Is it practical to just put the magnetic safety switch on the 5v line between the VESC and the receiver? In my mind that would be safe enough for a cutoff if someone falls off the board, but I guess I don’t know if that would eventually damage the receiver.

Hi, i do that in my last build like that. I configured and tested in VESC Tool the cutoff and it works great for me.

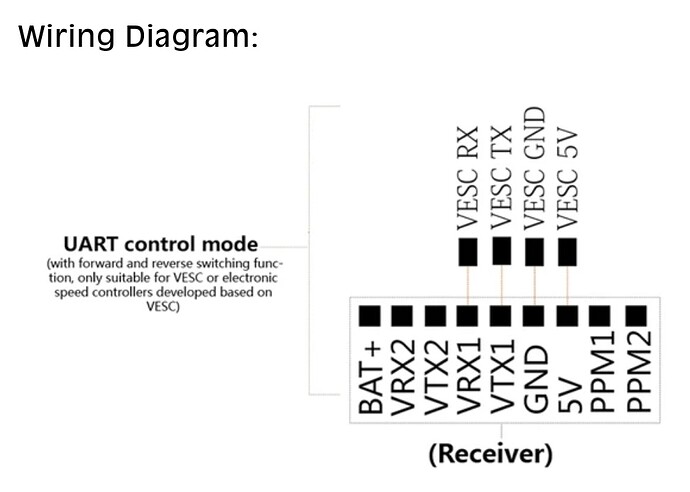

In my new build i am using the new Flipsky VX3 and it works with the UART Port and not PPM. At moment i not implemented the feature. I am not sure if it works with UART too…

Yes, but i still not tested if the mechanism is the same as in PPM

If the signal is lost, the VESC motor controller will cut out after the defined time frame.

So interrupting the signal is a method to stop the motor. However, we prefer not have fast response time, as a very short remote dropout should not immediately cut back power.

Using ADC as a safety switch is probably better. Maybe Vedder can incorporate it into the new upcoming VESC Tool 3. I will ask him about that feature.

Where do you set the defined time frame? I don’t recall seeing a setting when setting up my ESC. And when disconnected does it continue the last known throttle for the specified time frame?

Frank, did you ask him one year ago also as you said? What was The answer?

Have you asked him again, What is The answer?

The reason why i ask is because i never bought The kill switch last year because i had hope on this feature. In case of this feature it shall be a closing kill switch, in case I want to remove The power to the receiver it should be a open kill switch.

I created a feature request on vesc forum also for The same question earlier this year.

https://vesc-project.com/node/2878

One other question related to Trampa vesc. I have several of your vesc, but i do not understand why it is any conformal coating at all on them.

What is The reason for this?

The kill switch will be integrated into the new VESC-Tool BETA within a few days.

https://vesc-project.com/node/2878#comment-7778

We conformal coat them for customers who operate them near the water.

I think in surf applications you really want them in a 100% waterproof box, or even pott them in epoxi.

Coating needs to be done by hand to spare out the mosfets. It adds quite some workload to each unit.

Sounds great that the kill switch functionality will finaly reach to the software

Okay, that is news for me that you offer conformal coat as extra service. How much extra does it cost?

I would probably have bought it to the vescs I bought from you.

I agree they need to be in a extra box, but in case an accident happens, it is good to have some extra margins so it doesn’t burn up directly.

Then the waranty is gone directly when we open them up also, that is the reason why I always want to test it on the board to make sure it is working fine before I pott and put corrosion X on it

Conformal coating would not help when water gets in there. It helps to prevent corrosion in salty air.

We will not add it ourselves for a hand full of units. Just if someone wants to buy 100 units for a production model. Also oil like corrosion X has turned out to attack the heat pads from all manufacturers we tried.

So the best way is either having it in a 100% waterproof box, or pott it and throw it in a 100% waterproof box.

Hi, that’s a very important observation coming from you. I hope all forum members will read it. It is very likely that the corrosion X is attacking (eroding, sticking, etc) some plastics and some flexible seals.

Corrosion-X is not compatible with Butyl and Silicone, that’s why the heatpads degrade (they made from silicone). The O-rings and seals in the motors are made from Nitrile or Viton which would be fine with Corrosion X.

Pouring corrosion X on an ESC is just a bad idea full stop! Even potting the ESC is a bad idea.

Using a decent waterproof box means that if there’s a fault it’s easy to repair and there’s no mess or manufacturer warranty voided.

A good box with 100% sealing everything off against the water is pretty much the only way forward.

Add some silica gel pads to soak up the humidity. inside the enclosure.

@Trampa Thank you for testing with corrosionX and heat pad and reporting

Could you please look into maybe propose a vesc waterbox since many of us use and will be using your vesc and with the wires it is not easy to find something on the market

If corrosionX degrades silicone what happens to phase wires?

Nothing good. Looks like people haven’t really reported issues like that, but the CRC corrosion inhibitor I tried made a total mess of my phase wires, to the point where the motor became unusable. IMO we should stick to mineral oil. In addition to being silicone compatible, it is cheap and very easy to source from any local pharmacy.

Is it worth then filling up the motor with something, being corrosionX or mineral oil?

Or should I just rely on the motor being waterproof?

If you are talking about 65150 motor i would not rely that it is waterproof.

I run mine half season last year before it started to sound very bad.

I have now changed front bearing in it and put in some oil into it together with some grease to the sealings to protect it more.

CRC have a few products that can be consider corrosion inhibitor, do you mean the CRC 06026 or 6-66? When searching on the net found someone saying not to spray corrosion X on rubber parts as it will eat it…?

Mineral oil…mot sure what type you mean… not sure you can purchase mineral oil in pharmacy everywhere ?

Wonder about fogging oil, have use that a lot during the years for internal and external winter service for outboards, no issue on rubber/plastic/painted parts so far : Fogging Oil 12 oz

Maybe an workable alternative inside inrunner?

Mineral oil also attacks certain parts. I would say that Silicone oil is the best choice if you want to use oil.

Things always need to be tested and oil might attack things over a longer period of time, which makes testing not easier.