Also the Bambuu labs A1 printer is fantastic and well.priced…easy software and great qulity prints at high speed… My two cents.

K

That’s a few hours printing time😅

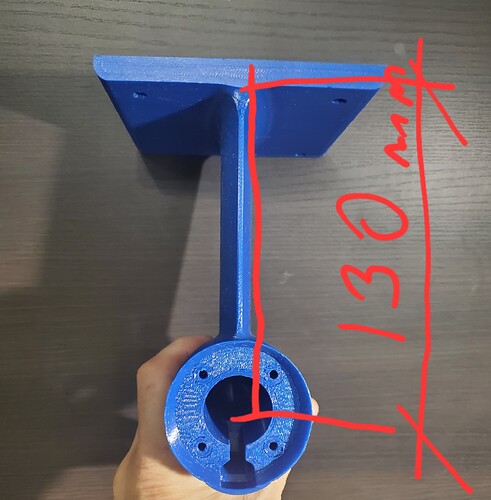

My gong masts are cut to 230mm from the bottom of the board to the propeller center.

It’s good for choppy water but I need to have a long tow bar because of too much nose up when I start.

I’ll try to lower the tow point like 15cm with a short bar to see if it has the same effect.

Are you enjoying this more than your old setup, the 4’6 Wavepower?

It’s not a real game changer I’d say. Both are good in terms of stability.

You say that the strength of printed parts is not sufficient. I completely agree with you. Why not make the most important parts out of metal? For example, the motor bracket can be welded out of stainless steel and printed fairings can be made for it. I could not keep my balance on my electric foil with a homemade wing. So I designed and ordered a stainless steel stand so that I could hold on to it like a scooter handlebar. It was made for me using laser cutting and welding. It turned out to be a very good stand. Surely in your city you can find services for the production of metal structures.

Thanks for the advice. There have already been many metal mast clamp designs with a plastic fairing. As for the scooter handlebar, especially the metal one, I am against them. It is a dangerous and unnecessary element in my opinion. It is better to focus on acquiring a normal wing, this will contribute more to progress.

Agree, i see my teeth being smacked out by that in just a small crash.

Boogie for auto follow filming, is there such a thing?

Sounds simple but think of the compliexity and reliability of follow function of something like a modern DJI drone (Mavic 3 etc) or Skydio

I agree with that. I practiced with the handlebar and have already removed it. I just used it as an example.

There was another reason for using it. i couldn’t get the radio control to work and had to use a wired throttle like on an electric scooter. Now the radio problems are solved.

Has anyone thought of trying to create a water tight inflatable compartment similar to strongarms commercial zero tow? It makes a lot of sense and was a brilliant idea. I can really see why the zero tow has it.

Has anyone thought about a DIY version? I’m sure it would be tricky but might not be impossible……

You can pick up some of the parts needed.

- dry suit zip

- iSUP valve for inflating

- pvc material

- pvc adhesive

There wouldn’t be any need for the drop stitching. It would get in the way and the pressure would be low compared to an I sup.

The seams and the connection to the hard hull of the boogie would need a lot of thought. The hull would need to be solid (not a foam board) to ensure good adhesion.

Thoughts? Worth the effort? I’m ok at shaping and building my own sups and surfboards but the thought of a smaller package when deflated for storage is another big bonus.

After observing my flat board during testing, it seems like a v-shape hull with well shaped bow would be be optimal, essentially a small power boat/jet-ski hull design, that would allow it to ‘lean’ around corners, which has the effect of transferring the battery weight to counter the force that would cause it to flip. The function of the boogie is after-all, more like a boat than board. This is the Takuma design, which has this. Keen to hear about the issues with this, apart from the cost factor it compared to a cheap second hand boogie board.

I don’t think the Takuma etow should be product to model a Boogie off. You want a bit of a V at the front and a bit of a rocker, but the back should be flat.

Once you spend time behind a boogie you will see how it reacts to the inputs from the tow rope. Bing flat means it can slide and turn. A V would encourage grip and then rolling/ capsizing.

.

I’m looking into this too ;).

I was thinking a dropstitch inflatable boogie board hull (I like the idea of a softer hull than something solid - although a soft boogie board wouldn’t be too bad). There are a few companies in China that can make custom dropstitch pretty easy if wanting to go down similar route to Zerotow (battery cutout in dropstitch). Possibly need to put a foam V shape underneath to deal with the flipping issue.

Then I was thinking a large dry bag in top of the hull - wouldn’t be as tidy as a zip but the folding seal might hold low pressure? I’m just trying to find my dry bag to test this… If it works it could deal with self righting and another waterproof layer for a battery.

I’m just starting out - I’ve been using an efoil as a tow boogie in flat choppy water and it works ok, but now I’m wanting to build a dedicated boogie.

Been thinking what else is out there to try, a kids kayak? Spearfishing floats have potential, most have a low bed for keeping battery low, but they may have have a lot of drag as not designed for speed. Anyone tried anything like this? The inflatable ones may just deform as soon as there is any real force on them, but they could be reinforced with a rigid tray connecting battery, motors and tow point…

Maybe one of the bigger RC feeding boats sport fishers use?

What about a hard hull made conventionally wit eps or xps and laminated and then a soft top like the zero tow to give it volume and prevent capsizing?

Could this be something usable?