Exactly. “Thrust over Amps” tells you absolutely nothing.

If you just lower a random propellers pitch you’ll already getting better numbers there.

Right! This is what i mean. For the user only thing that matters is the ”power needed”@“speed x”

Since propeller efficiency is what it is, one optimum pitch for one speed you can easily skew the numbers by comparing apples and pears. I’ve seen this done extensively in boat propeller advertising.

If you instead provide power curves from zero to x m/s in the same conditions then the results can be objectively compared.

As much as I would like to see a prop like this become suitable for the efoil community this vendor seems kind of sketchy.

The website lists minimal documentation on a relatively expensive part. No other products on the site other than some board “trailers”. No business address or phone number listed. No refund on the “beta” product etc. makes me skeptical on whether this product is even worth trying.

Safe until you get a finger or toe in the curve and then it’s goodbye body part. Also that prop looks terrible!

This cannot happen in a situation where the prop is rotating because the limb is ejected. This makes the toroidal prop less dangerous than a rotating folding prop. Cuts with folding props haven’t been reported yet whereas the risk exists.

At rest the situation you describe means 1-inserting your toe or finger in a loop blade 2-pull the trigger

This is not impossible but rather improbable

If you fall into the direction the prop is spinning, it is entirely possible to get a finger or toe into the prop.

This deserves to be tested

With industrial machines during initial safety testing I’ve seen people use carrots so simulate a finger…if it breaks a carrot, it will break a finger.

A really informative video comparing different quality prop styles, materials (no FDM but PA12) and surface finishes where two efoil 65161 motors are used to power the boat…

No, it won’t. Carrots obviously don’t have skin and bone, and ligaments are really strong. I’ve been crack climbing for some 20 years and when those feet slip and your fingerlock is secure you get to test how solid the human body actually is. It’s unbelievably strong.

I think a propeller bruise is totally acceptable, but a cut off finger is not, probably most plastic propellers are ok in this regard - but probably not the steel or alu ones.

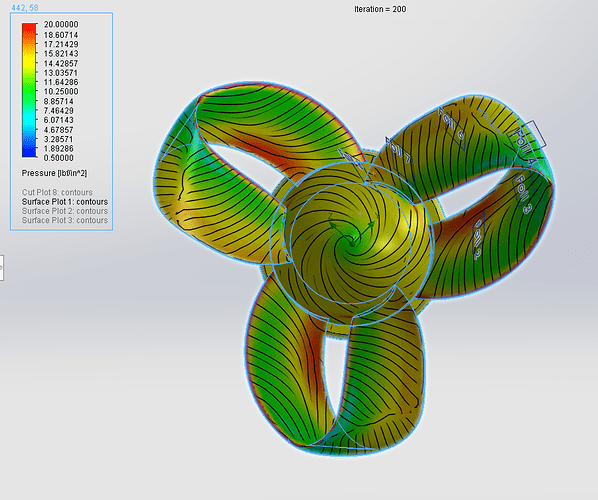

Started playing around with some designs in solidworks a few days ago, turns out it is pretty difficult to get right…

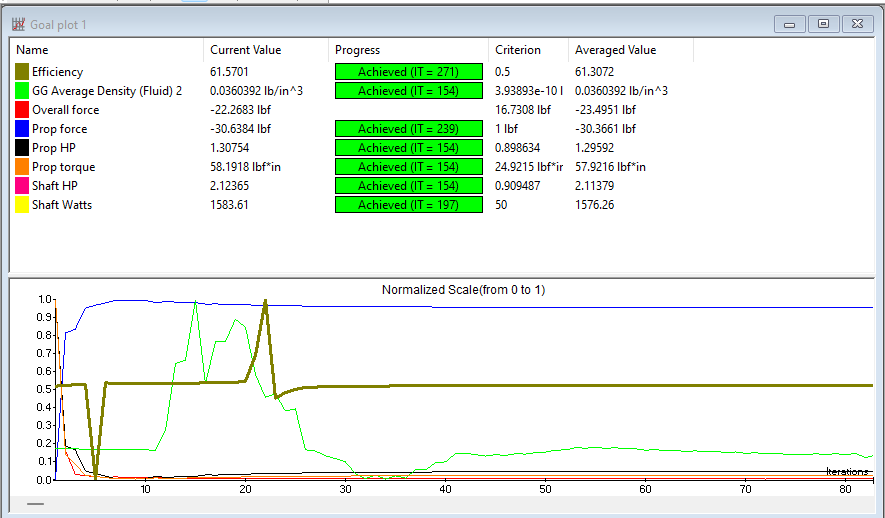

After may iterations I have what I believe should be a 7in pitch equivalent prop. (front blade is 7in pitch, rear is probably closer to 9 because the water begins to spin around the prop after the first blade affecting the angle of attack of the second.)

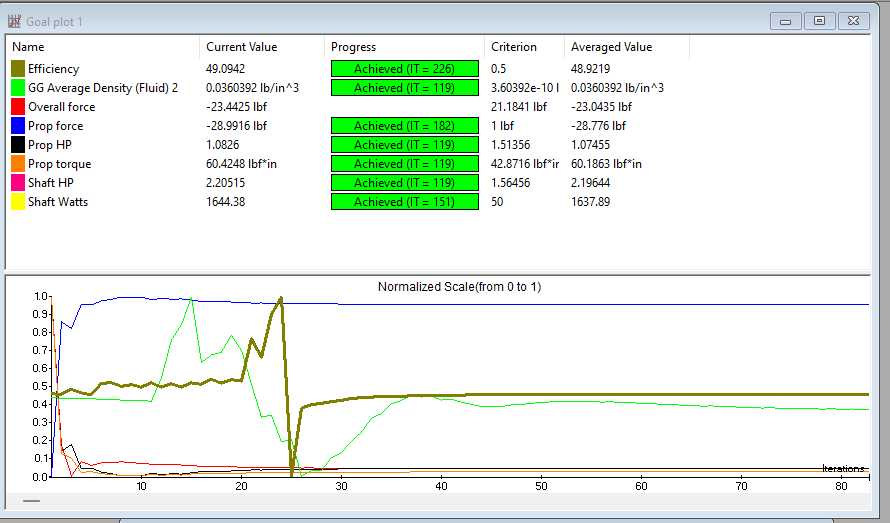

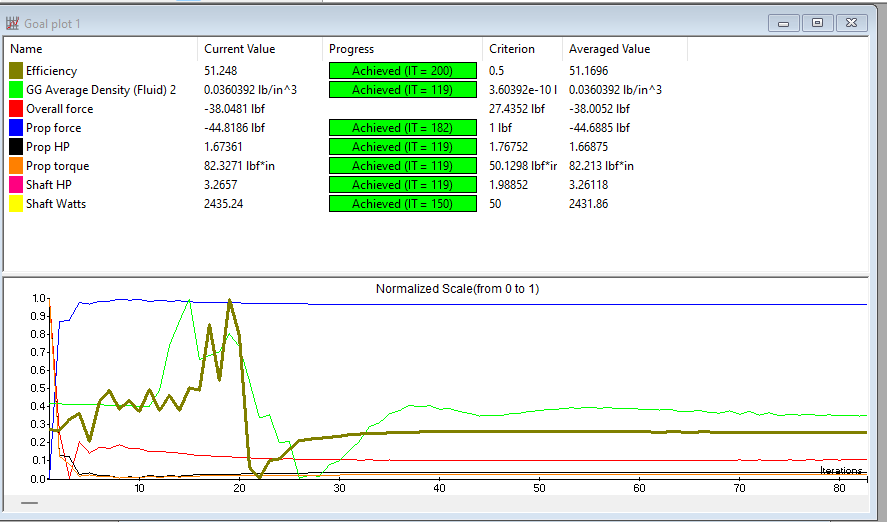

Ignore overall force, I have my motor mount, no wing in the model.

Data at 2300 rpm, 14 mph

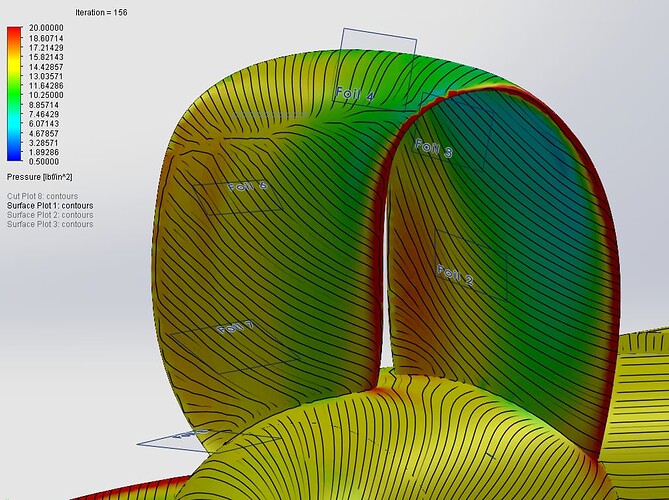

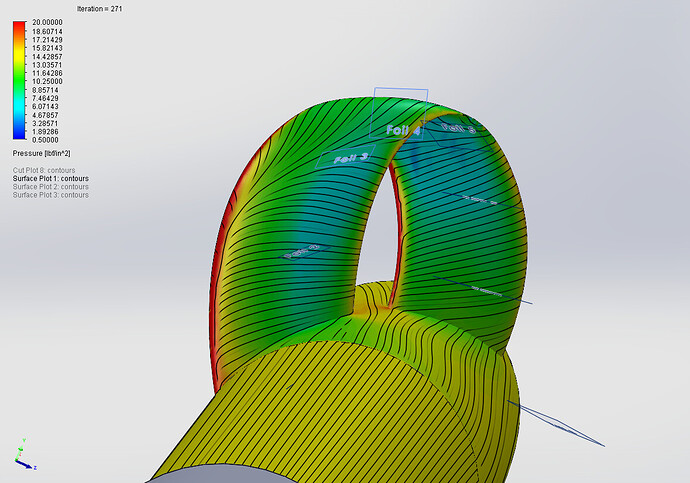

You are getting serious spanwise flow on that lower blade, which is very bad. The red area shows higher pressure which would be working against your thrust. You want to see all the streamlines going with the chord of the prop more like the top section.

I reduced the sweep quite a bit with little change, any suggestions?

My hope is to get a decent blade shape with help from everyone here that I can then share with everyone to adapt to there own driveline.

There is realistically little to no way a propeller of this size can exceed 70% efficiency (assuming 150-160mm diameter & 3-4k shaft speed). I can say with 100% certitude the best non-toroidal props within this range wouldn’t exceed 60-65% efficiency. Getting to this / these designs is not easy / cheap. And I’m assuming it’s even more complicated for toroidal props.

I know someone with tens of millions dollars spent in R&D for years in his really famous company that couldn’t increase more than 0.5% his efficiency design in almost 2 decades.

Got a little help from some people that know more than me. Still tweaking, hoping to try one out soon!

Not sure how many guys have seen this:

Guys are now buying and testing it on their lift boards.

Jeezus, that’s a hefty price tag.