I changed it. You can try it

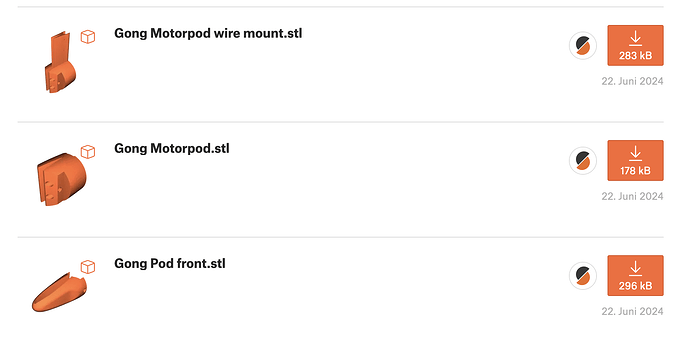

Oh yes please share the gong v2 ![]() many have Gongs and can really use this. On top Marcus’s design Is one of the very best I think.

many have Gongs and can really use this. On top Marcus’s design Is one of the very best I think.

I now also have a Gong V2 version online!

https://www.printables.com/de/model/620724-motorpod-for-6384-gong-v2-slingshot-hoverglide-axi/files

Hello Markus,

The spot welder you use, what model is it?

Is it something like this?

https://www.aliexpress.com/item/1005006869889455.html?spm=a2g0n.shopcart.0.0.30b138daD9IbDo&mp=1

Mega:+1:![]()

![]() thanks a lot!!!

thanks a lot!!!

Thanks for the quick response.

It probably is.

It is twice as cheap on Aliexpress…

I’ll try my luck from there.

Hello, you glued the new esc with heat adhesive ?did you mean the one out the ![]() pistol ( Heißkleber)? Not some thing special that guides the heat very well? And also I ask myself on the latest pictures that the cables run through the mast now? Did you therefore adapt the mast clamp? Thank you very much in advance!!!

pistol ( Heißkleber)? Not some thing special that guides the heat very well? And also I ask myself on the latest pictures that the cables run through the mast now? Did you therefore adapt the mast clamp? Thank you very much in advance!!!

Hello. I used thermal adhesive for the Jive ESC.

For the mast with the 6384 in eFoil position I used my MotorPod from the 2nd build. The 63100 has the same mount as the 6384.

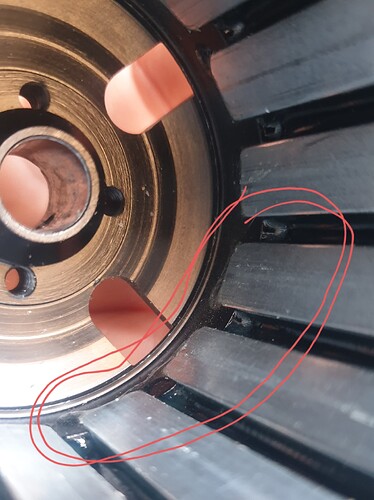

Please advise: at the bottom of the bell, the magnets for partially covered with some resin.

Do you think I need to do more?

I would leave it as it is.

my thoughts exactly…thanks

@hangloose have you used the 2.5mm2 wires for both sides since the plugs in printables only fit these wires (not the 4mm2 ones)?

Or would you still recommend going with the bigger ones on the motor side?

I had so many changes to my setup. But yes, the 2.5 is enough for both sides. FoilDrive also has 2.5

I also created a first remix version of your great motor pod for the Gong Allvator V2 in a slim version like the Axis/Slingshot one.

https://www.printables.com/de/model/920053-motorpod-gong-allvator-v2/files

Wow, great thread! I need a axis motorpod for 90cm length mast and 6374 maytech motor. Can anyone elaborate on the different types of screw configurations for different motors such a maytech 6374, 6384, flipsky, and foil drive? Or do they all have the same screw bolts size configuration to mount the motor to motorpod? Thx

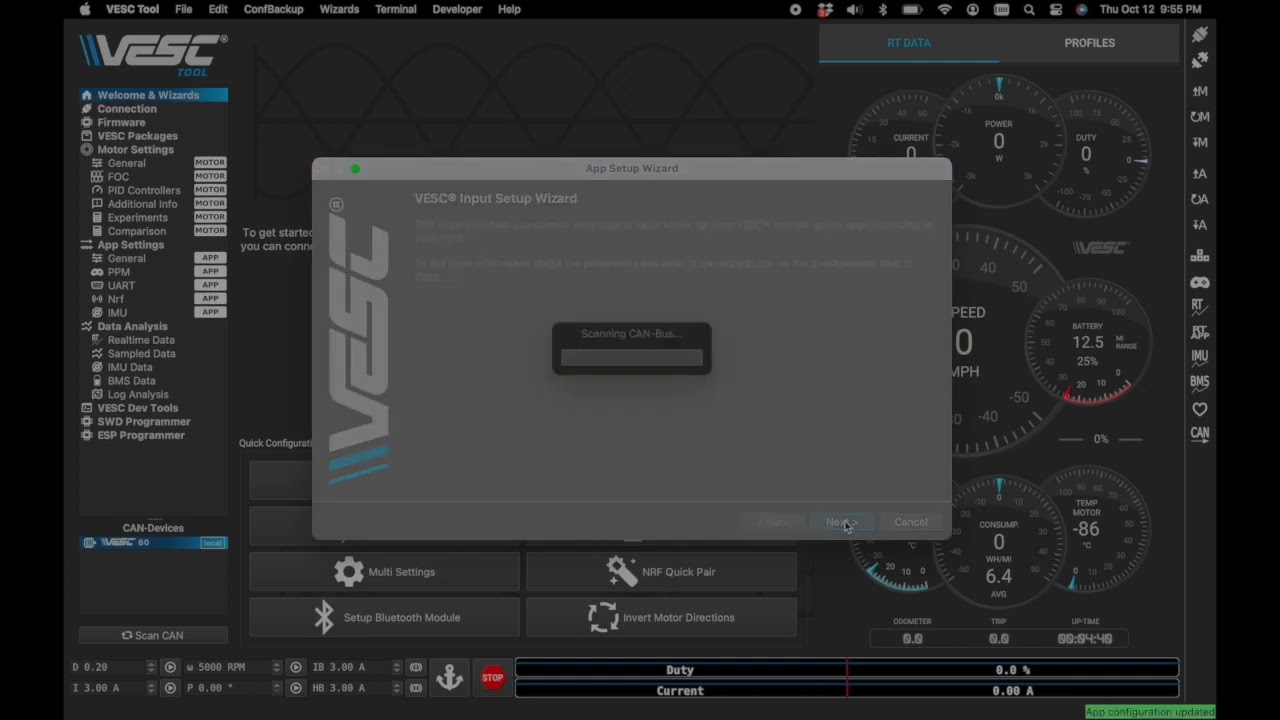

My VESC software isn’t detecting correct motor parameters. Could you post your readings you get for your cheap 6384s?

I can’t remember what mine are and I don’t use VESC’s anymore, but this is a video of how I setup my faux drive. Hopefully it helps.

Edit: I still have one VESC and if I get some time I will run through it and see what it gives me after running the detection.

I intend to make custom silicon sleeve for MT60 and for XT90. It will wrap the female part. The male shroud will be stripped. New male shroud will be part of the box housing.

Ring Similar to this:

First time using silicon. Which silicon to use?

What tips can you give about the process or maybe you have some suggestions…

Thanks

I always print negative shapes with a wall thickness of 0.8 and a layer height of 0.1. After the sealant has hardened, remove the 3D print with a side cutter. No release agent is needed. I use silicone from TrollFactory.