I would think when the motor cools it will solidify.

ok, i think about using the same process as clarifying butter. To get rid of water and other volatile compounds, just heat it up to the right temperature. Might be easier than vacuum.

all of the above works best…vacuum, heat and filter. I agree it sounds like a good process though.

I have 2 efoil designs now…one with oil filled chamber and the other running directly in water using your motor. I stalled out on the board. Everything else works great.

Once I figure out what to do about a board, I will post all that I’ve done. I want to share like the rest of you great people! The sharing community lifts everyone up to a new potential. Its pretty cool.

I actually have a blank that’s been CNC’d…I’m just reading now how to shape and glass. I’m sure its not too tough though…

cheers

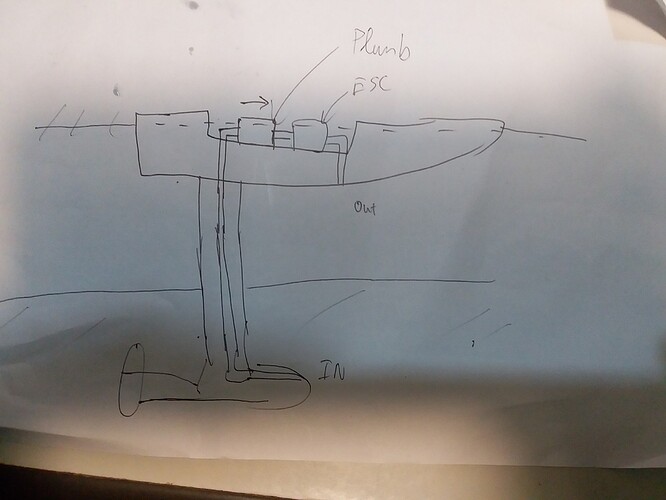

The most reliable way seems to be with water cooling. Mine uses a combination of water pressure and a small diaphragm pump. The scoop has a smaller hole for the water to escape than enter thus creating pressure when the board is moving and electronics need most cooling. There is a coarse filter that stops anything that could block the intake tubing but doesn’t affect the flow to much.

To ESC expert: is there a link between ESC heating up quicly and Duty Cycle ?

During the static tests, the motor maxed out so the Duty Cycle stayed low: 35%.

Does a low Duty Cycle generate more heat on the Mosfets/ESC ?

Well, there are some effects causing heating different components

-

Low duty cycle and low rpm, while high load makes it hard for the ESC to keep on track (since we use sensorless motors), that can also be seen, if you start the motor and have some resistance, the motor might jitter till the first revolution. Since typically the currents are low, this is not really an issue, still you might see some current spikes (after a wrong commutation).

-

50% Dutycycle is bad for the caps, since they must buffer/deliver the most energy at 50% duty, so this is when the caps can get really hot.

-

High (phase) currents. Phase current is independent of Duty cycle. Phase current directly transfers to torque. So whenever you have a high torque load, no matter what the duty is, you will have high currents and thus a lot of heating at the resistance (like shunts and Mosfets) of the ESC.

What does that mean? You made thrust test and the esc limited the motor at 35% duty, so it maxed out?

Thanks for the answers

Yes, I did a static thrust test. I designed a propeller with a pretty high pitch, so it maxed out at 34%,105A motor and 40A ESC

This is my setup for cooling. Electronics box have a small gap to board, this is fed with water through the pipe in the top of the top picture. Controller is mounted with an alu plate towards the water.

I must say that passive/active water cooling with a water pressure fed hose inlet in mast is the cleanest way to get the cooling.

-cheap

-light

-effective

-easy

Wouldn’t bother getting either pump, thermostat or any other stuff, more failure points added.

Please help me. I want to know how can the plumb take water from altitude(height)?

In fact does it always work continuously?

As long as your board is moving forward and the water line is open to the direction of travel there will be plenty of water passing through.

Can you show me some photos or videos in that the water through out the board from height

Could you please explain more about the potential for spikes … and frying the ESC with long battery wires? I would like to have the ESC in the mast which would require running 1m power cables between battery and ESC. I take it going to 8WG won’t help? Therefore, what capacitors and where? Thanks …

Hi @pacificmeister, I have a quick question: what is your opinion on a 150a esc using it with two 22ah lipos in parallel? (22V) Will it drain too much current for my SS motor (the same you used for your first documented prototype, but without gear ratio!)

I would be glad to hear from you.

Kind regards from switzerland

Hey, I am having similar design with my VESC against aluminium plate. How would you recommend to apply thermal paste as I have gaps between the fins of my vesc? Should I fill all the gaps with thermal paste?

thanks!

Mill them down. 20 char

i see, i could try to remove them with a dremel

It should be as flat as possible for good heat transition.

Those fins on the esc case are really meant for air cooling (or convection cooling). There are even holes there for mounting a fan. For using conductive cooling, in this case metal to metal, you want the surfaces to have as much contact as possible. Thermal paste is really just to fill microscopic imperfections between two “flat” surfaces to eliminate small air gaps.

You could try to dremel it down and get those surfaces flat, I think that sounds like a lot of work.

I think a simpler approach would be to just get rid of the case entirely. Put the naked esc against your aluminum surface with thermal paste, maybe a spot to glue to hold it in place. Then place a junction box (or 3d printed box) with the bottom surface cut out over the esc. The box can be glued down onto the aluminum surface, holes with cable glands can be added. This approach has been used on some of the Fliteboard adapter plate builds

This is what mine looks like:

pls dont post on a thread that has been dead for years. sends hundreds of ppl emails.