I’ve just swapped mine over. I’m sure I had them going outwards before and it felt more stable and turned better and less to none torque roll

Hello,

Propellers spinning direction, I’ve always used outwards motion. Better for moving air bubbles outside than sending to the other propeller and better for stability.

About this air bubbles, I would say it is the last main issue I experience. Comparing dinghy tow to my best friend Zerotow, it is night and day. He is able to take off with headwind and when Zerotow bounces in the chop, the Manta propeller never ventilates.

Whereas when the dinghy tow starts to do little jumps in the chop or when I try to start with headwind, I see a lot of air bubbles coming from the back and I often loose line tension . It’s annoying to be honnest !!!

It’s very hard to determinate the cause of this air bubbles. Too short masts ? Air coming from forward because of the hull shape ? Bad propeller design ? Too short distance between mast and blades ?

Something obvious between our respective propellers, design is very different. Manta propeller is lower aspect ratio and has more surface than mine.

It may handle more load on the blades than mine which may saturate at high load.

Any ideas or same experience ?

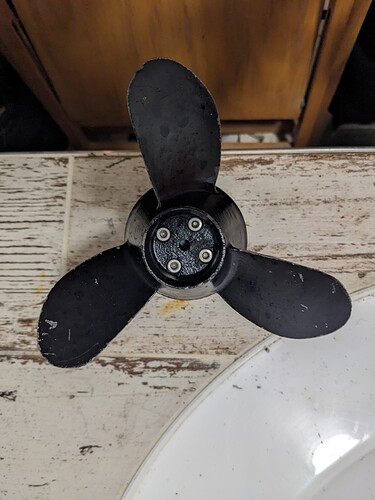

For what it is worth, my first attempt at the tow boogie had a fixed 3 blade propeller. It looks like the same as yours. I had lots of ventilation. I then changed them to a 3 blade folding prop printed in aluminium via craftcloud that are close the the genuine foil drive ones and I got far less ventilation. Run time was also greatly improved.

Dinghy tow looks fairly short no? Compared to zerotow that’s about 130cm long. That and shorter mast and the hull shape I can imagine when dinghy jumps on chop makes it worse

Saif Seas: A remote rescue craft, with some iterations on their website. Underpowered, but relevant.

RTM (roto moulded), more on the price than anything (€500) , but it looks like it could be adapted.

Adding to this thread as something I keep coming back to as quite interesting, as my primary issue with boogie was cavitation.

Something to look at is surfacing piercing propellers, where the propeller is always ventilated. I don’t necessarily believe it is the correct answer, but it is quite interesting.

It is relevant in two places:

-

Offshore powerboat racing

-

Solar circumnavigation

What is peculiar to me is that these are the two extreme opposite ends of the spectrum, with different power curves, different energy sources, and different speed ranges, and yet both ended up with this related design.

Last mentioned here

Definitely a big difference in stability in running outwards and steers better tried with a 40l board with me at 95kg and easily pulled me out. I will buy the Armstrong tow rope though this one I have has no stretch and pulls arms out of sockets. Tried the new MK2 MA890 and absolutely love it smooth and carves great. Need to work on my technique with sinking board I couldn’t sink board. What technique are you guys using?

As for ventilation Im not noticing it. But ion the big choppy day it was launching off the waves into wind breaching props a bit but not a big issue

Is there anywhere I can buy these Ali blades from? But they may not suit these 6579motors

Setup rubber flaps like Zerotow V2, great improvement in term of sailing behaviour in the chop, jumps and take off

Is it on both sides? What is the rubber flaps helping with, push nose down at takeoff?

Yes on both sides, it helps pushing the nose down on take off, at speed, when the boogie jumps it stays more horizontal.

Ah very interesting. makes alot of sense. In a way its like interceptors they use on speedboats.

Hi everyone,

Lately I swapped my fixed 3 blades alu propeller from Volker to FD clones.

Big improvement felt in term of ventilation, flat trim sailing. I can take off with headwind now without any ventilation. No more issue when the tow lands on water after a jump because they have a very good and quick grip.

It’s just less fast and empties the battery a bit quicker.

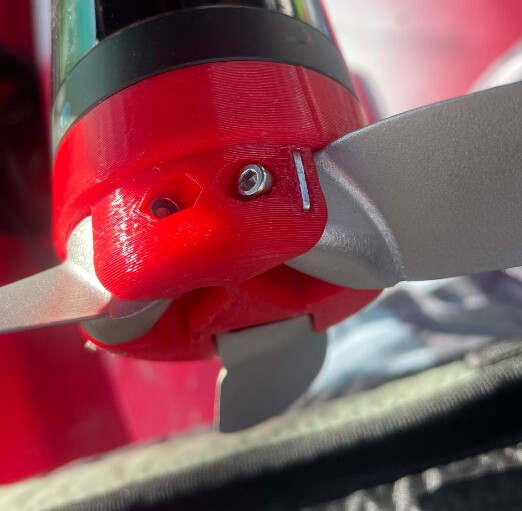

Even moving from 2 blade to 3 blade PETG hub made a big difference for me. Did you move from 2 blade or 3 blade Volker prop? I have a set of 6 of these blades but having trouble with the hubs cracking when printed with PETG (no surprise really). Are your hubs surviving? What material and method did you use for the hubs?

Glad it worked out. I had exactly the same experience.

Mine also cracked with polycarbonate. I lost two of the three aluminium props. The weak spot is the relatively thin wall where the screw goes in. I’ve just printed a set with PET-CF to try and will then try PPA-CF. Ultimately though, I think we need to redesign the hub to have a slightly thicker wall where the screw goes in. I just haven’t had the time.

Agree it needs thicker walls, I have a friend who is going to redesign the hub as he is also using it for foil assist and has better CAD skills than me. He did solve it in the short term though by melting a staple into the weak area ![]()

would you be able to send me the files for these props ?

A simple fix is to do it like Mantafoils and have it split at the base and screw on the three (now). failing pieces to the base.

That way you could print it in the right direction and there would be no more problems.

On the other hand, I have not had any failing.

Printed in PC with no cooling.

Any addition of CF will only weaken layer adhesion and make the problem worse.

I first moved from 2 blades to 3 blades fixed aluminium Volker prop and then moved to FD clones prop which are the best for sure in term of behaviour.

I have no printer at home so always MJF PA12 for hubs. Never had any issue.