Of course, printing is easier, but, for example, I had a couple of PETG parts that just fell apart after a year. I started to figure out the reason and found out that the structural strength of PETG can be greatly reduced by vibrations.

One of the reasons why I want to go back to a single-motor scheme is that I have a couple of unused boards ). I do not plan to use the StrongArm scheme with a linear actuator - it is good for a commercial device, but for a personal one it is too complicated, since it requires an expensive remote control with an additional channel.

My friend has an 18 kW tow boogie based on a water jet. It is perfectly controllable, waves are not scary for it, automatic modes such as “follow me” are implemented. But there is one nuance - its weight and dimensions are close to a boat.

I hope the incident is closed.

If anything, I have no complaints against Jesserosco, only gratitude for the excellent topic. I would have preferred not to mention my authorship at all, if not for the accusations of trolling.

I wish everyone a fast tow boogie and the latest GoPro models!

We’re on it!

20 characters…

rctestflight on Youtube has decided he wants to learn to pump foil and put out a nice video of developing a tow boat.

Not exactly a tow boogie, more of a tow catamaran. I think he needs a Bremote to get the differential steering set up.

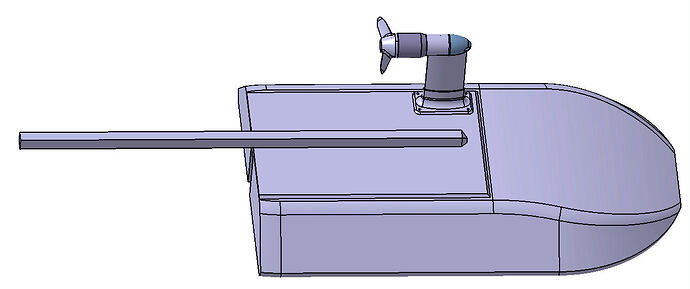

What do you guys think about having the tow bar under the board, doubling as a fin/keel?

Sort of an extension of what @Strongarm did here:

If it works well and provides better straight tracking then you could lower the fixing point and have a sliding tow bar inside the keel. Like this:

Any views on this?

I tried a sub surface tow point so it was like a combination skeg and a tow point.

Initially it was 100mm below the water, and I kept cutting it shorter and moving up the tow point. I didn’t notice any real handling performance increase by having it lower but the rope coming out of the water and the associated spray looked like crap.

What you have drawn will work fine though and will help with the tracking.

OK, thanks for the input. The spray issue i wouldn’t have thought about. I’ll keep a small keel and put the tow point above water ![]()

With two motors you will have no problem with straight line movement.

Hey everyone - I’ve read a lot and have more to do, but have a few burning questions.

-

I have an old hated 90L wingboard (5foot4, 27" wide, 5kg). Is there any reason i couldnt use this as the foundation for the tow boogie? I assume people dont do this because of cost. The advantage I feel could be stability and lack of mess in construction (can mount dual motors to existing mast track with some 3d printed parts, footstrap holes near nose for securing box etc).

-

Can someone guess/propose a battery spec that I can ask a local maker for a quote to get an indication of costs? I am unsure what size people here are running. I would want 1hr to 2hr of use in waves … a lot of launches (30L or 55L board) and not much tow cruising.

-

Are there any new ESC / motor combo (2x, dual motor) that people recommend if they were starting afresh? I am starting from blank slate.

Cheers!

I personally run 12s12p. I have one with P42’s and one with p45’s and go over 2 hours launching with a 27L board. I also have a 12s8p that I can get about an 1 to 1 1/2 hours on. I use 12s because that’s the most voltage the flycolor x-cross speed controllers I use can take and they fit the pelican 1450 case nicely though you could probably get a 14s12p to fit if you wanted to use a different speed controller.

What Motors and props are shown? Thanks.

New version with a 48 boogie,.Flipsky 6384 motors and longer masts. The tow bar is clearly too short, the boogie flyes above the water and looses trust as soon I ramp up, impossible to take offin this config.

Turning is 100% more efficient than my previous 4’6 Kid surf version . It turns on a dime.

I hope I’ll manage to calm the nose up with a longer bar ![]()

I like the little flag, will be using one too. Did you extend the antenna to the flagpole? If so, how did you do it, original antenna and an extension wire? It’d be great if you could link the parts you used.

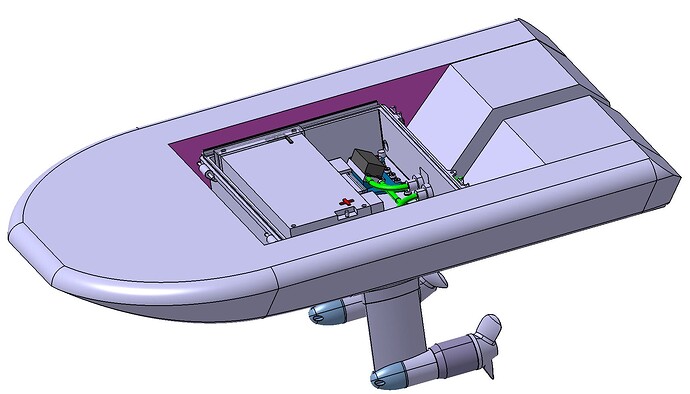

I’m close to starting the build phase on my tow, routing of the electrics and cooling is finished ![]()

How long did you make the masts now? And would you be able to share the flipsky 6384 propeller file? thank you!

It’s 25 cm now and the propellers files were modified by a professional to fit to the Flipsky motors, he didn’t give me the file.

I showed my son a YouTube video of a tow boogie last night and it looks like I need to make one now. Can anyone point me to a post that has a list of all the necessary parts? I looked but couldn’t find one very readily. I will read through everything more thoroughly this weekend , but I just want to see everything I may need all in one place. I will build a plywood shell/board, but I would be hoping to buy and not 3d print the other parts. But if I have to I can 3d print smaller parts.

I’m a long time follower-first time Builder and slowly putting my Boogie together. I don’t have much electronics experience either but I really love foiling and don’t want to pay ‘off the shelf’ price to get one as I’m not quite the right demographic for that ![]() I do love how the Zerotow has follow mode though. I think you’ll struggle to buy some of the parts needed and you’re better off buying a 3D printer, as so many awesome designs on this site cannot be purchased, only printed yourself. As far as a complete list goes, this site does have a few lists, but they’re usually quickly outdated with new ideas, designs and products. The jDubs Dual Motor build was a great place to start for me. Also the Creality Ender 3 V3 KE is a very well priced and accessible 3D printer for most of the parts you’ll need.

I do love how the Zerotow has follow mode though. I think you’ll struggle to buy some of the parts needed and you’re better off buying a 3D printer, as so many awesome designs on this site cannot be purchased, only printed yourself. As far as a complete list goes, this site does have a few lists, but they’re usually quickly outdated with new ideas, designs and products. The jDubs Dual Motor build was a great place to start for me. Also the Creality Ender 3 V3 KE is a very well priced and accessible 3D printer for most of the parts you’ll need.

What depth do you recommend for the motors? In other words, what is the distance from the bottom of the board to the motor axles?