Have made some progress with this - and the idea is starting to make a lot of sense… I’ve added it to my build log here

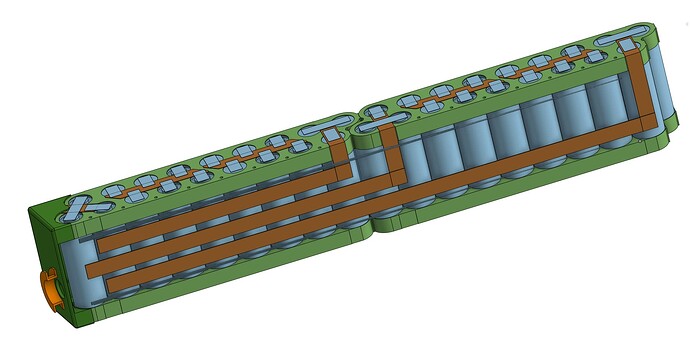

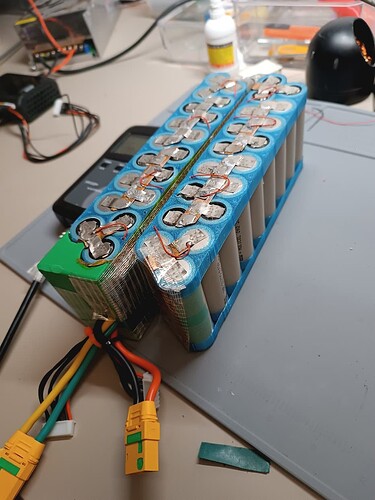

From model to reality:

Originally it was designed all to be inline to be inserted into aluminum under water, but for the box these two halves are folded.

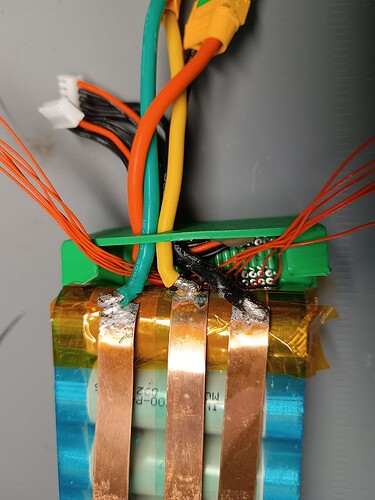

Because it was supposed to fit inside tight space, the model walls are especially thin. And used the copper strips instead of wires to keep width and height small as possible.

Under the petg end cap there is a 200A fuse and pico fuses for 14 balance wires.

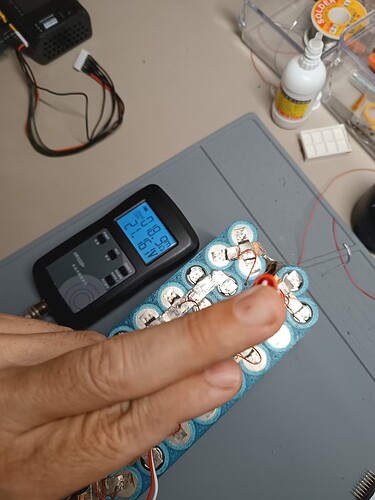

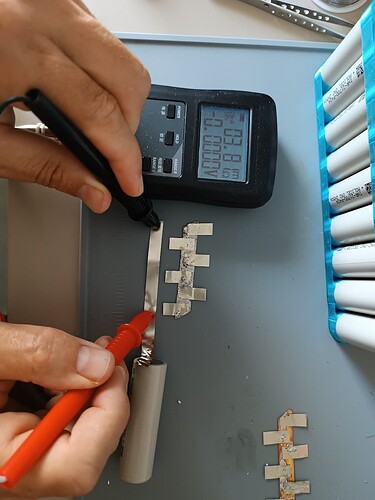

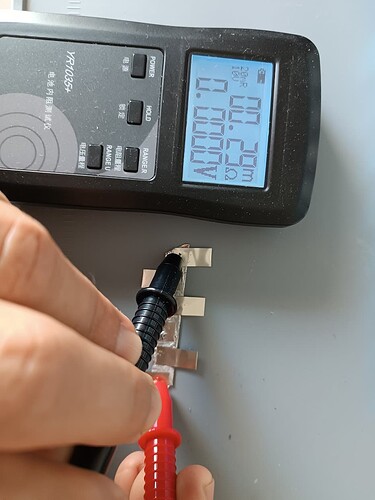

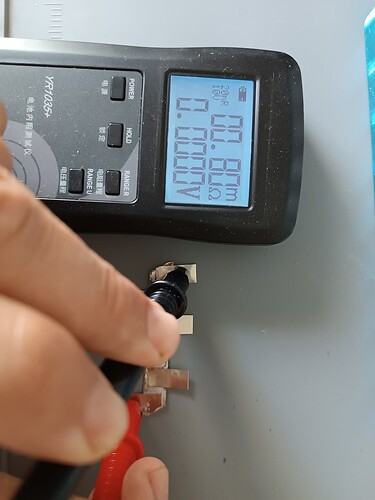

Each bank ~20mohm

Total for 12s3p batter 40mohm

Each battery ~9mohm

each connection ~0.9mohm

Comparison of 0.15X8mm pure nickel resistance vs same length copper 0.3X10mm

from battery to battery:

Used Fnirsi SWM-10. Conclusion - these kinds of products suit only non pure nickel strips.

My conlusion for next time - to solder copper strips by making holes in the strips first (and freezing the cells for any case).

Charger - ToolkitRC M6D - charging dual at 9A, excellent charger till far. Make sure to calibrate it, and then you will get accurcy of < 0.01v. Even after discharge most of the cells within 0.001v.

I recommend this internal reistance instrument - YR1030

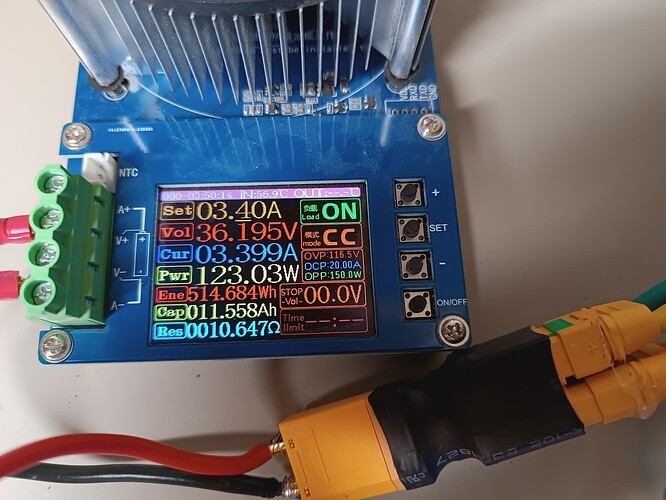

Capacity:

12s3p of Molicell P42A

460Wh of actual in the water till AFAIR 2.9v

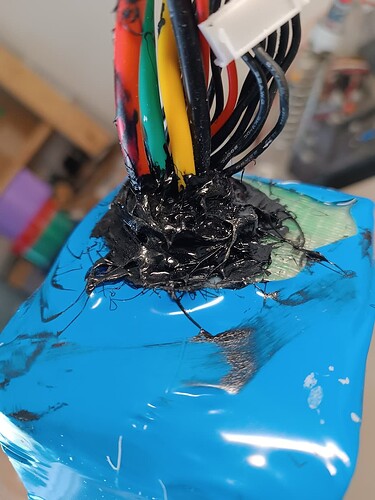

Potting compound sealing one end

The other end additionally marine silicone around the wires. Underneath these is a ring holding wires together. I should have instead sealed from inside the petg cap and made the wall around wires larger

Message me if you want to receive a link to the Onshape design. It is parametric - for example I generated the 32700 holder

Model of the holder:

Remixed model of @hangloose motor mount , suited for KT mast or of any, with some modifications.

The mount is slides on the mast by pushing. I don’t know if it is good or bad and how it should be, but if not pushing, it stays in place.

https://www.printables.com/model/901403-motor-mount-for-6384-on-kt-foil-or-any-foil

Remixed model of ThermikDreher two blade propeller:

Printed using PC 0.2 nozzle. The stl is set in an orientation ready for print and more printing instructions are there.

When I printed in low infill, it break in the second session. Now with 100% infill it held two sessions till far. Base with low infill also broke, now printed with 100% infill.

More parts:

- Box mount

- Cable exit from box holder

- Prop protector

Super glue used to glue petg parts.

Perspex glue used to glue PC parts.

Motor: 6384 from Aliexpress

- Cut the shaft

- Replaced with SS bearings

- 12AWG Cable soldered on the outside, covered with liquid tape and heashrink. (But I don’t recommend liquid tape - I think it does not adhere good to the cables and the size of the connection is too big. Need to find other solution)

- Magnets sprayed with 3 layers of epoxy primer.

VX3 Remote:

- Screws were replaced with SS M1.7/6mm

- Opened and covered antenna with lacquer

Impression: - Need to find solution for this tiny wire that that is connected to hand

- Readability was pretty good in sunlight, I saw my speed - it was nice. Though I wish the battery indication was bigger.

- It stoppes communication with being little tiny under water, almost spray.

Need narrow long bit for unscrewing:

That is not my experience with either of the VX3 I have. Sounds like a marginal signal problem that the little bit of water makes it disconnect.

Good to know.

It is when I start up on the knews on 90L board and hold both hands on the front and water covers a little the front at first seconds. Then the speed halted, but the remote not vibrates. Then I need to release the trigger and press again to engage.

After the first session I replaced the original antenna with longer one which I attached the closer side of the cover, It improved a bit , but I still have to be aware of water. ![]()

Are you talking about using a longer antennae inside the VX3 or the one connected to the VESC?

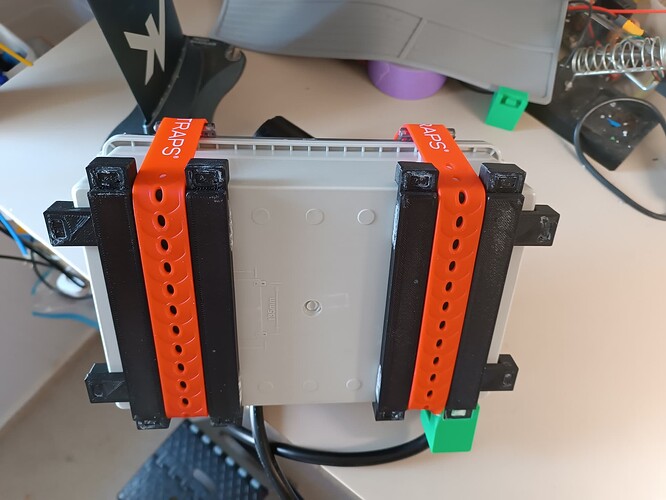

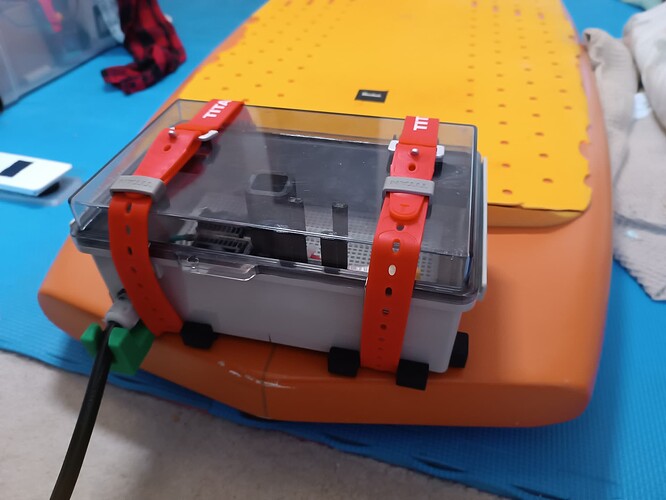

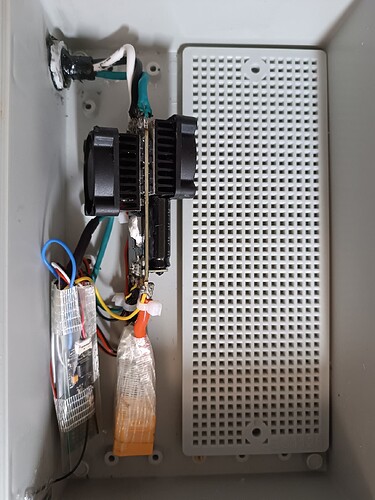

Box: 275x175x100 from Ali

The size is bigger than usual builds because 12s3p together with a fuse barely fit in the smaller box. And I wanted to experiment with Esc cooling.

Support frame is glued to the board with 3m double sided tape.

Box is held to the frame with titan straps.

Later covered the top with a shinny sticker so that to reduce sun heating the internals.

Impression:

It is pretty waterproof together with the titan straps. Seems that I got in 3rd session a few droplets of water on the cover inside , but I am not sure.

The problem with such a design when having to open a box is that while opening I everything else is covered with water so have to do it carefully. Also have to be carefull when closing to that nothing is there laying to on the o-ring.

It held well the board being thrown in beach brake.

Ergonomics:

The sharpness of the frame is not good with crawling on the board. Can be better.

The box at the back - makes harder to get knee over it and sometimes knee hits it.

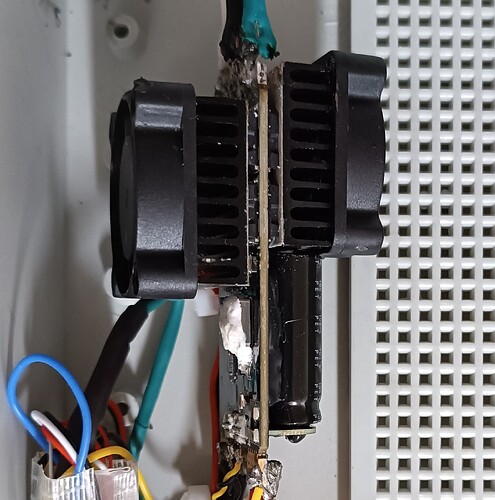

BLHeli 160A ESC

Being cooled by 5v small fans. So far so good.

Replaced the built-in heatsinks.

ESC, receiver, 5v BEC

It was a long ride - 8 months weekends, weekdays, evenings. Researching, planning, ordering, building lab, learning and practicing 3d printing. Dealing with self perfectionism.

Thank you all the people in the forum ![]() , without you it would not have happened!

, without you it would not have happened!

Eventually it flies, so all good, calling it a success.

It has shortcomings, so calling it V1.

Conclusions after 4 sessions:

- BEC broke - have to add some protection, like caps on it’s input.

- propeller broke - reprinted with 100% infill

- It helps to learn foiling in less waves, less wind - less chop. Especially important first session.

- That thing of leash tangling with the back leg when it’s being raised on the bord. I am still trying different options - connecting to calf/waist/ankle, spiral/straight/spring leash, exiting behind or before the box. Or attaching to front of the board.

- The thing with remote gets disconnected with a little under water. Nice to see vx3 speed and pretty visible in sun

- Sharp edges of the box support frame is not good

- To turn on after the foil is in the water

- When battery is close to finish , have to press more on the trigger. Idk if it is good or bad.

Shortcomings of the box and specifically box at the back:

- harder to raise the leg above

- leash tangles around the box

- far from the remote

V2 in progress - flat box on top in middle of the board

When entering with the board upside down suddenly got hit by something in the face. Then realized that it was a propeller. Apparently I pressed the trigger unconsciously.

Conclusions:

- To turn on the remote only when foil is in the water.

- I am gratefull that this is a plastic propeller…

I always put epoxy with microballons in between the magnets for that reason. I mix it really thick almost like putty so I can do it all at once and it not be runny. It will keep the magnets from shifting like that.

Yes it can be fixed, just push the magnets back to where they are evenly spaced then add the epoxy filler between the magnets.

The black is just rustoleom spray paint. I don’t put epoxy on the magnet face.

I did that as well, I used an ice cream stick to evenly distribute the thickened epoxy.

Thanks! Saved my day!

How did you fix the box base to the fone board?

Two rows of 3m two side adhesive

Here on Flipsky website, apparently some manufactuters put the epoxy between magnets.

They also say something about being quiet and balanced - what do they mean?

I will try to put super-glue with baking soda between the magnets - did anybody try it?

I’d never heard of that but the videos I’ve watched are super interesting. I definitely need to test it out and see how well it will work.

Which videos? Will you attach selected ones?

Just google super glue plus baking soda. There are loads of videos showing strange things people have glued together.