Yes they are. Although the maytech (not generic Ali) uses paint and not epoxy. Which IS not Bad per Say but a weaker option than the thermal epoxy potted like flipsky and saite or the DIY version (based ond the Ali ones) you can find in this forum.

I Can confirm that with a three blades you Can get a lot of it. (I manage to lift my 63kg with a 1250cm2 on an inflated board first session without pumping) On 12S

Thanks jezaa.jiggle I will😁

Foilguy, off topic and inappropriate as usual. He is among the 9 out of 10 people here doing the same. That’s why I will consider stopping posting here, poor community spirit. If it was up to me my whole thread would be deleted by now because it was swamped with foil trolls aka troils. Even this post is against community guidelines because when a post is flagged as off topic or inappropriate it never gets deleted. This forum seems swamped with people who wasted their time and money and who are actively seeking to put up barriers to entry to foil assist. If I do post here again I will just have to block people asap. The $1k foil assist seems possible to me and if it is technically possible, it is inevitable but I will hesitate to seek or provide help here.

I think that maybe you…are the troll… this forum is crammed full of knowledge as well as those that have given up the time to share it. You, seem to spend most of your time refuting what is now proven to work even though you dont seem to have any actual experience in any of it… ive built three foil drive systems and they all work fine…i also built them for under a 1000 bucks using some of the advice and products suggested in this forum…i also owe alot of thanks to those that helped me with CAD, wiring and battery schematics… you might find that if you were less in everyone’s face when people suggest things you might get somewhere.

Personally, i find your tone and unwillingness to listen to those with actual knowledge both annoying and frustrating.

I’d take your own advice mate and bog off elsewhere…You wont but then i expect nothing less.

K

Something unusual happened during today’s session. After a few pop-ups, the power dropped to the point where it couldn’t lift the foil. What a bummer!

- Nothing changed since the last successful session.

- There are no mechanical or electrical issues.

- I’m stumped. But next time it happens, I’ll try reconnecting the battery—it might be some kind of ESC protection function.

I’m using a 6384 motor with an Xcross 160A ESC with fans, and a 12s3p battery setup. You can check out the build here.

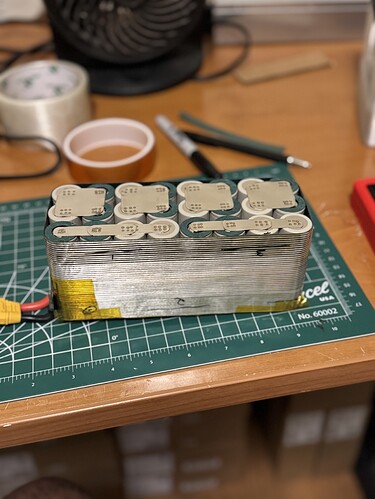

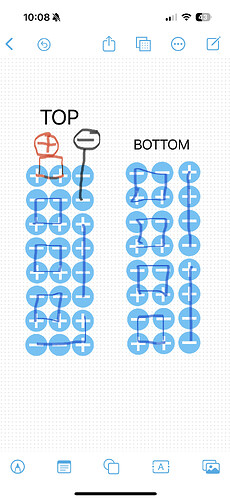

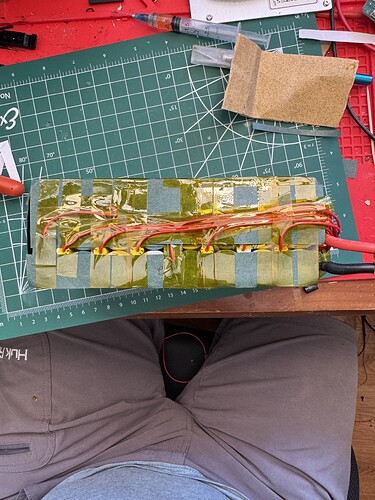

I can’t remember where it was asked about how I build my 12s2p, but I have changed the layout to keep the battery leads as short as possible. I forgot to take a picture of the top before I sealed it up, but a couple pics with a drawing. I built this for a buddy this weekend. I used .2mm nickel strip and doubled it up on the single row, so hopefully this will give the least voltage drop and heat. I also 3d printed tubes for the BMS wires to go through the pack so all the wires would be at the top. All separated by kaptan tape and fish paper where the overlap. A couple pics won’t load so I’ll have to convert them.

I wanted to do something similar but do a copper nickel sandwich on the series connections and a single nickel strip on the parallel to keep the resistance lower on the series vs parallel . Don’t know if it makes any difference on just a 2p battery ?

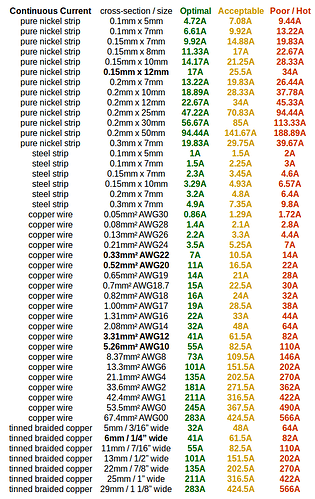

It will work and it is a clean build, but based on the power those cells supply, its is borderline. Use more for your next build or change layout to avoid single strip connections. This kind of ressource chart can give you a good idea :

I completely agree, but I’ve also built a 12s2p with just .15mm nickel strip and haven’t had any issues hammering on it, but probably getting voltage drop. So, double upped .2mm should be plenty, but maybe add one more layer of .2mm.

That is the best layout I could think of. Do you have a suggestion for a better layout? I would definitely build it. Keep in mind that it has to be in this layout for the box size.

That is super useful. I had not thought of that configurations for a 12s2p. This would replace my 8s3p perfectly in the Camden box I use.

@nekitesurfing …my.mind boggles everytime i see a battery diagram…i was never any good at puzzles!!

Agreed…a great more powerful solution for those of us using the Camden Boss boxea !!!

K

Super interested in the parts for the first pic with the yellow prop. Is that the BOM you listed just after this post?

Basically I now want to build the smallest possible assist (for wingfoiling) with the least weight on the board (smallest 6s battery to last several starts, small esc without cooling, etc) and least drag in the water (6374 or 6384, single cable through board, mounted high on mast, folding prop, etc.). If I can get the size down I may even build a cavity into the mid size board I’m about to build.

How would you use it for wingfoiling?

I have a dream to learn and to use wingfoiling (or kite, or parawing) in light thermal wind and even with a small board using the foil-assist to help get up.

I did a few tests, but couldn’t figure out how to combine them.

So when you manage to do this, please tell me.

Ha. Yeah. I’m setting myself up for lots of struggles and learning, but that’s part of the fun. There are few videos of guys using assists for starts and building up apparent wind. That and using it to ride to spots out of wind shadow and back in through wind shadow is part of the dream for me. I’ll pop in next year to report how it went ![]()

Did you ever find anything for a high current 3 pole connector? I too am just about to start a new board build and would love to have the motor-to-esc connection running though a hole in the board rather than directing it under and over the board.

There have been some clever custom solutions here with individual bullet connectors, etc. but they seem to add up to a significant diameter. Would love to keep the hole through the board as small as possible.

Also: It seems like the original foil assist had motor cables combine into a single 3 conductor cable near the motor. This cable seems like it’d be around 14AWG. Or at least much less than the large motor lead wires. How is this possible without overheating? Is this whey some seem to be getting away with MT60’s? The math doesn’t add up ![]() But curious how others are handling dropping down to a single cable between esc and motor.

But curious how others are handling dropping down to a single cable between esc and motor.

For science, I tried the combination of wing foiling and an efoil assist and found it really difficult to balance the large force of pulling/balancing myself with the wing combined with the fine trigger dexterity on the trigger. There was also extra weight from the assist system which I didn’t like when wing foiling and so I had more fun doing one then the other than combining them both together.

Awesome to hear but sad that it didn’t feel good. Would love to know more about your setup: Board size/volume, wind strength you were out in and what your assist system is roughly.

Maybe the parawing will be answer (when Gong develop low cost version)

Born Kites WaveStar or FoilStar