nope, never luckily.

I hope so as well. I called Fliteboard and send them pictures. now they wanted to have pictures of the mast and some kind of number I could have only gotten out of the Fliteboard-app. But I don’t use any other components from Fliteboard except from the board…

I told them that, will wait what they have to say about that. I have a feeling that because I am not using their components they might say it has to do with that. On the phone the women told me that it will probably be covered by warranty, but now that they know I am not using there stuff I am not so sure anymore…

Will see and I hope for the best.

I checked after I discovered the crack and all screws were equally tight, tight enough but not too tight. I also think that’s an manufacturing issue…

I thought about that too, but it can’t be that Fliteboard produces a board that barely holds together when using their components. Others jump with that thing and ride it in waves, a 10cm longer mast can’t be an issue. Also I am a very light rider, not more than 67kg. I have seen people ride an e-foil with well over 100kg of rider weight…

Also the board is brand new, bought it from Fliteboard directly, in august last year. Only got around the finish the electrical stuff a few months ago… Quite a bummer…

@David David Trewern the CEO of Fliteboard has been a member of this forum for years.

Fliteboard has a long standing policy of selling board only which is a logical fit for the DIY community and has an outstanding customer service reputation. Hope it works out for you

sadly it didn’t. Here’s what they wrote me in their mail:

Hi XXXXXX,

Than you for your answer.

Unfortunately, the warranty does not cover the repairs for using another eFoil on a Fliteboard, as the board was not used as intended and designed for.

To prevent the crack from worsening, we recommend having the board fixed. You can take it to a surfboard repair specialist or an authorized Flite Center (check out the map of our partner).

I’ll go ahead and close this ticket now, but feel free to reach out if you have any other questions.

Best regards,

XXXX XXXXXXX

Fliteboard Europe

Customer Experience Team

Ever fallen and landed on the board?

Nope, never. Luckily. That would have hurt…

I assume the board is manufactured from cobra as most surfboards are. Even they have some monday production that you would not expect from flite…Good news, someone with carbonfibre experience can easily repair it;-)

I made a wrong assumption, this is all wrong then, sorry …

Here is my 2 cents,

The fact it has broken at the back of the board confirms that you have not hit anything. I am thinking that the extra length of the Mast and the foil you have on the end is creating a lot of nose up pitch. Then you counteract it with weight. How much do you weigh and how forward were you on the board when you were riding it.

look at the videos of people your size riding fliteboard’s and where you were standing. When I designed my board I was cautious of this because of my weight and where the foil balanced. So my back foot is top of the mast to rearward of the mast. This balance point can be controlled by your foil setup.

So when you get it fixed (and its not a hard fix) you may want to change your foil setup.

I way 58kg and yes, it is broken at the front. I also mounted the mast again and pushed the mast with quite a lot of force into all directions (so that the mast itself bend) while standing on the board. I did not see the crack increasing or anything lifting. I hope it is some kind of cosmetic damage because of production failure. I will try to fix it myself.

I will keep you guys updated.

Can you post some photos of the inside of the cavity when you remove the box and before you start the prep to remount the box.

I’m curious about how the box is mounted during production.

Hope your repair is successful. ![]()

Flite has sold thousands of boards, and from the various forums i follow this is an uncommon failure mode with normal use.

This could happen if the mounting bolts are too long, and bottom out in the bottom and would cause a split.

Have you tried inserting the bolts without the mast plate to see how deep they can go?

Exactly this.

The other option could be the adapter from mast to board is not perfectly flat and once tensioned is pulling that corner up.

Well that is good news,

Good luck

Watch the video above as posted by Kian.

I watched this about 6 months ago just prior to making board 2. I was surprised its only a plastic box epoxied in .

This is what it looks like to me anyway.

Thanks for your suggestion to watch the video but I already have and it’s not what I requested from @maninjo so doesn’t help me much.

The Fliteboard board is the basis for quite a few builds - myself included so I have a vested interest in knowing how the board was put together in the first place.

Photos of the area that the box fits in would be helpful to a number of us as this type of box tearout could happen to any of us during a grounding etc.

Thanks for all the input!

I will try to cover some questions and will share some more photos.

@Strongarm suggested, that my screws could be too long. I think it’s a valid concern but according to my measurements I still have about two millimeters of space. That’s probably at the lower end of the recommended spectrum, I might shorten the screws in the future.

Here are some pictures:

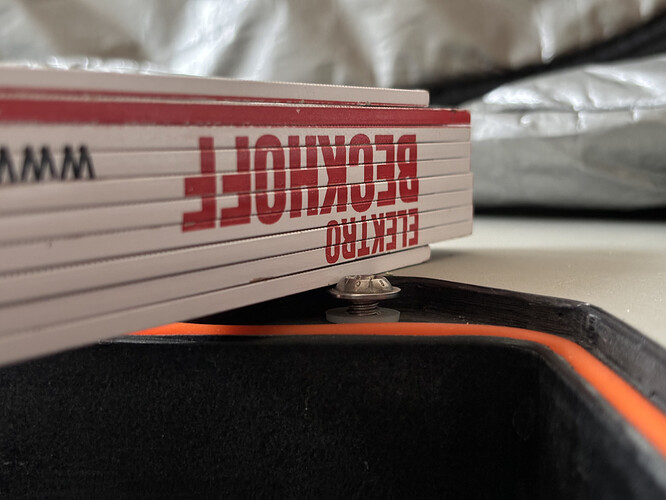

The adapter plate is more or less flush with the board. I am able to screws the screw below that point plus I also always use a nylon washer. So there definitely must be a little space.

Another thing @Jezza suggested, is the adapter plate not being perfectly flat. I checked the flatness with the flat side of a level and I can see no gap, meaning it is dead flat.

I also tried to widen the gap to have a look underneath. But I could not see anything.

Than I mounted the mast again and started bending it vigorously like a couple of times before. Here is the video. At the end of the video a loud crack is hearable. It might be that I broke it even further, but still, the crack did not widen and I was not able to see the fiber lifting…

I bought some Resin, type L285 and the hardener H285. @Raul suggested it to me. Thanks! I will try to get it under the crack and glue it back like that. Do you guys think that that could be enough? Or should I rather take the whole mastbox out and put some more layers of fiber glass on top?