Bravo!!! Can’t wait to see the test drive!!

Outstanding build! Thanks for sharing.

How did you strengthen the board where the aluminium box is?

Also, why use such a heavy box? I think you could have used a much lighter one.

He sure does…hence my questions… just trying to learn and understand his design decisions… so i dont go making mistakes.

Certainly no disrespect intended.

I was surprised when i read that the box and ESC was 3kg I wanted to know the reasoning behind the weight… and seeing the photo of it embedded in the board… i was thinking of doing similar but was worried it would make the board weak (as most modern boards get their strength from the outer layup)… hence my questions. Sorry maybe there was a better way of wording them.

Congrats!! That is looking absolutely spectacular.

Hello @thuffam

That’s a fair question. My Bopla box is also available in plastic. But it’s just 1kg lighter than my aluminum box.

Since the 6kg battery is on the lid of my Bopla box, I wanted the more stable version so that no water can penetrate.

I also think the box stiffens the board.

When making the cave for the box, I had to cut through the stringer. That was my biggest concern.

But thanks to the cave, I now have two standing laminated stringers and the board feels very stable.

https://www.reichelt.de/euromas-polyester-gehaeuse-360-x-160-x-91-mm-ip66-bopla-p-334-p126177.html

Amazing work Markus, on both builds! It’s a true pleasure to follow your work. Do you by chance have the step file (or stl) for the motor mount pod you used for the 63100? It looks like a newer version than what you have on printables from the Assist build.

Thx. Yes, of course. I’ll send you a message.

After the 28°C weekend, the temperature here in the Black Forest is quickly dropping to 4°C and snowfall. ![]()

So I’m still doing some tinkering on the board.

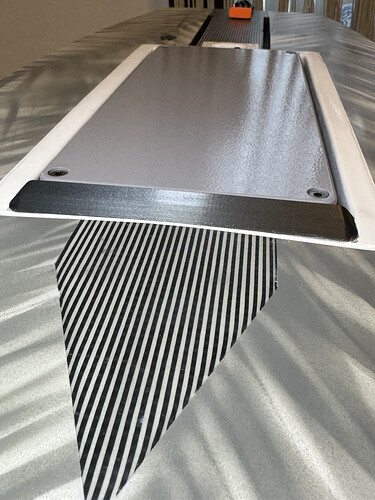

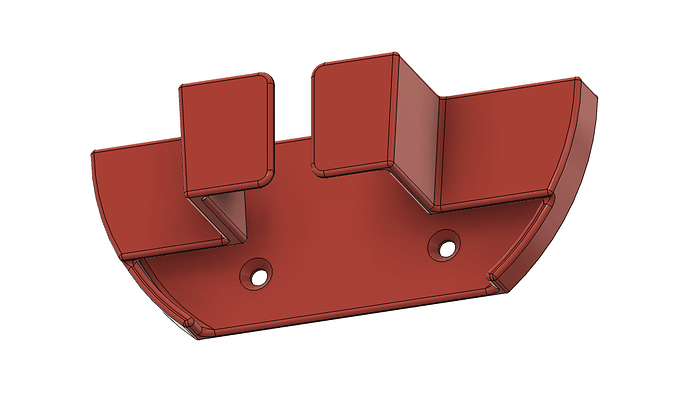

I’ve printed a spoiler for my BoplaBox.

Now no water can get between the front wall of the box and the board laminate.

The RX antenna is behind that.

I’ve also added some silicone putty in the gap in the area of the antenna.

I never get bored ![]()

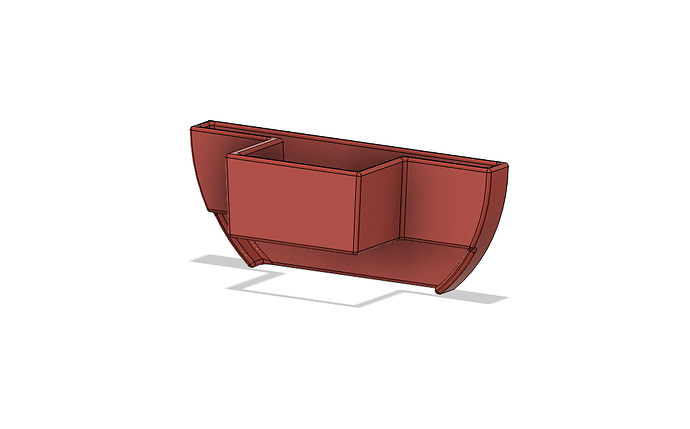

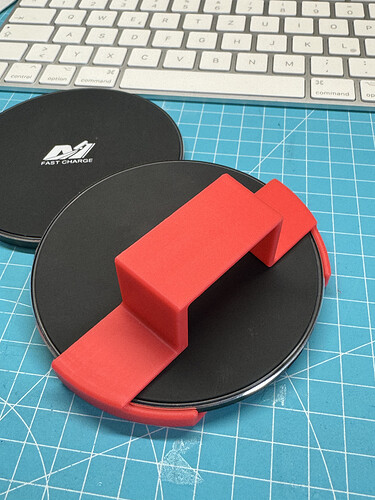

For my Maytech controller I designed a charging pad mount, like FoilDrive.

https://www.printables.com/de/model/853640-maytech-mtskr1905wf-controller-chargermount

Holder looks good, that was on my list to design but haven’t got round to it yet.

A few improvements for the remote holder would be counter sunk holes to mount the 3d print to a wall, and a slot so that you can load a remote with a strap without having to thread or remove the strap.

With that Bopla Box you always have to unscrew 4 screws. With the old plastic box you could simply swing the lid to open it. I see the advantage of the new Box but wouldn’t a BMS be practical so that you can the same cable for charge and discharge coming out of the box?

Unscrewing the box takes 30 seconds. The advantage of the Bopla is it’s 100% waterproofness and solidity. A plastic box you wouldn’t want to mount under the board!

Also with my plastic boxes I was never able to get it really waterproof. Killed an ESC with water ingress.

And to BMS or not to BMS, that’s a fundamental question in this forum. I also decided against a BMS, because of KISS. keep it simple stupid. One thing less to fail.

exactly, i’d rather not get left on the water due to a malfunctioning BMS than take a very small risk of damaging my battery. I’m moving away from BMS’s on my efoils

Just wonder what is the benefit of putting the battery in the bottom of the board? It seems to disturb an even smooth glide surface with the gap between board and battery. The battery on @hangloose boards evens seems to stick out a bit and not seems to be plane with the surface. I want to assist my wing board just in case of low or no wind. If there is enough wind I want to get on speed by “myself” to lift off. I wonder if that would not create drag which prevents getting on speed. Or this setup meant for e-folling only? I think about a similar setup but on the top of the board.

Another question I got. Is the vaccuum lamination required for stability or “just” having a clean look. I want to cut my board and just laminated with carbon mats but not vacuum it. Would that work?

That’s a fair question.

Originally I wanted to put the Bopla box in from above too. But I found the better solution from below to use the entire deck pad and not have an annoying box on top.

Since my board is only 45L and 90mm thick, it was a bit tight.

That’s why the box protrudes 4mm from the underwater hull. I don’t think I’ll have any drag problems when I see how much water FoilDrive Gen2 has to displace.

Besides, it’s only during the start phase.

It doesn’t matter when foiling.

And yes, I’ll mainly use the board for eFoiling.

In the waves as an assist with 6384 and a different mast.

To your second question:

I opted for the vacuum laminate because it’s easier overall to laminate the many corners and the laminate presses nicely everywhere.

It should definitely be more stable.

But many people laminate successfully without vacuum.

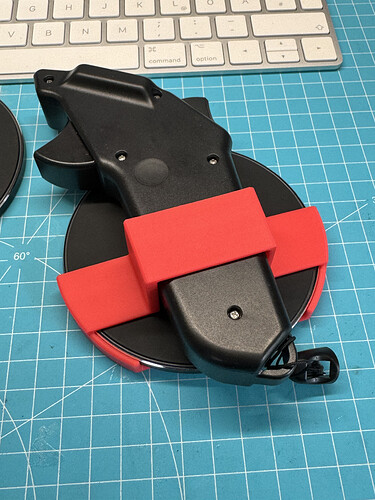

here is your Version ![]()

Wall Mount and Leash Gap.

https://www.printables.com/de/model/853640-maytech-mtskr1905wf-controller-chargermount/files

Foil Drive thanks you for your effort. They will alter slightly, print in MJF and sell it for £200 ![]()

![]()

![]()