Cool…i was missing your builds !!!

Yes, sandpaper. The thermal epoxy sands very well.

Maybe create a holder/shaft to put it in a drill press and then sand it or use a file.

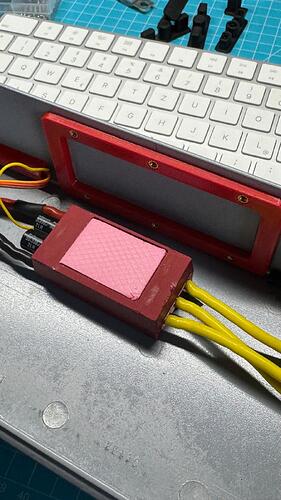

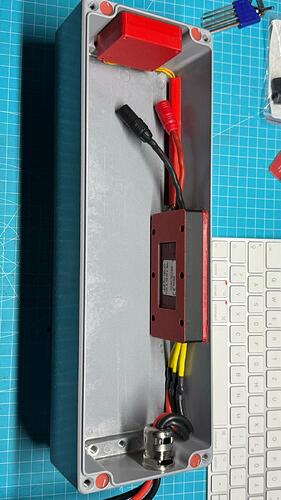

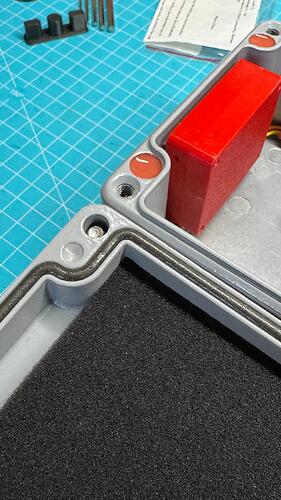

Bopla A124

360x120x81

https://www.reichelt.de/de/de/alugehaeuse-360-x-120-x-81-mm-ip66-bopla-a-124-p126154.html?r=1

That enclosure is IP66 rated. do you add additional waterproofing to it before you countersink it into your board?

No, I don’t seal anything additionally. The box works very well with the integrated seal. With my second build and the same box, just a little bigger, I was on the water for 50 hours without a drop of water in the box.

Hi Markus, like others I am in awe of your builds and attention to detail. I’m starting out on my first project, where I’ve taken much inspiration from this thread.

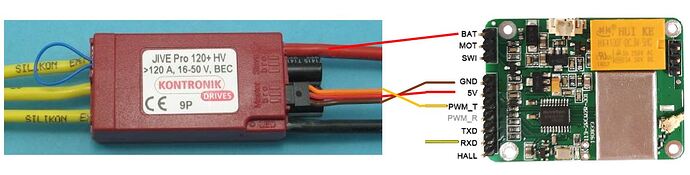

I’ve also decided to go for a Kontronic Jive controller. I am slightly struggling to plan the wiring, in part I think due to poor (or poorly translated at least) manuals for both receiver and the ESC (for which there is a lack of a proper diagram and wires are not fully labelled). Noting you did an earlier wiring when using the Flydragon, did you have one for when you upgraded/for your E-Foil build?

Thanks Markus, much appreciated ![]()

Is the 21700 battery pack STL file shared somewhere? I’d love to get the 8S3P file please?

Until now I didn’t have the files online.

But now you can find the racks here:

8S3P / 10S3P / 12S3P

https://drive.google.com/drive/folders/1seshUlOD6RxjqefX59ZGDMzFvaJSIhTK?usp=sharing

@hangloose I don’t quite understand this part. After soldering the bullets, you then heated the bullets to melt them into the inserts to form a seal before injecting epoxy? Why do you need an aluminum sheet? Also, have you used standard epoxy resin here? I assume it doesn’t need to be thermally conductive?

Hello.

The gold contacts are not melted. When the cables are soldered on, I use 2K glue and glue the gold contacts into the printed part.

Only then is the connector filled or sealed from behind. Thermal epoxy is not necessary.

I still had some left that I wanted to use up.

If you use thin epoxy, you have to fill the female gold contacts with wax first because the gold contacts have a vent.

If you forget to do this, the epoxy will run into the female gold contacts.

I also printed my own blind caps for assembling and filling the printed parts with epoxy. I screwed the blind caps onto the aluminum sheet as a device for the connectors.

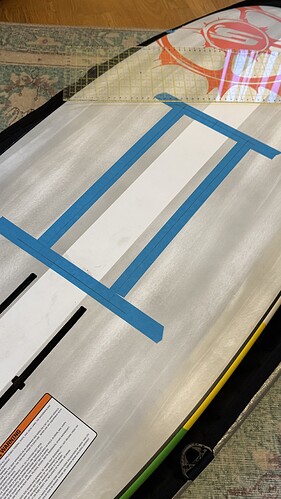

The plan is in place.

In the next few days we will be working on the cutout for the Bopla ![]()

This won’t be fun. 15 foot strap inserts have to go. Most of them are probably in a plate. We’ll see what comes out inside.

okay thanks, I understand now, this was how you kept the assembly upright during pouring and curing.

Hi Markus, thanks for sharing! I was wondering what you did with the shaft, did you just cut off the protruding bit that would be facing the mast normally, or did you rotate the shaft so that is comes through the propeller? I started to rotate, but now i’m wondering if its even needed at all. I guess the worst that could happen is ‘breaking’ sharply and the prop pulling the rotor bell off.