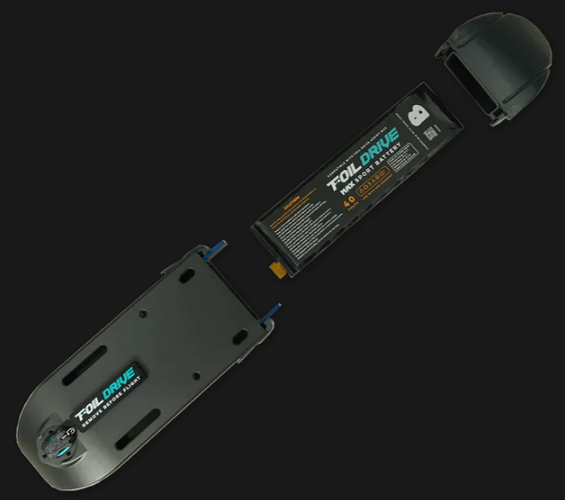

Thanks - my main issue with this torpedo design is making the protruding battery pod strong enough to withstand being kicked when you fall off (on a wave) - its a real possibility - and the leverage is probably too much without significant engineering. But I do like this design for hydrodynamics and having all components in one unit and cooling etc.

This is a cam lever/lock:

When you push the lever down it pulls on the bolt and locks into place. If you had 2 or 4 of these longitudinally (along the sides of the mast) to clamp the battery pod on.

I will have to mock up a few examples (3d print) to test for strength.

The other design - underboard (FD#2) - also has waterproofing issues to solve. But could get away with a simple 3D printed shell and aluminium supports where the screws attach mast to board (could potentially stop 3D print before top layer and insert aluminium plate, then continue printing top layer. Hydrodynamically, rounded edges are much better than square.

The more I look at the FD#2 the more I like about it.

Any idea if the battery connectors (and the BMS cable) can get wet - or is that bad news? Looking at the photo - I guess it;s possible to make the cover pod mostly waterproof - clicking/screwing into place and having a rubber seal.

In fact… could you not have the motor mounted to this or does it need some depth?