Look at the Bremote topic, @ludwig_bre answered this question the last days.

Hi. Setup sounds good. Im also building a battery with aliexpress battery holders. Did you any extra insulators on top of each cell or does the plastic cell holder keep the nickel strips aff the negative outer shell when spot welding to the positive terminal?

Better put fishpaper rings on the plus side as an extra safety measure in case the shrink tube breaks. The whole can of a cell is minus, so you can get a short from the nickel strip on the plus side.

Thanks, I will do that.

thanks, is it 20A per bullet which makes it 60A overall

cause the LP 24-25A may give us 3x25A so… 70A overall ?

I also got a pair of LP 20 likes yours. how did you include the MT connectors inside ? epoxy or a custom 3D bespoke part that you epoxy inside ?or is the MT60 completely free flow and you just use the CNLINKO to protect the flow ?

I’ll be coming with 3 motor wires inside the connector so I need to put some epoxy or 3M 5200 to make the connector waterproof on the outside.

Hi everyone,

Just a reminder for BEC’s installation. On a dual tow boogie, we have to focus on good motor reactions because they work as twins. I already have motor power oscillations which are a pain when the boogie zigzag during rides.

To achieve that we need PWM signal + receiver stability

Advice on BEC’s manuals is to set it far from receiver and antenna and in fresh area. Personally I will stick both BEC’s directly on my main cooler.

Is the PPM signal getting interference from the motors etc?

Would using UART rather than PPM not prevent that?

I don’t think so, because the motors are far from PPm wire and under water.

But instead of putting BEC and receiver in the same box like on DIY Foilassist , it would always be better to keep both BEC’s outside the receiver box , cooled if it’s possible, to avoid extra heating of these elements because BEC can be very hot. And cheap BEC’s very very hot ![]()

This extra heat is not good for the system stability IMO and could affect the PPM signal quality or motor desynch. Personally I had motor power oscillations, I believe it came from that.

I’ll see if it improves the system behaviour on next trials.

I don’t know anything about UART.

The BEC (battery eliminator circuit - I hate acronyms) is just running the receiver board isn’t it? It shouldn’t get even warm with such a low current.

It converts 50V to 5V, creating heat to get rid of this excess of energy

It only creates heat based on how much current it uses. It should not get hot at all if it’s only connected to the receiver. There’s another issue somewhere. I’ve used BECs with no heatsinks and they’ve been perfectly fine.

No, should not create any notable heat

In this case the BEC seems to have ultimately malfunctioned, leading 50V directly to the Rx, killing it…

Ok, so guys, simply avoid this BEC ![]()

If it’s not BEC which create this oscillations, I would say it comes from 100deg temp protection.

It reduces power on motor always around after 15 minutes, I have to ease the throttle, push again and it restarts with a different noise.

But I know @Jesserosco system is the same and hasn’t got such issue. Moreover I’m in a colder area than him.

I’m going to hazard a guess that there was a voltage spike and that’s what killed the bec. In turn then it may have shorted out and damaged the receiver.

You also shouldn’t be hitting near 100° at the escs if you have adequate cooling. You definitely need to get the escs heatsinked adequately so that they sit at a maximum of around 50°

something is wrong then, probably getting back fed somehow?

Maybe asking the obvious, but it says “up to 13S”

How many cells do you have in your pack?

I use 2x 6S10P in serie.

I’m planning on putting one of these in my next tow boogie: Go-FOC DV6s - MakerX

I talked to maker-x and according to them it should be able to handle 4000 watts burst and 2000 watts continuous at 42 volts. Wiring should be a lot simpler than using dual ESC and dual BECs. I will mount it on an aluminum plate with water flowing on the opposite side so cooling should be pretty good.

@jenz that’s a brilliant idea ![]() Unfortunately too late for me!

Unfortunately too late for me!

I’m planning the connections for my dual motor tow, i want to have clean connections (which i always find challenging). It easily turns into a rats nest… Basically, i think i need some advice.

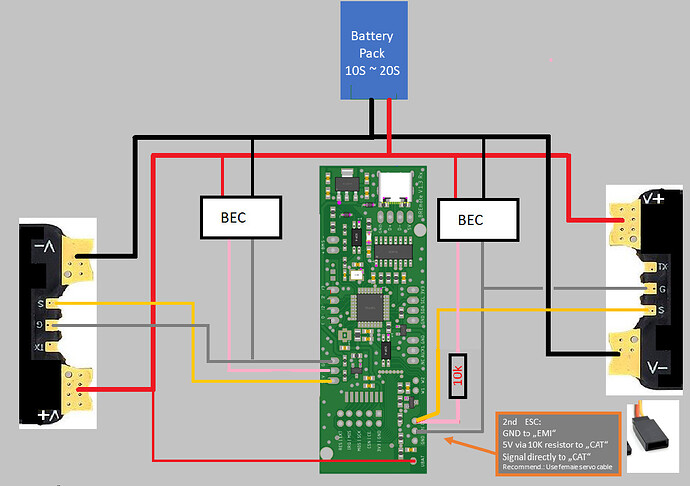

Schematic:

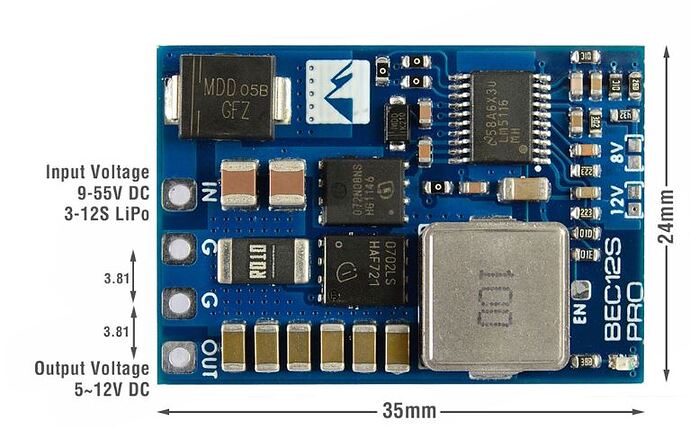

I got the mateksys pro bec which uses a pitch of 3.81mm:

Was thinking about soldering a screw type terminal block on the BEC. Like this (but 4-pin):

Then for the connections to the esc and receiver use a couple of y servo cables, will need to be modifications to the wire on the second esc/non-standard connection side (with the 10k resistor).

What do you think, how would you connect the Rx/BEC/ESC? A custom pcb would be nice but i don’t know (yet) how to do it.