Can’t wait to test them! v_s is so kind to weld them for me! Thanks again it just looks fantastic!

Right I had in head the fuse bus style , so yes double the S where current flows

Board build

I guess i’ll name it Pink Panther

Building the Box:

Bandsaw & joining the Parts

Let the Hotwire fun begin:

Shaping with my special shaping tool

Its my first Monoski, i have learned on, still kept IT, no one knows, what it could be good for.

Gives a nice rough shape:

More wirecutting, and a bit of sanding

Laminating, what a awfull mess

Innards ready to reinforce with glass

The Mastmount ist reinforced with hardwood, and transfers and spreads the force into the Box

Final Resin Layer

Some imperfections, but who Cares?

Lucky me, everything fits inside

The Hatch is 8mm Plywood with one layer 200g glass and a couple screws

First water contact, with jumping around on board, everything is waterproof, no leakage

I’m really liking the look of this! What is that pink material? I will probably end up building my own board. Any information would be greatfully received.

Its just usual XPS, used for thermal insulation (house basement)

125 * 60 * 14cm

You can get them in various thickness, i was looking for 16cm thickness, but i would have to order a whole pack, so i only got the 14

The thickest part of the board ist now 9,5cm

150cm long, 55cm wide.

About 55Liter

80100

The APS got only a slight touch up:

Some magnet gap filling, and a coat of epoxy.

Shaft shortend with angelgrinder on a lathe.

Stator same. One coat with epoxy and shortend the wires.

Bearings will be switched later to open ones

Jump to Bearing drama

Update:

Switched to these beautys:

3 6801 12/21/5mm

1 6809 45/58/7mm

Mastclamp

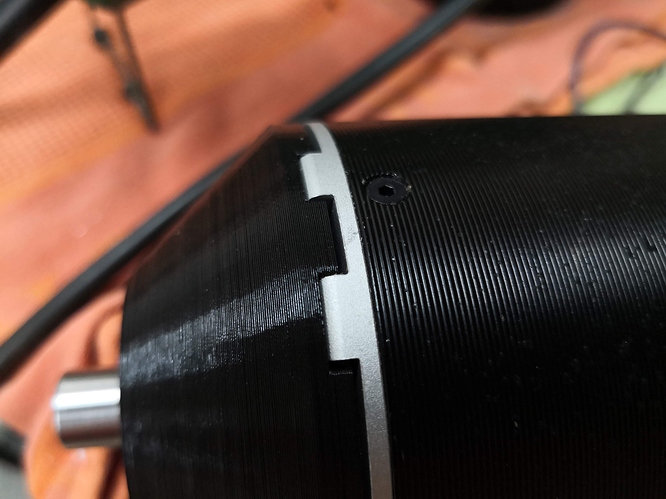

I am happy, that my first print fits Well

Mount 80100 to RL Mast

I used Tinkercad. I designed a unique system, that allows water to flow direct into the mast, so no need of a tube inside the mast.

These files are printable without support:

Very nice design but why a vertical wall only on the right hand side of the front part ? Rigidity ? It stops water going backward  and supposed to cool the motor down.

and supposed to cool the motor down.

The Wall on one side, is to push water into the mast. Its angeled, so i can print without supports.

Small holes in the mast act as sieve

The other side has no wall, cause there are the cables.

I was thinking that yesterday when doing the air / water test… it’s time to redesign one

I was about to get the front piece of the rotor out to see that it’s really flush on the inside.

did you measure the power when spinning it in water?

you’re not worried about lack of water circulation?

Get all surfaces as smooooth as possible. Even the stator notches can be filled without thermal worries, just leave a channel open so the wingdings get to water.

Spinning in Air: 162W

Spinning under Water full throttle: 825W

Spinning under Water half throttle: 250W

Test was with 44,4V only. (Battery wasnt charged up)

Stator and Magnets only covered with one coat epoxy. Nothing fancy, just KISS

There is a small gap, about 0,75mm, that should give enough waterflow. At least i hope so

so slight improvement compare to mine underwater… not sure if it’s the fit of the cap or may be some loss between my batteries and motor…

They say “Frischwasserpumpe” so ‘Fresh water pump’:

- do you think that sea water will be a pb ?

- is it a self-priming pump ?

Yes, selfpriming.

Freshwater… I guess seawater would be no problem. Inside it should be plastik anyway…

I’ve opened one up. It’s all plastic so salt water shouldn’t matter.

I guess anyway, everyone is using the same pump