have a water cooled setup. A water cooled version would be a simpler replacement.

You could still make this work if you have it installed inside an aluminum box as Ludwig mentioned above. Maybe use the existing water cooling lines to attached a chiller plate to the outside of that box.

From what I’ve seen the makerbase have a problem with the quality of casing (not being even) and therefore internally the PCB is not making good thermal contact to the case…

So if you get that you will need to open it and maybe add thermal compound or something

But if you put it into a Alu Case / on a cooling block anyway you can just get rid of that original case

Wow, that looks really poor!

I don’t understand why workers in the factory can’t do it properly. That’s weird; there’s nothing difficult about applying thermal paste everywhere. Thermal paste is silicone, right? I’m a bit confused because my PCB was covered by a grey material like silicone, but I haven’t yet checked the contact with the case. I know thermal paste for CPUs shouldn’t dry, but what I observed is that the grey covering on my PCB is dried and looks like silicone.Thanks for the update.

Thermal paste is silicone, right?

No, there are a million different compounds, thermal grease, thermal epoxy, thermal silicones etc.

Most often they are a base material, filled with thermal conducting compunds.

Pure silicone rubber is actually not a good thermal transfer material (without the needed fillers), but it is a rubber that has good resistance to high temperatures.

then what is the grey paste on the on the last picture? Is it same paste covering my pcb on my first picture?

I bought it: ซิลิโคนระบายความร้อนCPU ซิลิโคนCPU ซีพียูระบายความร้อนซิลิโคน 30g/หลอด ควบคุมปริมาณซิลิกอนได้อย่างแม่นยำ | Lazada.co.th

Sorry i stay in thailand so we use Lazada. If you can share the right product to buy please?

Before you buy anything else maybe it would make sense to waterproof test your board. From what I understand you bought a used rig and used it several times BEFORE it stopped working properly.

Take the board and seal it up and put it in the water and jump all over it getting it submerged if possible. FIX the leak if you have one before moving on. ![]()

You mean the electric case where stay my battery and ESC? I alsways have a little bit water in it. Thought is wasn’t bad. The ESC was dry when i pulled out all of silicon. The professional said my PCB is dead. I don’t believe him but that’s ok, i will buy a new ESC. https://th.aliexpress.com/item/1005004698561517.html?spm=a2g0o.productlist.main.1.5b9b5GbX5GbXSe&algo_pvid=3d20f2bc-0ded-4b5e-b146-277e1ec59575&utparam-url=scene%3Asearch|query_from%3A

Do I need only this? Do you have a link how to waterproofing it?

Thanks

or perhaps that one is more clever to buy : Flipsky 75200 84V High Current With Aluminum PCB Based on VESC For Fig – FLIPSKY

Some photos of what you refer to as electric case and perhaps the entire board would help.

Any water especially salt water that is corrosive is not good if it can touch your battery, wire connections, VESC etc.